Manufacturing method of oil-way hole in base space and locating tool of oil-way hole

A technology for positioning tooling and oil passage holes, which is applied to positioning devices, manufacturing tools, metal processing equipment, etc., and can solve problems such as difficulty in guaranteeing processing quality, intersection and dislocation of deep oil passage holes on the side of the positioning reference, and small holes on the bottom surface, affecting quality, etc. , to achieve the effects of improving production efficiency, avoiding cumulative positioning errors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

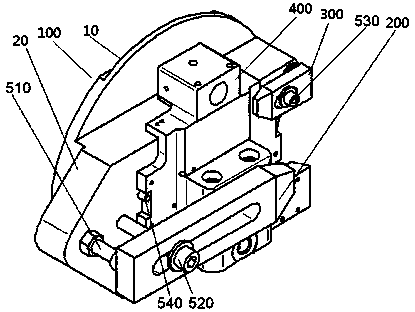

[0031] like Figure 1-Figure 3 As shown, a positioning tool for manufacturing oil passage holes in the base space, the tooling includes: a base 100; a pressure plate 200 arranged on the end surface of the workpiece 400 to be processed and connected to the base 100; arranged on the end surface of the workpiece 400 to be processed, and The compression fixing block 300 connected with the base 100 .

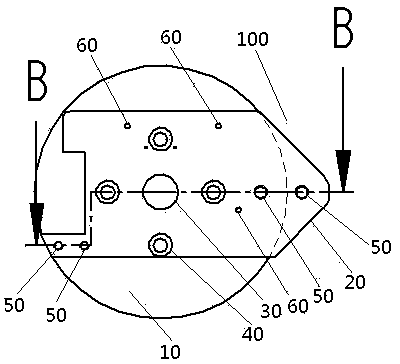

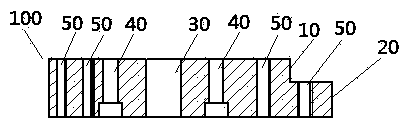

[0032] The base 100 includes: a circular chassis 10 ; The base 100 is provided with a tooling center hole 30 , and the tooling center hole 30 is set at the center of the chassis 10 and communicates with the mounting bracket 20 .

[0033] One end of the mounting bracket 20 is triangular, and the other end is "concave". The triangular end of the mounting bracket 20 extends outside the chassis 10 , and the “concave” end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com