High-capacity low-loss medium-voltage anode foil and formation process thereof

A low-loss, anode foil technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of unguaranteed quality consistency, complicated production line control and liquid dispensing, and unfavorable production line stability control, and achieve good product consistency and loss. The effect of small, short boost time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

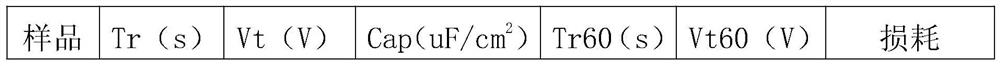

Embodiment 1

[0099] The specific operation steps are as follows:

[0100] (1) Pretreatment: Treat the corroded aluminum foil with a purity of 99.99% in pure water at a temperature of 90-98°C for 3-10 minutes;

[0101] (2) Primary formation: the pretreated aluminum foil is charged in the first stage in an aqueous solution containing 0.1-1.5wt% boric acid, 0.1-1wt% phosphoric acid and phosphate, 0.1-1wt% citric acid and citrate Treatment, temperature 80-95°C, current density 25-55mA / cm 2 , the applied voltage is 30-35% vf, and the formation time is 3-10min;

[0102] (3) Secondary formation: the aluminum foil after primary formation is subjected to second-stage addition in an aqueous solution containing 0.2-2wt% boric acid, 0.1-1wt% phosphoric acid and phosphate, 0.1-1wt% citric acid and citrate Electric treatment, temperature 80-95°C, current density 25-55mA / cm 2 , the applied voltage is 60-70% vf, and the formation time is 3-10min;

[0103](4) Tertiary formation: the aluminum foil after...

Embodiment 2

[0117] The specific operation steps are as follows:

[0118] (1) Pretreatment: Treat the corroded aluminum foil with a purity of 99.99% in pure water at a temperature of 95°C for 6 minutes;

[0119] (2) One-stage formation: the pre-treated aluminum foil is subjected to the first-stage electrification treatment in an aqueous solution containing 0.8wt% boric acid, 0.5wt% phosphoric acid and phosphate, 0.5wt% citric acid and citrate, and the temperature is 85 ℃, current density 50mA / cm 2 , the applied voltage is 32% vf, and the formation time is 3 minutes;

[0120] (3) Secondary formation: the aluminum foil after the first-level formation is subjected to the second-stage electrification treatment in an aqueous solution containing 1.2wt% boric acid, 0.4wt% phosphoric acid and phosphate, 0.4wt% citric acid and citrate, Temperature 85℃, current density 40mA / cm 2 , the applied voltage is 65% vf, and the formation time is 3 minutes;

[0121] (4) Tertiary formation: the aluminum fo...

Embodiment 3

[0150] The specific operation steps are as follows:

[0151] (1) Pretreatment: Treat the corroded aluminum foil with a purity of 99.99% in pure water at a temperature of 95°C for 10 minutes;

[0152] (2) Primary formation: The pretreated aluminum foil is subjected to the first-stage electrical treatment in an aqueous solution containing 0.8wt% boric acid, 0.4wt% ammonium dihydrogen phosphate, 0.4wt% citric acid and citrate, at a temperature of 85 ℃, current density 50mA / cm 2 , the applied voltage is 32% vf, and the formation time is 5 minutes;

[0153](3) Secondary formation: the aluminum foil after the first-level formation is subjected to the second-stage electrification treatment in an aqueous solution containing 1.2wt% boric acid, 0.3wt% ammonium dihydrogen phosphate, 0.3wt% citric acid and citrate, Temperature 85℃, current density 40mA / cm 2 , the applied voltage is 65% vf, and the formation time is 5 minutes;

[0154] (4) Tertiary formation: the aluminum foil after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com