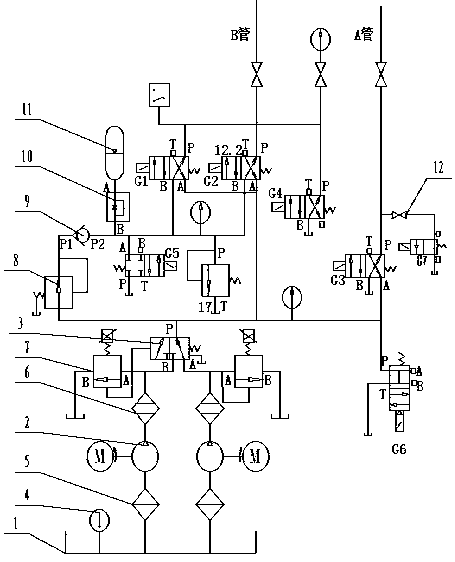

Elevator braking system redundancy loop

A brake system and hoist technology, applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problem that the oil in the brake cannot be quickly returned to the mailbox, the spool of the reversing valve is stuck, and the cost of replacing the hydraulic station High-level problems, to achieve the effect of meeting the requirements of regulations, small construction volume, and short lifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] A redundant circuit of the braking system of a hoist, including two hydraulic stations, the hydraulic station includes a fuel tank 1, an oil pump 2 connected to the fuel tank, and the two hydraulic stations are connected to pipe A and B pipe, said B pipe includes redundant solenoid valve G1 and redundant solenoid valve G2 connected with hydraulic reversing valve 3, said redundant solenoid valve G1 and redundant solenoid valve G2 are connected in parallel, redundant solenoid valve G1 and redundant solenoid valve The input end of the redundant electromagnetic valve G2 is connected to the output end of the hydraulic reversing valve 3, the output ends of the redundant electromagnetic valve G1 and the redundant electromagnetic valve G2 are connected to the working cylinder, and the b pipe also includes b for safety braking. The electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com