Processing method of electrode foil used for aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and processing methods, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of accelerated chemical dissolution of oxide film, long boosting time, and large leakage current, so as to improve the formation efficiency and shorten the boosting time , The effect of reducing the leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

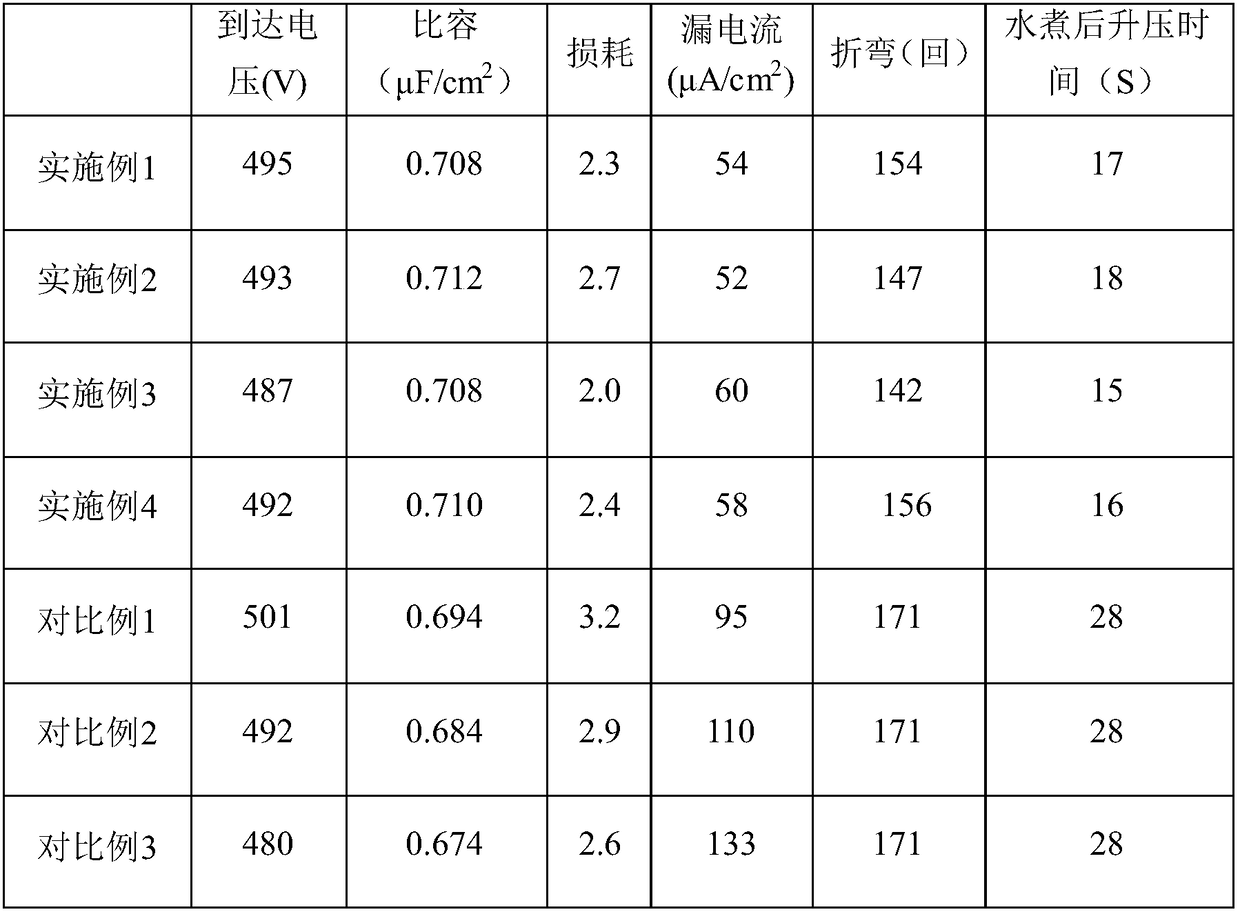

[0024] Constant current boost (10A / cm 2 ) → positive constant voltage (150V, 10S) → stop (1S) → negative constant voltage (150V, 2S) → stop (1S) → ... cycle 10 times → positive constant voltage (300V, 10S) → stop ( 1S)→Negative constant voltage (300V, 2S)→Stop (1S)→…cycle 10 times→Positive constant voltage (450V, 10S)→Stop (1S)→Negative constant voltage (450V, 2S)→Stop (1S)→...cycle 10 times→positive constant voltage (500V, 10S)→stop (1S)→negative constant voltage (500V,2S)→stop (1S)→...cycle 10 times→burning (2min )→500V supplementary formation (positive constant voltage 10S, stop 1S, negative constant voltage 2S, cycle 10 times). The test results are shown in Table 1.

Embodiment 2

[0026] Constant current boost (80A / cm 2 )→Positive constant voltage (150V, 20S)→Stop (1S)→Negative constant voltage (150V, 2S)→Stop (1S)→...cycle 15 times→Positive constant voltage (300V, 20S)→Stop ( 1S)→Negative Constant Voltage (300V, 2S)→Stop (1S)→...Cycle 15 times→Positive Constant Voltage (450V, 20S)→Stop (1S)→Negative Constant Voltage (450V, 2S)→Stop (1S)→...cycle 15 times→positive constant voltage (500V, 20S)→stop (1S)→negative constant voltage (500V,2S)→stop (1S)→...cycle 15 times→burning (2min )→500V supplementary formation (positive constant voltage 20S, stop 1S, negative constant voltage 2S cycle 15 times). The test results are shown in Table 1.

Embodiment 3

[0028] Constant current boost (60A / cm 2 ) → positive constant voltage (150V, 20S) → stop (1S) → negative constant voltage (150V, 1S) → stop (1S) → ... cycle 10 times → positive constant voltage (300V, 20S) → stop ( 1S)→negative constant voltage (300V, 1S)→stop (1S)→…cycle 10 times→positive constant voltage (450V,20S)→stop (1S)→negative constant voltage (450V,1S)→stop (1S)→...cycle 10 times→positive constant voltage (500V, 20S)→stop (1S)→negative constant voltage (500V,1S)→stop (1S)→...cycle 10 times→burning (2min )→500V supplementary formation (positive constant voltage 20S, stop 1S, negative constant voltage 1S cycle 10 times). The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com