A kind of refining method of di-isooctyl dodecanedioate

A technology of diisooctyl dodecanedioate and a refining method, which is applied in the preparation of carboxylate, separation/purification of carboxylate, chemical instruments and methods, etc., can solve the problem of reducing product yield, losing crude product, The acid value of the crude product is not ideally reduced, and the effect of reducing the acid value, improving the purity and yield, and shortening the standing and stratification time is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

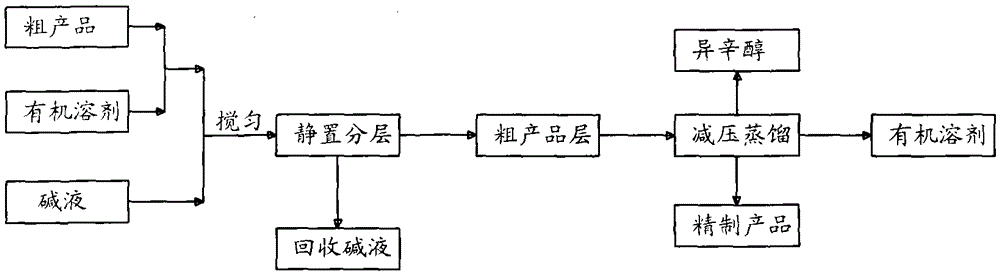

[0017] like figure 1 A specific embodiment of the refining process flow of a kind of dodecanedioic acid diisooctyl ester provided by the invention is shown, comprising the following steps:

[0018] A, with solid super acid SO 4 2- / ZrO 2 -TiO 2 As a catalyst, dodecanedioic acid and isooctyl alcohol are used to prepare a crude product of diisooctyl dodecanedioate, the acid value is 2-60 mgKOH / g, and the content is 65-85%;

[0019] B. Mix the organic solvent and the crude product from step A according to the volume ratio of (0.1-5.0): 1, and then stir with the lye solution with a mass concentration of 0.1-55.0%. Coarse product layer;

[0020] C. Under vacuum, control the temperature at 30-200° C., distill the crude product from step B under reduced pressure, remove excess isooctyl alcohol and organic solvent, and obtain high-purity diisooctyl dodecanedioate.

[0021] Preferably, the organic solvent described in step B of the present invention is any one or a combination of...

Embodiment 1

[0023] In a 250ml three-necked flask, sequentially add 50ml crude product of diisooctyl dodecanedioate, 50ml ethanol and 100ml saturated sodium bicarbonate solution, stir evenly, transfer to a 250ml separating funnel and let stand for 15min to separate the oil layer; Under negative pressure (-0.096)~(-0.099)MPa and 150℃, the crude product was distilled under reduced pressure for 30min, the acid value of the product decreased from 14.82mgKOH / g to 0.27mgKOH / g, and the ester content increased from 70.02% to 97.28% .

Embodiment 2

[0025] In a 250ml three-necked flask, sequentially add 50ml of crude diisooctyl dodecanedioate, 50ml of methanol and 50ml of sodium carbonate solution with a mass concentration of 5%, stir evenly, transfer to a 250ml separatory funnel and let stand for 20min, Separate the oil layer; under the negative pressure (-0.096)~(-0.099)MPa and 160℃, the crude product was distilled under reduced pressure for 25min, the acid value of the product decreased from 33.10mgKOH / g to 0.09mgKOH / g, and the ester content decreased from 70.67% increased to 98.35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com