Position and flow double-close-loop direct-drive volume control electro-hydraulic servo system

An electro-hydraulic servo system and volume control technology, which is applied in the field of electro-hydraulic servo, can solve problems such as low volume efficiency, oil replenishment mechanism and hydraulic lock opening time delay, etc., and achieve simple control, simple and compact structure, and eliminate inherent defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

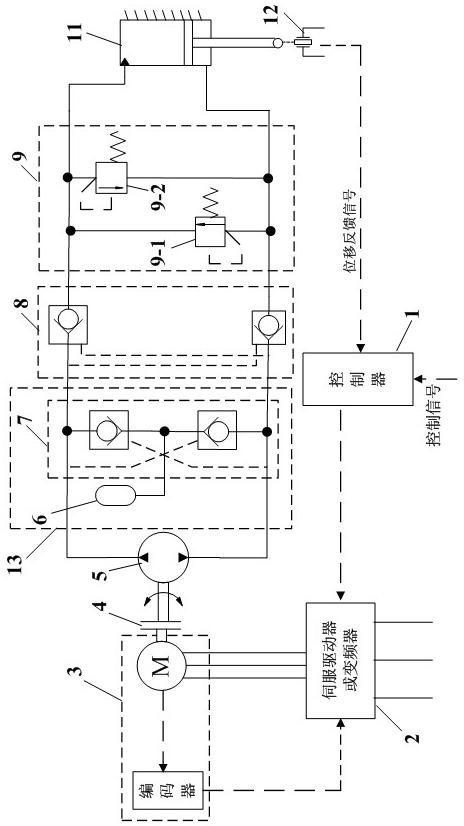

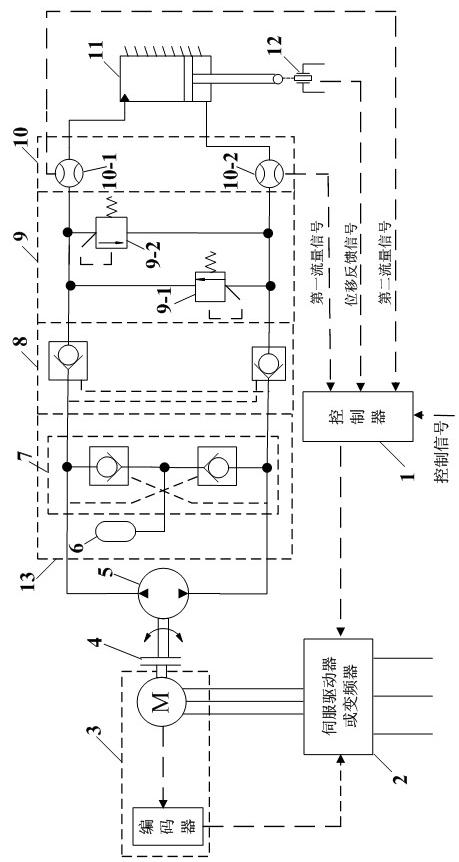

[0009] Specific implementation mode one: combined image 3 Describe this embodiment, which includes a controller 1, a servo drive or frequency converter 2, a servo motor 3, a two-way quantitative pump 5, a hydraulic lock 8, an overflow safety mechanism 9, a flow sensor 10, a hydraulic cylinder 11, and an oil replenishment mechanism 13 and a displacement sensor 12; the controller 1 is provided with four input terminals and a control signal output terminal, and the four input terminals of the controller 1 are respectively a control signal input terminal, a displacement feedback signal input terminal, and a first flow signal input terminal terminal and the second flow signal input terminal; the control signal output terminal of the controller 1 is connected to the control signal input terminal of the servo drive or frequency converter 2, and the control terminal of the servo drive or frequency converter 2 is connected to the controlled terminal of the servo motor 3, and the servo ...

specific Embodiment approach 2

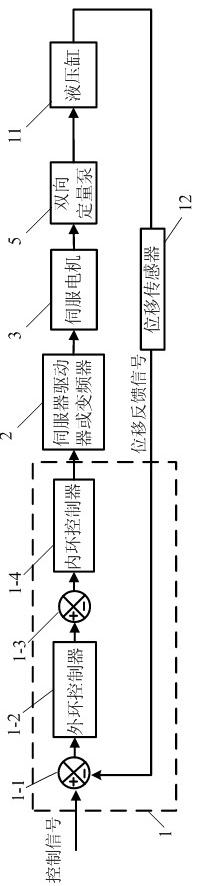

[0010] Specific implementation mode two: combination Figure 4 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the controller 1 is composed of a first comparator 1-1, an outer loop controller 1-2, a second comparator 1-3, an inner loop controller 1- 4 and a signal processor 1-5; the first comparator 1-1 is provided with two input terminals and a signal output terminal, and the two input terminals of the first comparator 1-1 are respectively control signal input terminals and The displacement feedback signal input terminal is the control signal input terminal and the displacement feedback signal input terminal of the controller 1; the signal output terminal of the first comparator 1-1 is connected to the signal input terminal of the outer loop controller 1-2, and the outer loop control The signal output end of the device 1-2 is connected to an input end of the second comparator 1-3, and an input end of the second comparator 1-3...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment 1 or 2 is that the oil replenishment mechanism 13 is composed of a closed oil tank 6 and an oil replenishment valve 7; the two oil inlets and outlets of the oil replenishment valve 7 are respectively connected to the On the two oil lines between 5 and hydraulic cylinder 11, the third oil inlet and outlet of oil replenishment valve 7 are connected with the inlet and outlet of closed oil tank 6. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com