A kind of hydrogenated nitrile rubber masterbatch and its preparation method and application

A technology for hydrogenated nitrile rubber and carboxyl nitrile rubber is applied in the field of chemical products, and can solve the problems of limited application of hydrogenated products, and achieve the effects of good stretching, cost reduction and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

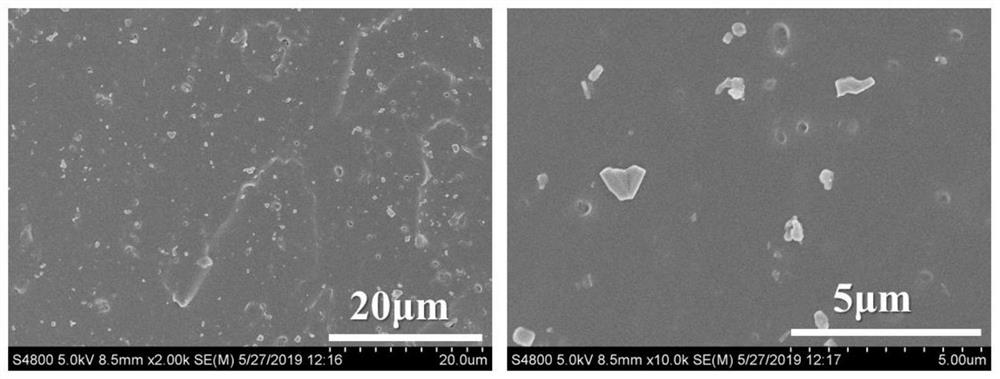

Embodiment 1

[0031]This embodiment provides a hydrogenated nitrile rubber masterbatch, and the preparation method of the hydrogenated nitrile rubber masterbatch is as follows:

[0032](1) Preparation of hydrogenated nitrile rubber emulsion: Weigh 100g of carboxylated nitrile rubber emulsion (45% by mass of carboxylated nitrile rubber, butadiene segment accounts for about 70%), and add 93.80g of hydrazine hydrate solution (mass fraction) It is 80% hydrazine hydrate); Dissolve 5.82g boric acid in 113.45g hydrogen peroxide solution (30% hydrogen peroxide by mass) and add it dropwise to the mixture of carboxyl nitrile butadiene rubber emulsion and hydrazine hydrate; React at a temperature of 50°C for 8 hours to obtain a hydrogenated nitrile rubber emulsion with a degree of hydrogenation of 95%;

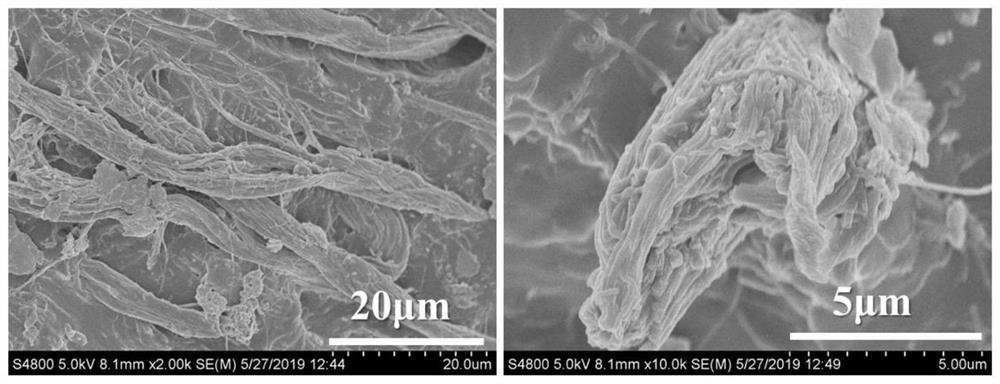

[0033](2) Digest the leather: add 10g of leather waste and 150ml of a 1.5% sodium formate aqueous solution into a 500ml three-necked round bottom flask, stir at 110°C for 5h, condense and reflux, and wash and dry...

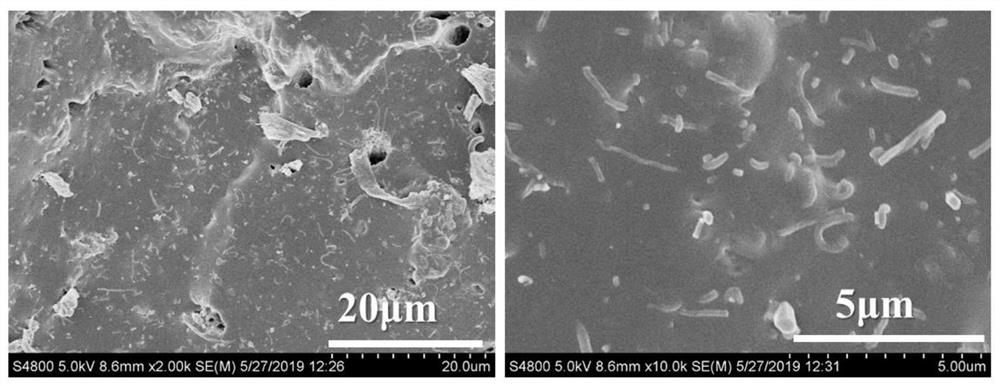

Embodiment 2

[0036]This embodiment provides a hydrogenated nitrile rubber masterbatch. The preparation method of the hydrogenated nitrile rubber masterbatch differs from Example 1 only in that 5 g of the leather prepared in step (2) is used in step (3) The fiber is placed in 100 g of the hydrogenated nitrile rubber emulsion prepared in step (1).

Embodiment 3

[0038]This embodiment provides a hydrogenated nitrile rubber masterbatch. The preparation method of the hydrogenated nitrile rubber masterbatch differs from Example 1 only in that 20g of the leather prepared in step (2) is used in step (3) The fiber is placed in 100 g of the hydrogenated nitrile rubber emulsion prepared in step (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com