A making method for thermal sediment of GaAs single-chip microwave integration circuit power amplifier

A technology of microwave integrated circuits and power amplifiers, which is applied in the manufacture of circuits, electric solid-state devices, semiconductor/solid-state devices, etc. , The effect of solving the phenomenon of bonding fracture and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

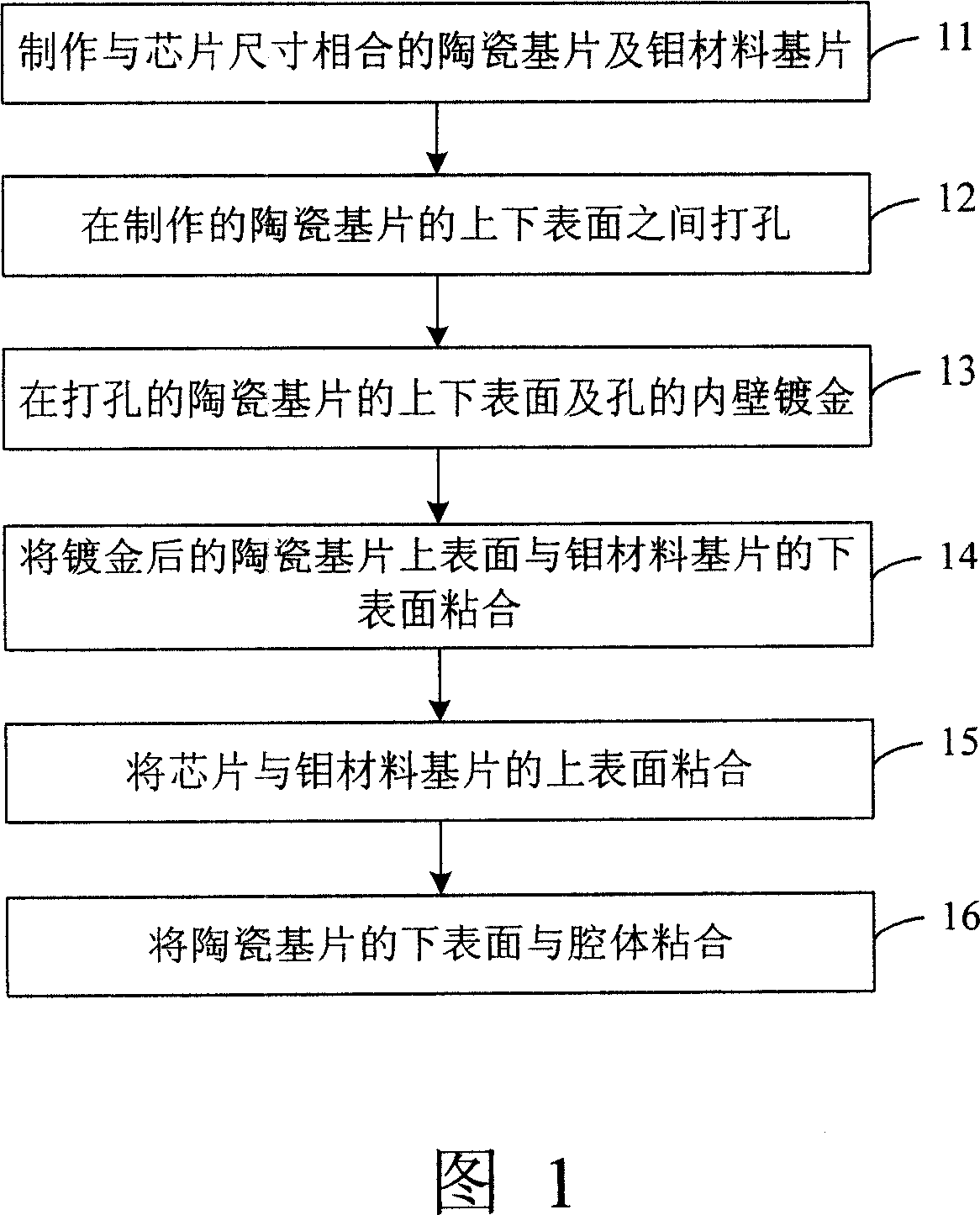

[0063] As shown in FIG. 2, FIG. 2 is a flowchart of a method for fabricating a GaAs MMIC power amplifier heat sink according to an embodiment of the present invention. The method includes the following steps:

[0064] Step 21: making a ceramic substrate with the same length and width as the chip, and making a ceramic substrate whose thickness is calculated according to the operating frequency band of the chip, and making a molybdenum material substrate with the same length, width and thickness as the chip;

[0065] The ceramic substrate is Al 2 o 3 A ceramic substrate with a content greater than or equal to 99%, or an aluminum nitride ceramic substrate; the molybdenum material substrate is a pure molybdenum material substrate;

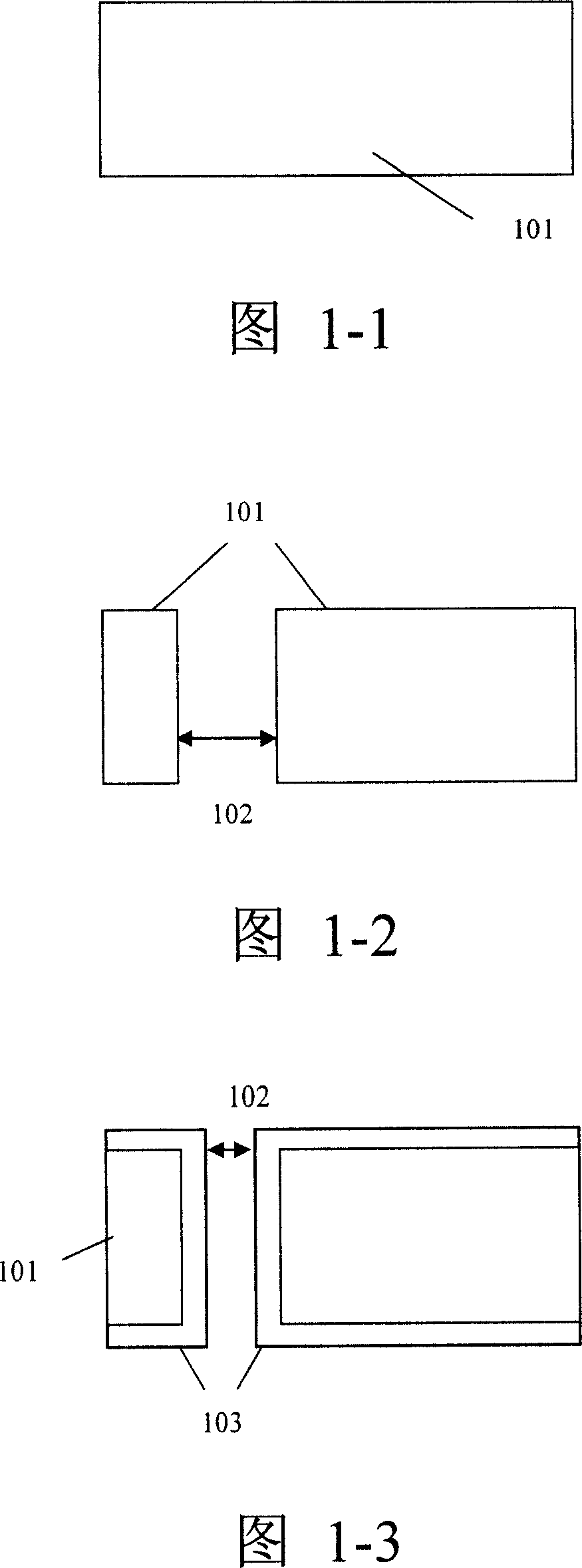

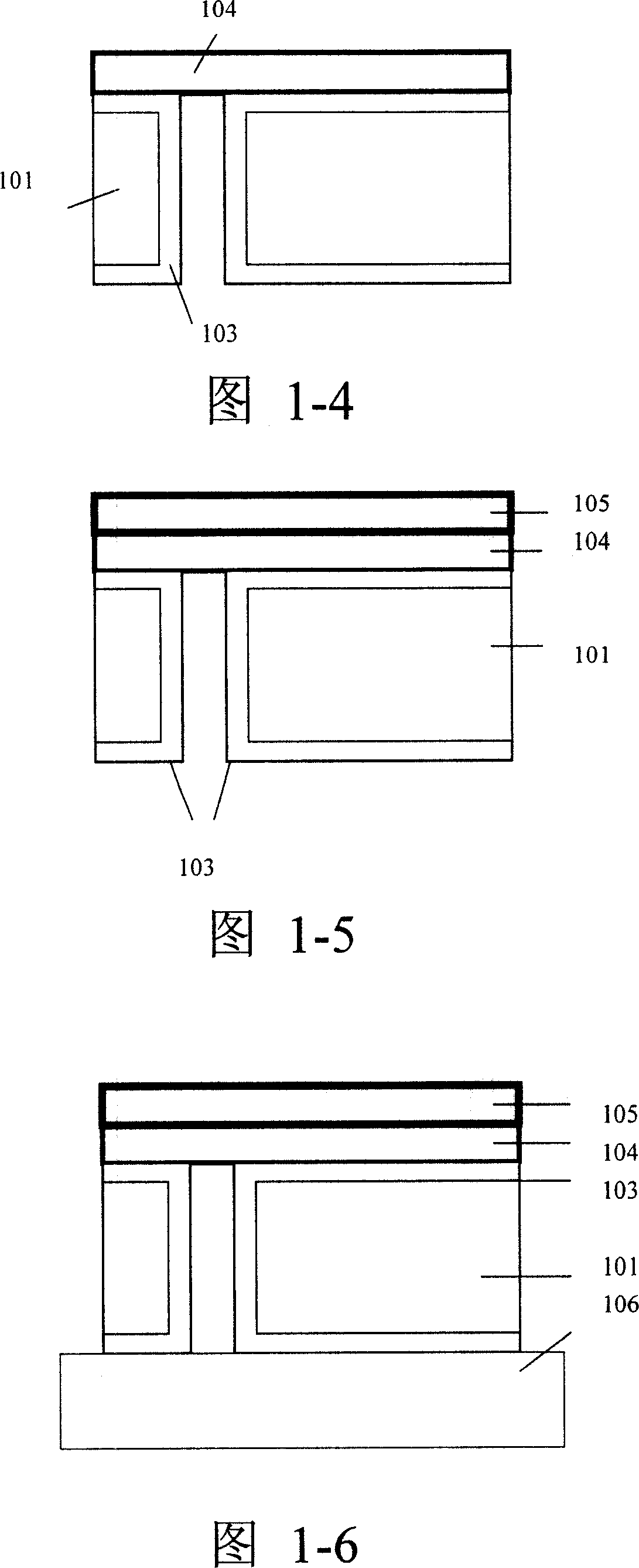

[0066] In this step, the fabricated ceramic substrate 201 is shown in FIG. 2-1 , and FIG. 2-1 is a schematic diagram of the ceramic substrate 201 fabricated according to an embodiment of the present invention.

[0067] Step 22: Drill a through hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com