Electrolyte for high-voltage soldering lug type aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and high-voltage welding technology, applied in the field of capacitors, can solve the problems of high loss angle, large capacity attenuation at low temperature, high failure rate, etc. Reduce the effect of capacity fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

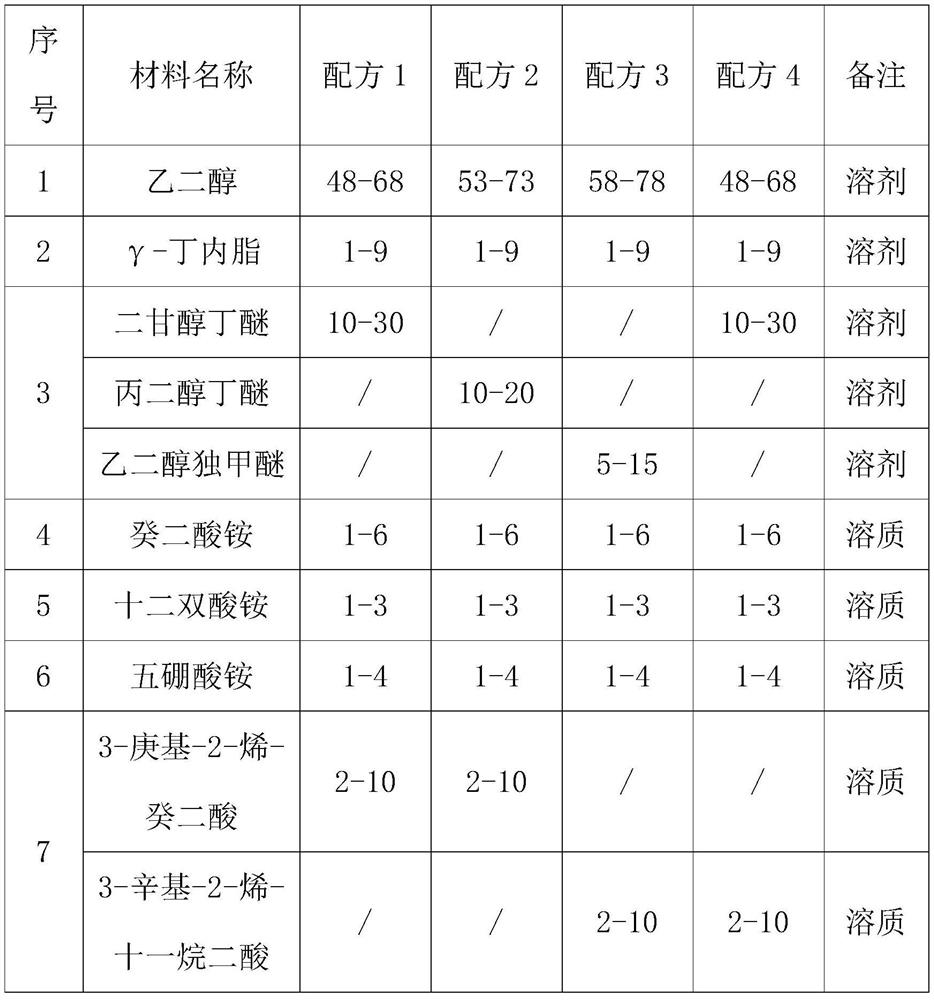

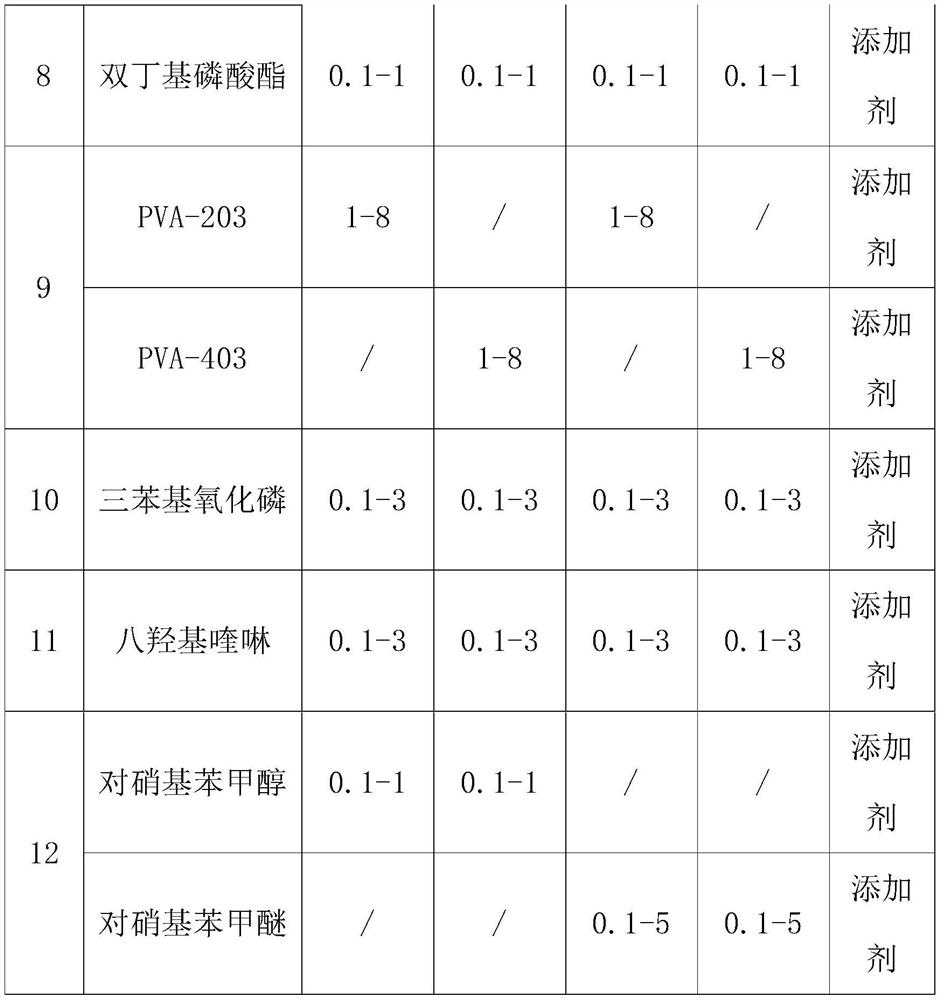

[0083] The present invention provides an electrolyte for a high-voltage solder chip aluminum electrolytic capacitor, which comprises the following components by mass percentage:

[0084] 48~78% ethylene glycol;

[0085] 1 to 9% of γ-butyrolactone;

[0086] 5-30% of any one of diethylene glycol butyl ether, propylene glycol butyl ether and ethylene glycol monomethyl ether;

[0087] 1-6% of ammonium sebacate;

[0088] 1 to 3% of ammonium dodecanoate;

[0089] 1-4% ammonium pentaborate;

[0090] 2-10% of 3-heptyl-2-ene-decanedioic acid or 3-octyl-2-ene-undecanedioic acid;

[0091] 0.1 to 1% of dibutyl phosphate;

[0092] 1~8% PVA-203 or PVA-403;

[0093] 0.1~3% triphenylphosphorus oxide;

[0094] 0.1-3% octahydroxyquinoline;

[0095] 0.1 to 5% of p-nitrobenzyl alcohol or p-nitroanisole.

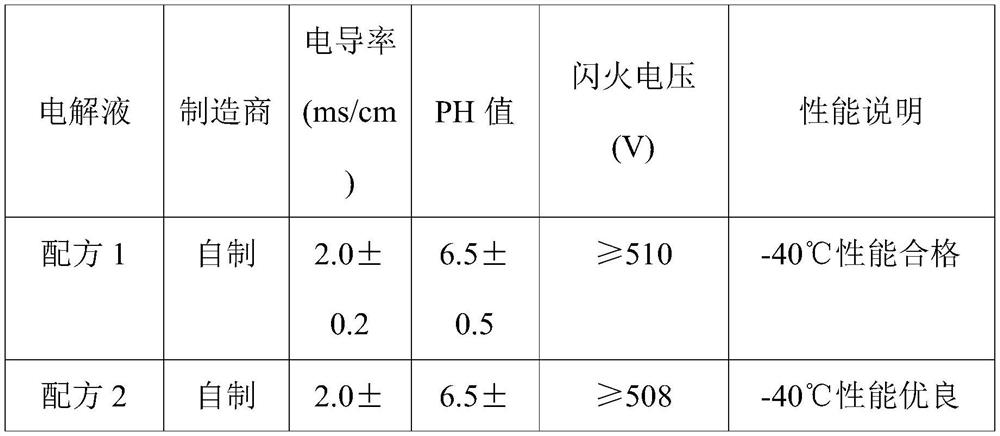

[0096] High-voltage solder chip aluminum electrolytic capacitors made from the above components have the following characteristics:

[0097] 1) Under the low temperature environment of -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com