High back pressure igniting method of gasification furnace

A high back pressure, gasifier technology, applied in the field of gasifiers, can solve the problems of increased system start-up time, increased production costs, increased oxygen and fuel gas loss, etc., to shorten the boosting time, improve production efficiency, high The effect on success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

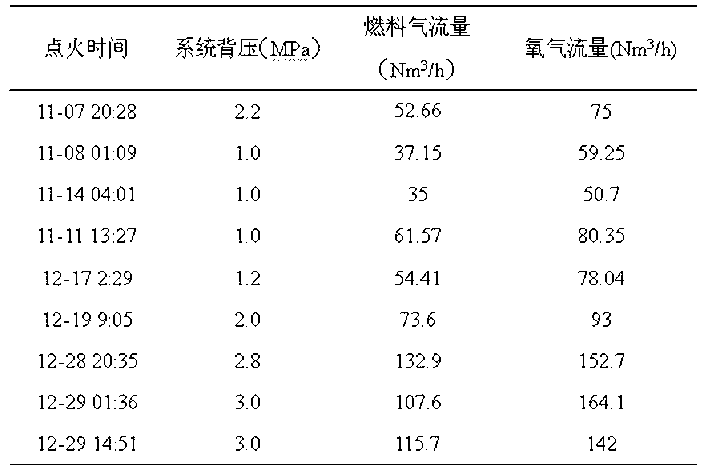

[0016] Embodiment 1 of the present invention: high back pressure ignition method of gasifier, ignition is carried out on the Kaiyang furnace of Kaiyang Chemical Factory, the ignition time is 20:28 on November 7, 2012, and the ignition back pressure is 2.2MPa , the gas flow rate is 52.66Nm 3 / h, the oxygen flow rate is 75Nm 3 / h, using a high-energy igniter with a power of 20J for ignition.

Embodiment 2

[0017] Embodiment 2 of the present invention: high back pressure ignition method of gasifier, ignition is carried out on the Kaiyang furnace of Kaiyang Chemical Factory, the ignition time is 04:01 on November 14, 2012, and the ignition back pressure is 1.0MPa , the gas flow rate is 35Nm 3 / h, the oxygen flow rate is 50.7Nm 3 / h, using a high-energy igniter with a power of 20J for ignition.

Embodiment 3

[0018] Embodiment 3 of the present invention: high back pressure ignition method of gasifier, ignition is carried out on the Kaiyang furnace of Kaiyang Chemical Factory, the ignition time is 2:29 on December 17, 2012, and the ignition back pressure is 1.2MPa , the gas flow rate is 54.41Nm 3 / h, the oxygen flow rate is 78.04Nm 3 / h, using a high-energy igniter with a power of 20J for ignition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com