Cleaning method of electronic energy storage materials

An energy storage material and electronic technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problem of ineffective reduction of aluminum powder on the surface of corroded foil and particle powder impurities in the cavity, unstable riveting of front and rear rolls, and shortening of foil boost Time and other issues, to achieve the effect of shortening mechanical properties, reducing foil breakage, and improving electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

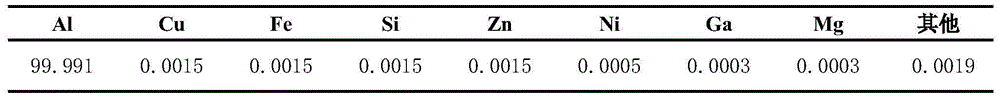

[0027] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 550°C for 1 hour as the raw material, the cubic texture is ≧96%, and the thickness is 116 μm; the chemical composition of the raw material aluminum foil is shown in Table 1.

[0028] The chemical composition of table 1 raw material aluminum foil (mass fraction, %)

[0029]

[0030] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0031] (1) Pretreatment: first soak the raw material aluminum foil in a 0.7mol / L sodium hydroxide solution at a temperature of 50°C for 100s, and then place it in a mixed solution containing 5wt% hydrochloric acid and 0.8wt% oxalic acid at a temperature of 70°C Soak for 100s, and finally wash with pure water;

[0032] (2) Electrochemical porosity corrosion: place the pretreated aluminum foil in a mixed solution containing 22wt% sulfuric acid, 4wt% nitric acid and 0.9wt% aluminum ions ...

Embodiment 2

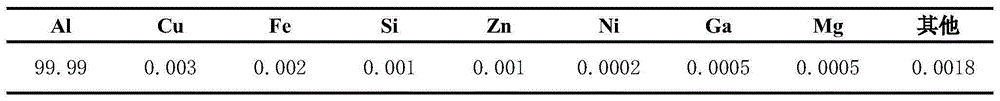

[0040] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 530°C for 1.5h as the raw material, the cubic texture is ≧95%, and the thickness is 110 μm; the chemical composition of the raw material aluminum foil is shown in Table 2.

[0041] The chemical composition of table 2 raw material aluminum foil (mass fraction, %)

[0042]

[0043] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0044] (1) Pretreatment: first soak the raw material aluminum foil in a 0.8mol / L sodium hydroxide solution at a temperature of 60°C for 50s, and then place it in a mixed solution containing 6wt% hydrochloric acid and 1.5wt% oxalic acid at a temperature of 60°C Soak for 150s, and finally wash with pure water;

[0045] (2) Electrochemical porosity corrosion: place the pretreated aluminum foil in a mixed solution containing 30wt% sulfuric acid, 6wt% nitric acid and 1.2wt% aluminum ions for...

Embodiment 3

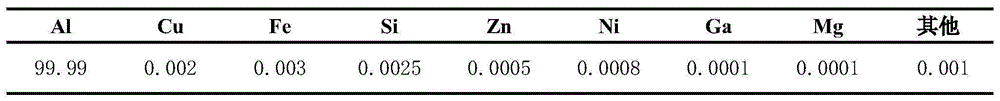

[0053] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 580°C for 0.5h as the raw material, with a cubic texture ≥ 95% and a thickness of 120 μm; the chemical composition of the raw material aluminum foil is shown in Table 3.

[0054] The chemical composition of table 3 raw material aluminum foil (mass fraction, %)

[0055]

[0056] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0057] (1) Pre-treatment: First soak the raw material aluminum foil in a 0.6mol / L sodium hydroxide solution at a temperature of 40°C for 150s, and then soak it in a mixed solution containing 2wt% hydrochloric acid and 1wt% oxalic acid at a temperature of 80°C 50s, and finally wash with pure water;

[0058] (2) Electrochemical porosity corrosion: place the pretreated aluminum foil in a mixed solution containing 15wt% sulfuric acid, 6wt% nitric acid and 0.6wt% aluminum ions for direct curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com