Large-hole-pitch anodized aluminum oxide film based on parabolic equation boosting and preparation method and application of large-hole-pitch anodized aluminum oxide film

An anodized aluminum oxide and anodic oxidation technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of undetermined boosting time, unfavorable anodized aluminum oxide film, uneven reaction rate, etc., to achieve Avoid ablation phenomenon, strong flexibility and adaptability, clear effect of boost time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Place 5cm×2cm aluminum foil successively in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 15 minutes each to remove the oil stains adhering to the surface; then soak the cleaned aluminum foil in 1mol / L sodium hydroxide solution Etched for 5min.

[0036] Step II, the clean aluminum foil treated in step I is used as the anode, and the graphite sheet is used as the cathode, and placed in a polishing solution (a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5), at 0°C and a constant voltage of 20V , polished for 5 minutes, and finally rinsed with deionized water to obtain an aluminum foil with a smooth mirror surface.

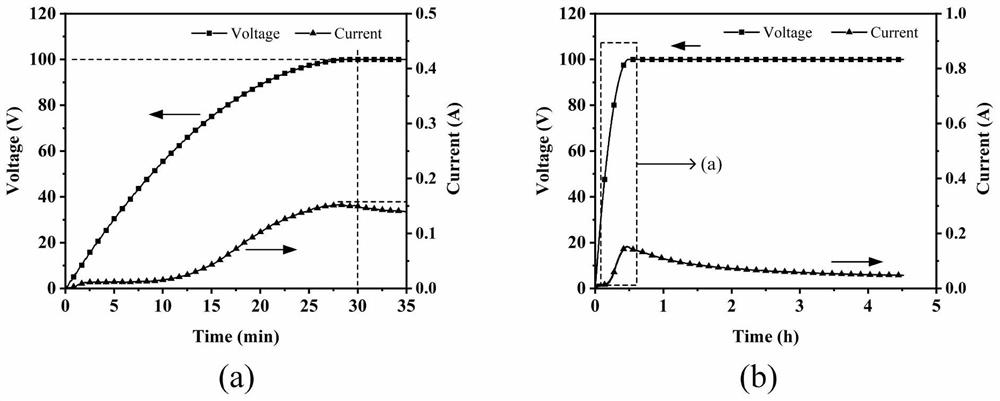

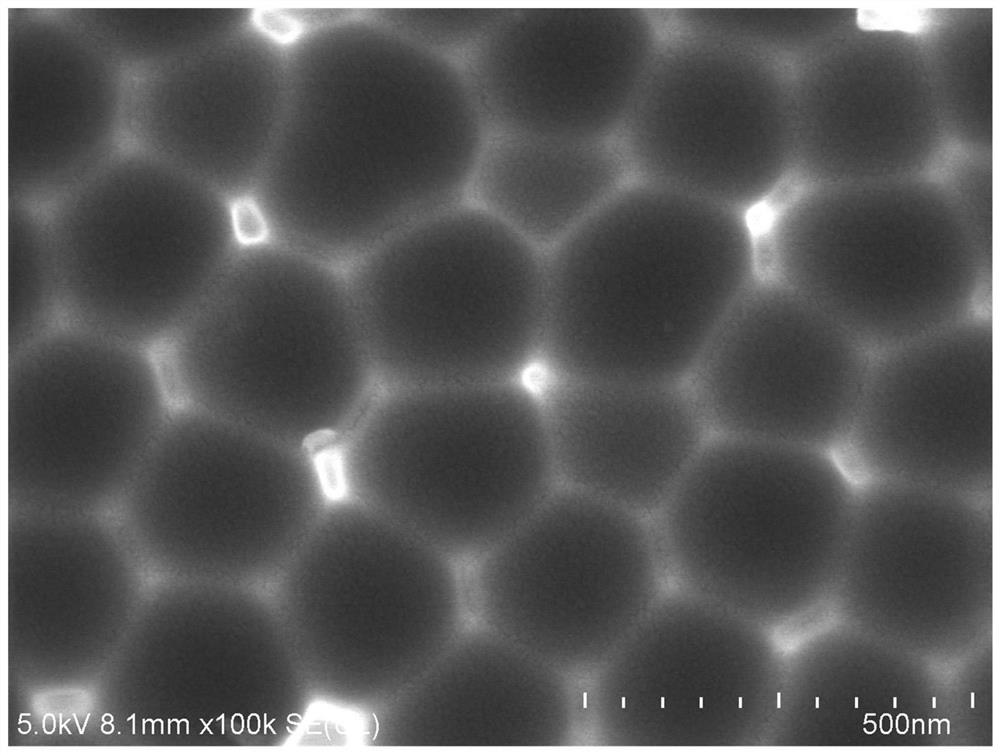

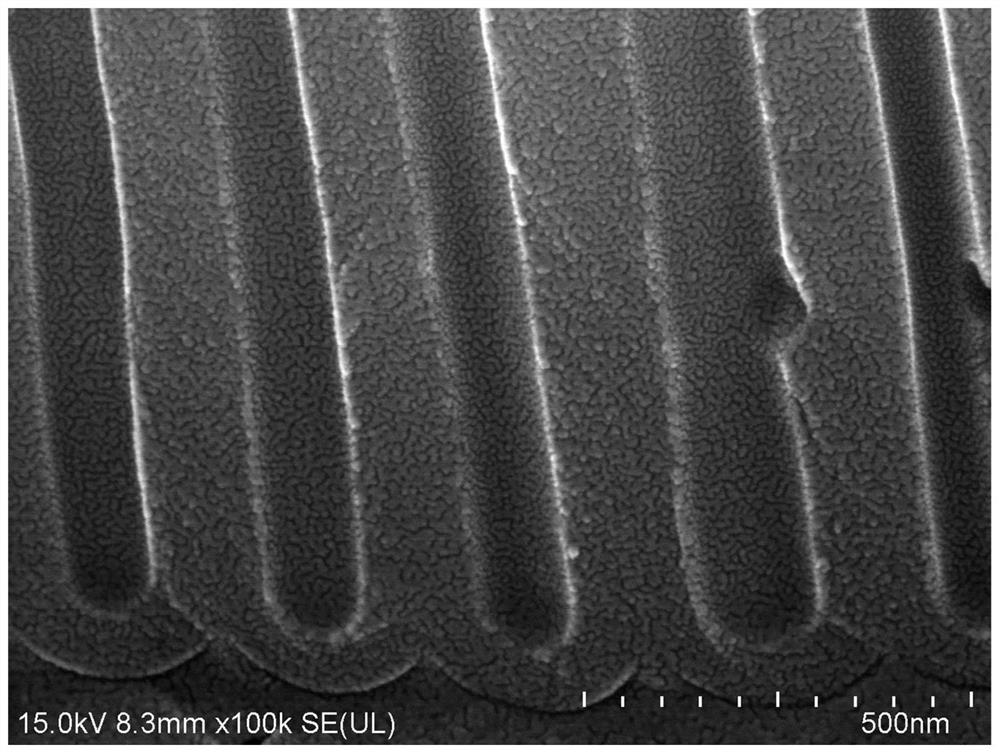

[0037]Step III, the specular aluminum foil obtained through step II is used as an anode, and the graphite sheet is a cathode, and a mixed solution of 0.3mol / L oxalic acid and ethanol (the volume ratio of oxalic acid and ethanol is 1:1) is used as an electrolyte, and the temperature of the solution ...

Embodiment 2

[0042] Step 1. Place 5cm×5cm aluminum foil successively in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 15 minutes each to remove the oil stains adhering to the surface; then soak the cleaned aluminum foil in 1mol / L sodium hydroxide solution Etched for 5min.

[0043] Step II, the clean aluminum foil treated in step I is used as the anode, and the graphite sheet is used as the cathode, and placed in a polishing solution (a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5), at 0°C and a constant voltage of 20V , polished for 5 minutes, and finally rinsed with deionized water to obtain an aluminum foil with a smooth mirror surface.

[0044] Step III, the mirror surface aluminum foil obtained through step II is used as the anode, the graphite sheet is the cathode, and the mixed solution of 0.3mol / L oxalic acid solution and ethanol (the volume ratio of oxalic acid and ethanol is 1:1) is used as the electrolyte, and the temperatur...

Embodiment 3

[0047] Step 1. Place 5cm×5cm aluminum foil successively in deionized water, acetone and absolute ethanol for ultrasonic cleaning for 15 minutes each to remove the oil stains adhering to the surface; then soak the cleaned aluminum foil in 1mol / L sodium hydroxide solution Etched for 5min.

[0048] Step II, the clean aluminum foil treated in step I is used as the anode, and the graphite sheet is used as the cathode, and placed in a polishing solution (a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5), at 0°C and a constant voltage of 20V , polished for 5 minutes, and finally rinsed with deionized water to obtain an aluminum foil with a smooth mirror surface.

[0049] Step III, the mirror-faced aluminum foil obtained through step II is used as the anode, the graphite sheet is the cathode, and the mixed solution of 0.3mol / L oxalic acid solution and ethanol (the volume ratio of oxalic acid and ethanol is 1:2) is used as the electrolyte, and the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com