Manufacturing method for solid aluminum electrolytic capacitor

A technology for electrolytic capacitors and manufacturing methods, applied in solid electrolytic capacitors, capacitor parts, capacitor casings/packages, etc., can solve problems such as affecting the electrical properties of capacitors, insufficient polymerization, and inability to effectively remove solvent components, so as to avoid damage. , the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

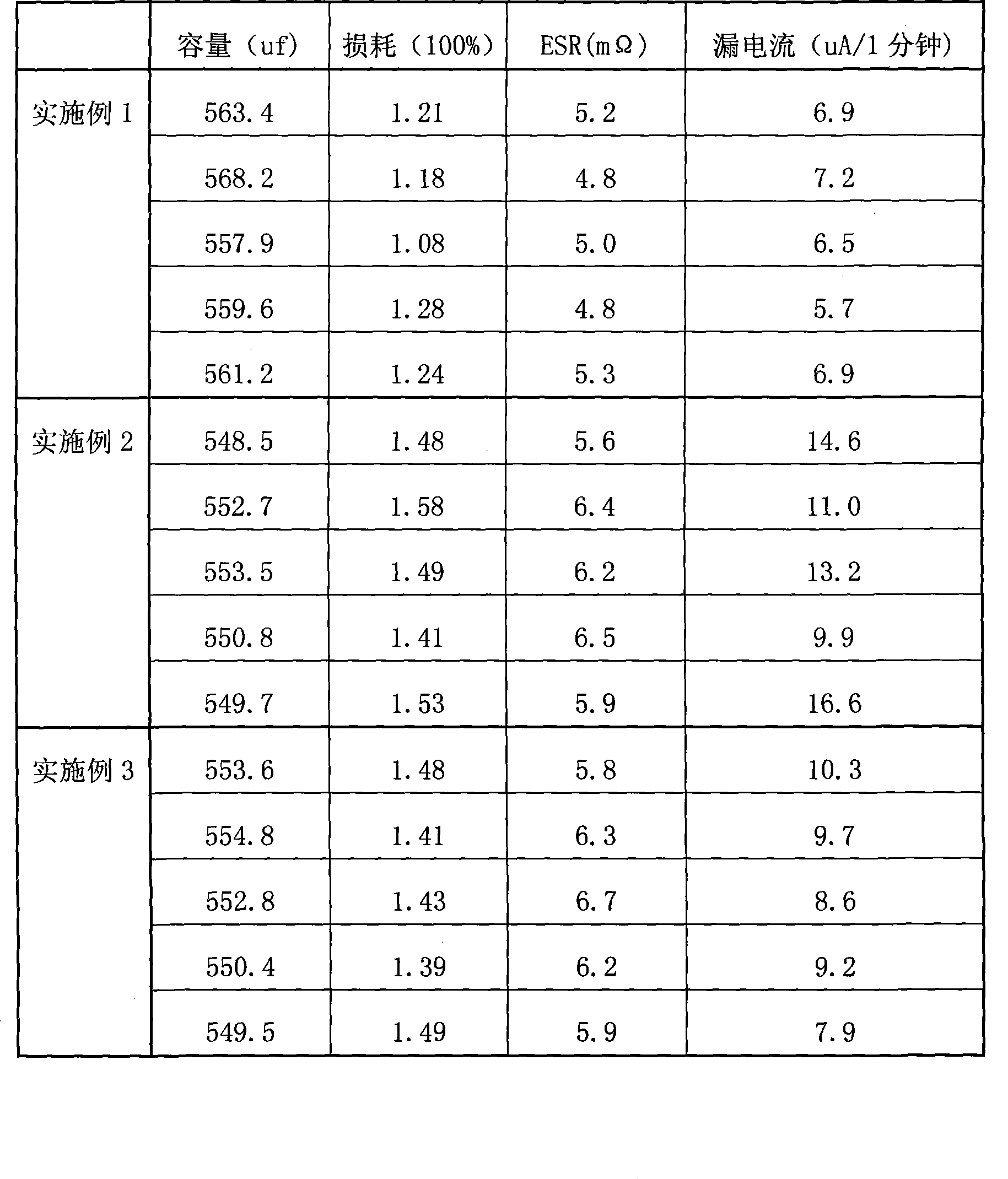

Examples

Embodiment 1

[0028] 1. Anodized aluminum foil, cathode anodized aluminum foil, and electrolytic paper are wound into a core pack through a core wrap winding machine. The electrolytic paper is between the anodized aluminum foil and the cathodic aluminum foil, and the length of the electrolytic paper is longer than that of the cathode anodized aluminum foil. long in length

[0029] 2. Put the wound core package into the chemical solution, apply DC voltage to repair it, and the treatment time is 10 minutes. Note that the core package cathode and anode lead-out wires cannot be immersed in the chemical solution, so as not to cause corrosion and affect welding performance; The chemical forming solution is ammonium adipate aqueous solution; the core-packed chemical forming is helpful for the oxidation film layer on the surface of the aluminum foil to be repaired;

[0030] 3. Carry out carbonization treatment on the core package, the carbonization temperature is 300°C, and the carbonization time i...

Embodiment 2

[0037] 1. Anodized aluminum foil, cathode anodized aluminum foil, and electrolytic paper are wound into a core pack through a core wrap winding machine. The electrolytic paper is between the anodized aluminum foil and the cathodic aluminum foil, and the length of the electrolytic paper is longer than that of the cathode and anodized aluminum foil. part length is long;

[0038] 2. Put the wound core package into the chemical solution, and apply DC voltage for repair treatment. The treatment time is 10 minutes. Note that the lead wires of the core package cathode and anode cannot be immersed in the chemical solution, so as not to cause corrosion and affect the welding strength. ;The forming liquid is an aqueous solution of ammonium borate; the core-wrapped forming helps to form the oxide film layer on the surface of the aluminum foil for repair;

[0039] 3. Carry out carbonization treatment on the core package, the carbonization temperature is 320°C, and the carbonization time i...

Embodiment 3

[0046] 1. Anodized aluminum foil, cathode anodized aluminum foil, and electrolytic paper are wound into a core pack through a core wrap winding machine. The electrolytic paper is between the anodized aluminum foil and the cathodic aluminum foil, and the length of the electrolytic paper is longer than that of the cathode and anodized aluminum foil. The length of the part is long;

[0047] 2. Put the wound core package into the chemical solution, and apply DC voltage for repair treatment. The treatment time is 10 minutes. Note that the lead wires of the core package cathode and anode cannot be immersed in the chemical solution, so as not to cause corrosion and affect welding strength; the forming solution is an aqueous solution of ammonium dihydrogen phosphate; the core-packed forming is helpful for repairing the oxide film layer on the surface of the aluminum foil;

[0048] 3. Carry out carbonization treatment on the core package, the carbonization temperature is 200°C, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com