Additive for ultimate formation liquid of middle and high pressure formed foil and adding method thereof

An additive and chemical-forming technology, applied in capacitors, circuits, electrolytic capacitors, etc., can solve the problems of large rise in boost time, affecting aluminum electrolytic capacitors, and sophisticated production, and achieve the effect of stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Medium voltage 200Vf formation. The medium-pressure corroded foil is boiled in pure water for 5 minutes, then in the formation solution containing boric acid, citric acid and its salts, the first-level constant pressure 70V formation is carried out for 10 minutes, the second-level constant pressure 170V formation is 10 minutes, and then the boric acid and its salts are formed. The main solute is formed by adding 0.500wt% sebacic acid as an additive to the third-stage constant pressure 180V formation solution for 20 minutes. Then heat treatment, intermediate treatment, repeated chemical conversion 3 times, and post-treatment.

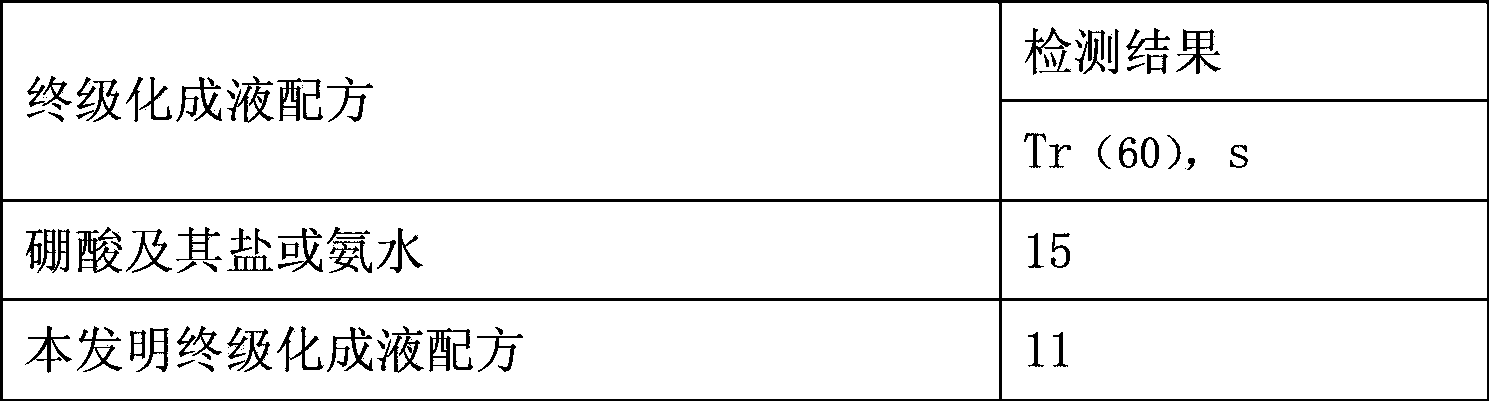

[0013] Test data of chemical foil produced by different final chemical liquids:

[0014] Table 1

[0015]

[0016] From the experimental results in Table 1, it can be seen that the boosting time Tr(60) after hydration resistance of the chemically formed foil of the present invention is shortened by 4s compared with that of the prior art.

Embodiment 2

[0018] High voltage 530Vf formation. The high-pressure corroded foil is boiled in pure water for 10 minutes, and then in the formation solution containing boric acid, citric acid and its salts, the first-level constant pressure 150V formation is carried out for 10 minutes, and the second-level constant pressure 300V formation is 10 minutes. The main solute is boric acid and its salts. , adding 0.05wt% azelaic acid as an additive to the formation solution for the third stage constant pressure 450V formation for 10 minutes; then boric acid and its salt as the main solute, adding 0.03wt% ammonium hydrogen azelate as an additive to the formation solution for the fourth stage Level constant voltage 505V for 25 minutes; then heat treatment, intermediate treatment, repeated formation 3 times, and post-treatment.

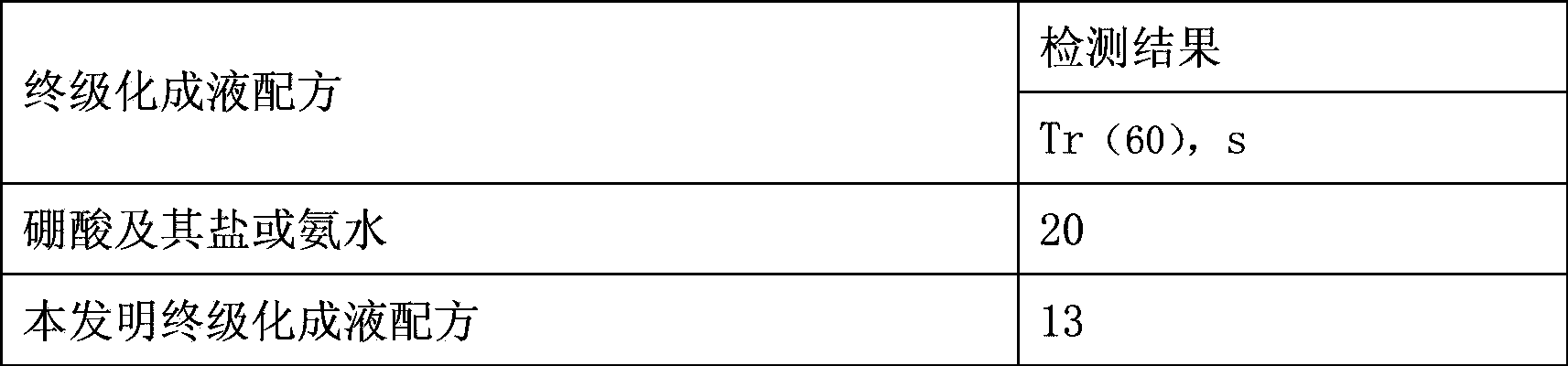

[0019] Table 2

[0020]

[0021] From the experimental results in Table 2, it can be seen that the boosting time Tr(60) after hydration resistance of the chemically for...

Embodiment 3

[0023] 660Vf formation. The high-pressure corroded foil is boiled in pure water at 95°C for 12 minutes, then in the formation solution containing boric acid, citric acid and its salts, the first level of constant voltage 200V formation for 12 minutes, the second level of constant pressure 400V formation for 12 minutes, and the boric acid and its salts As the main solute, add 0.03wt% azelaic acid as an additive to the formation solution for the third-stage constant pressure 600V formation for 15 minutes; then use boric acid and its salt as the main solute, add 0.01wt% ammonium hydrogen azelate as an additive to the formation solution Carry out the fourth-stage constant voltage 640V formation for 30 minutes; then perform heat treatment, intermediate treatment, repeated formation for 3 minutes, and post-treatment.

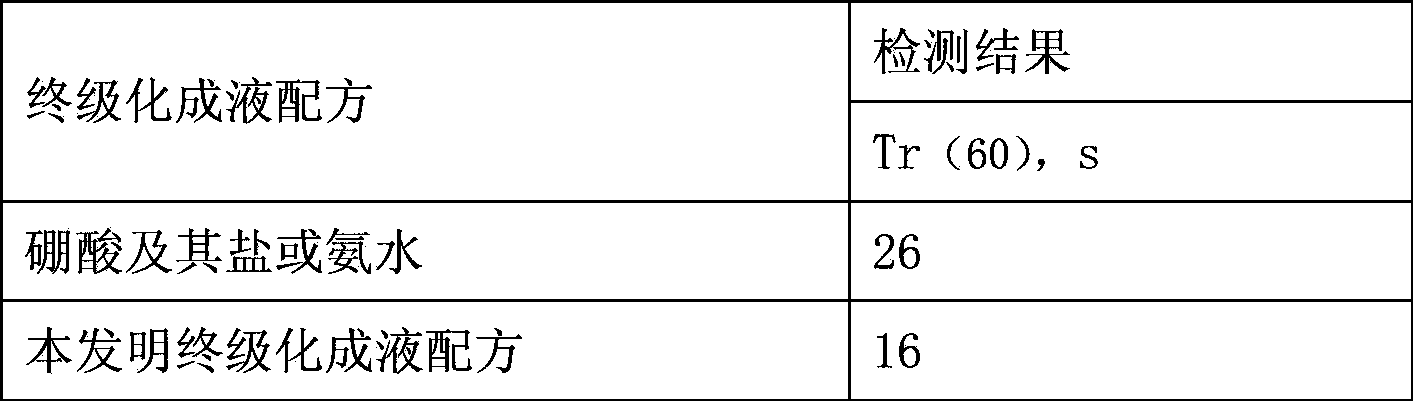

[0024] table 3

[0025]

[0026] From the experimental results in Table 3, it can be seen that the boosting time Tr(60) after the hydration resistance of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com