Depolarization method in foiling process of electronic aluminum foil

A technology of electronic aluminum foil and processing method, which is applied in the direction of circuits, capacitors, electrolytic coatings, etc., can solve the problems of poor leakage current performance, long boosting time of formed foil, etc., and achieve the effect of less equipment investment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

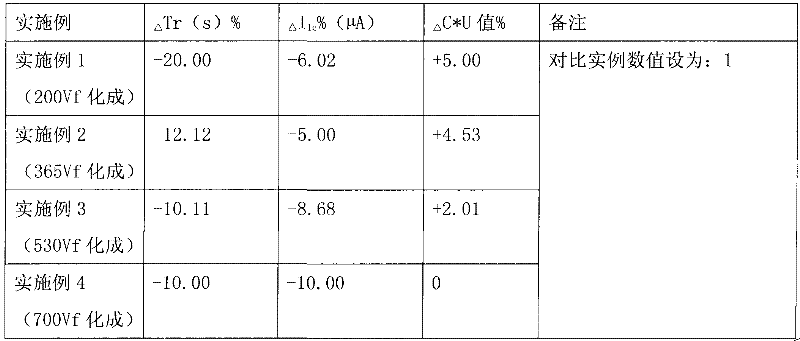

Examples

Embodiment 1

[0024] This embodiment is 200Vf formation. A depolarization treatment method in the process of forming an electronic aluminum foil into a foil, comprising the following steps:

[0025] Step 1: Boil in pure water above 97°C for 5 minutes with medium and high pressure corrosion foil with a purity of 99.99% or more;

[0026] Step 2: Formation 1, 10min;

[0027] Step 3: Perform depolarization treatment in high-temperature pure water at 70°C for 3 minutes;

[0028] Step 4: Form into 2, 10min;

[0029] Step 5: Perform depolarization treatment in high-temperature pure water at 70°C for 3 minutes;

[0030] Step 6: Formation 3, 20min;

[0031] Step 7: Perform depolarization treatment in high-temperature pure water at 70°C for 3 minutes;

[0032] Then heat treatment; re-formation; phosphoric acid treatment; re-formation.

Embodiment 2

[0034] This embodiment is 365Vf chemical formation. A depolarization treatment method in the process of forming an electronic aluminum foil into a foil, comprising the following steps:

[0035] Step 1: Boil in pure water above 97°C for 5 minutes with medium and high pressure corrosion foil with a purity of 99.99% or more;

[0036] Step 2: Formation 1, 15min;

[0037] Step 3: Perform depolarization treatment in high-temperature pure water at 60°C for 3 minutes;

[0038] Step 4: Form into 2, 15min;

[0039] Step 5: Perform depolarization treatment in high-temperature pure water at 80°C for 3 minutes;

[0040] Step 6: Formation 3, 30min;

[0041] Step 7: Perform depolarization treatment in high-temperature pure water at 70°C for 3 minutes;

[0042] Then heat treatment; re-formation; phosphoric acid treatment; re-formation.

Embodiment 3

[0044] This embodiment is 530Vf formation. A depolarization treatment method in the process of forming an electronic aluminum foil into a foil, comprising the following steps:

[0045] Step 1: Boil in pure water above 97°C for 8 minutes with medium and high pressure corrosion foil with a purity of 99.99% or more;

[0046] Step 2: Formation 1, 15min;

[0047] Step 3: Perform depolarization treatment in high-temperature pure water at 80°C for 4 minutes;

[0048] Step 4: Form into 2, 15min;

[0049] Step 5: Perform depolarization treatment in high-temperature pure water at 60°C for 4 minutes;

[0050] Step 6: Formation 3, 30min;

[0051] Step 7: Perform depolarization treatment in high-temperature pure water at 90°C for 4 minutes;

[0052] Then heat treatment; re-formation; phosphoric acid treatment; re-formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com