IC (Integrated Circuit) plastic-package body voltage withstand test clamp and test methods

A technology of withstand voltage test and withstand voltage tester, which is applied in the direction of testing dielectric strength and measuring device casing, etc., which can solve problems such as long cycle time and affecting test production capacity, and achieve the goal of improving production efficiency, increasing test capacity and improving test efficiency Effect

Inactive Publication Date: 2012-11-28

HANGZHOU SILAN INTEGRATED CIRCUIT

View PDF11 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the withstand voltage test is for a single IC product, and a single IC product needs to be subjected to a withstand voltage test one by one. However, since the withstand voltage test requires a certain boost time, the cycle required to test an IC product is relatively long , so, seriously affect the test capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0072] This IC plastic package withstand voltage test method includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

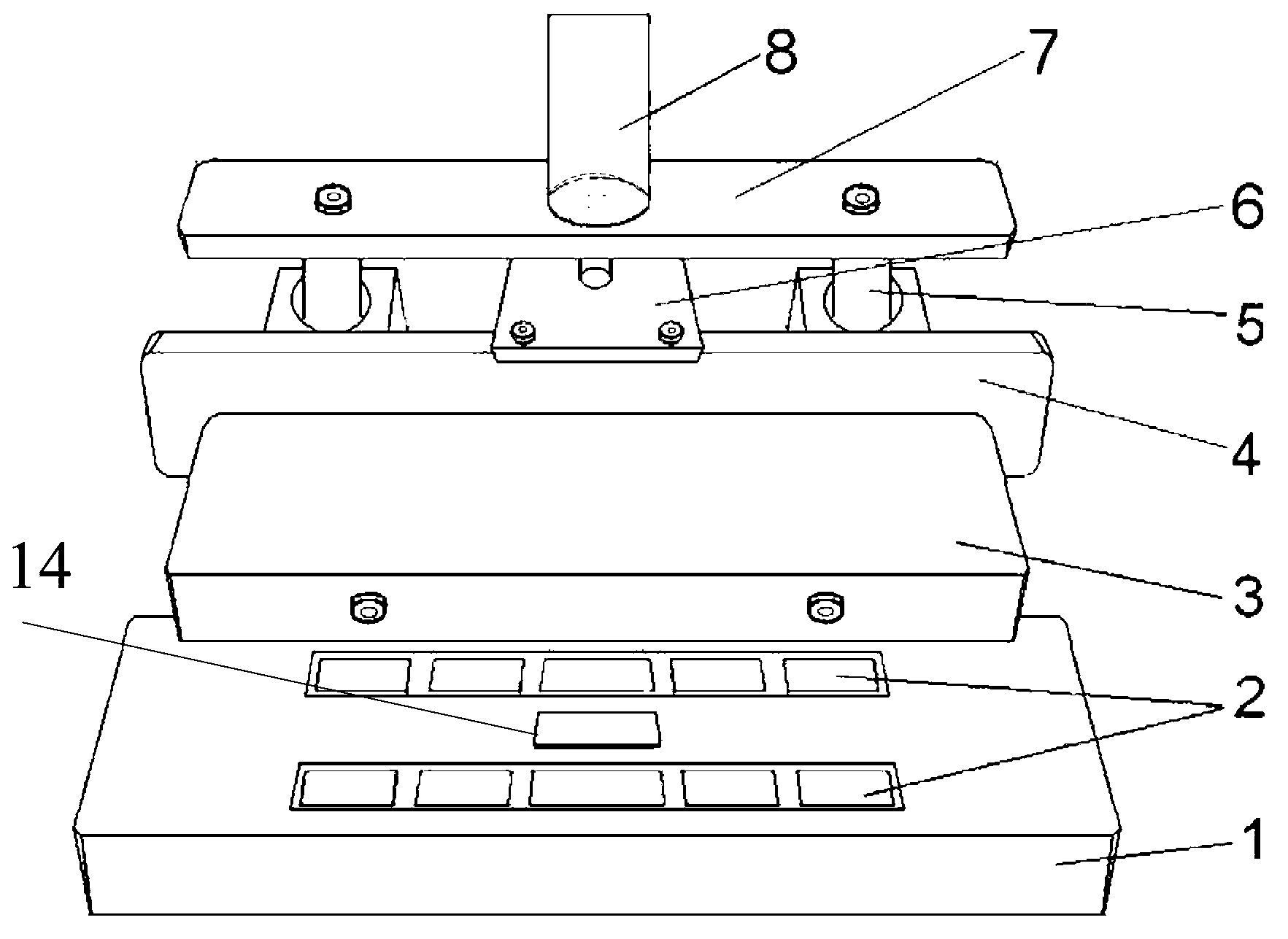

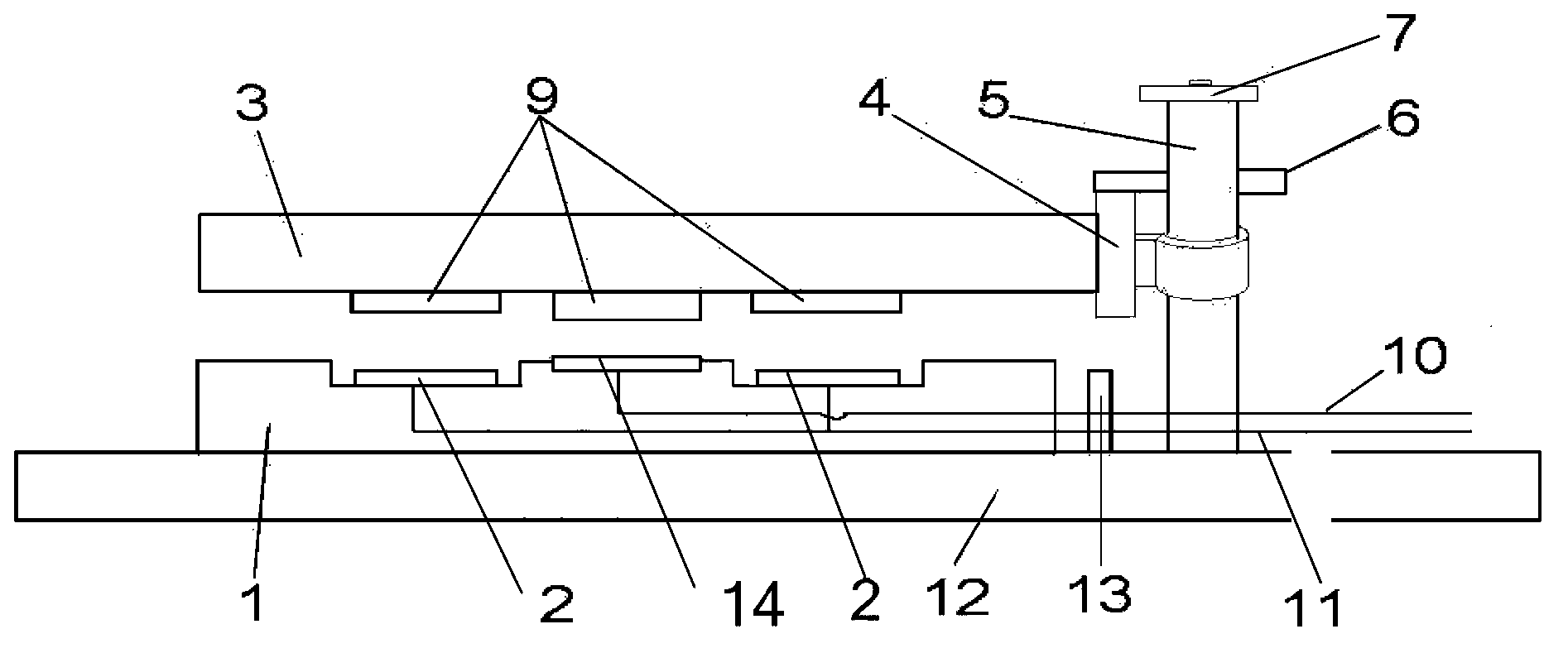

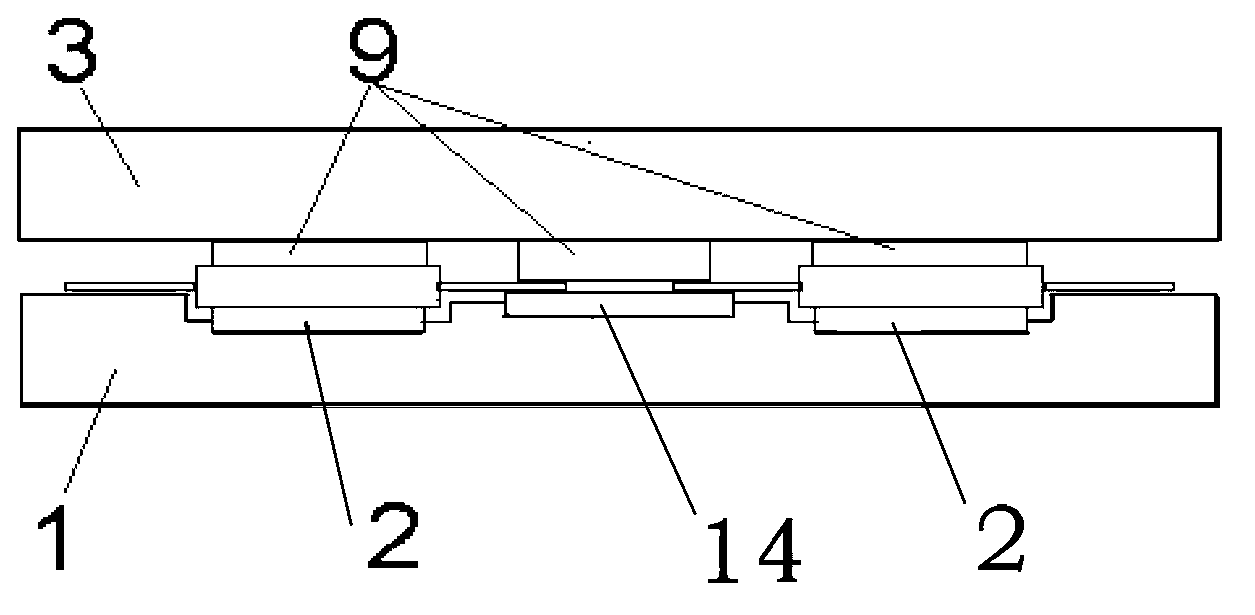

The invention discloses an IC (Integrated Circuit) plastic-package body voltage withstand test clamp which comprises a fixed base, a pressing plate and a guide pillar, wherein at least one bearing body which is used for placing a whole IC plastic-package body is arranged on the fixed base; the bearing body is internally provided with a plurality of first metal gaskets which are arranged at intervals and electrically connected with the cathode of a voltage withstand tester; a second metal gasket which is connected with the anode of the voltage withstand tester is also arranged on the fixed base; and the pressing plate is arranged on the guide pillar and is capable of moving up and down relative to the guide pillar. The invention discloses two plastic-package body voltage withstand test methods. According to the clamp and the methods, a voltage withstand test can be carried out on the whole IC plastic-package body before products are subjected to trimming and forming, so that the test efficiency is improved and the voltage withstand test can be carried out on a plurality of IC plastic-package bodies at the same time.

Description

technical field [0001] The invention relates to the field of semiconductor manufacturing, in particular to a jig and a test method for withstand voltage testing of an IC plastic package. Background technique [0002] At present, in the electronic component manufacturing industry, the existing withstand voltage test scheme: first cut and shape the entire IC plastic package to form a single IC product; then perform the withstand voltage test. The withstand voltage test is to test whether the plastic-encapsulated product can withstand the required voltage. Among them, IC stands for Integrated Circuit, the meaning of integrated circuit. [0003] It can be seen that the withstand voltage test of the existing IC plastic package is arranged in the final test process, and the withstand voltage test of a single IC product is carried out. However, the withstand voltage test is for a single IC product, and a single IC product needs to be subjected to a withstand voltage test one by o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R1/04G01R31/12

Inventor 王加平

Owner HANGZHOU SILAN INTEGRATED CIRCUIT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com