Multifunctional boric acid-free electrolyte and preparation method thereof

A multi-functional, electrolyte technology, applied in the electrolyte field, can solve the problems of low ripple resistance, poor high temperature resistance, short life, etc., and achieve low large ripple resistance, wide use environment, and low saturated vapor pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

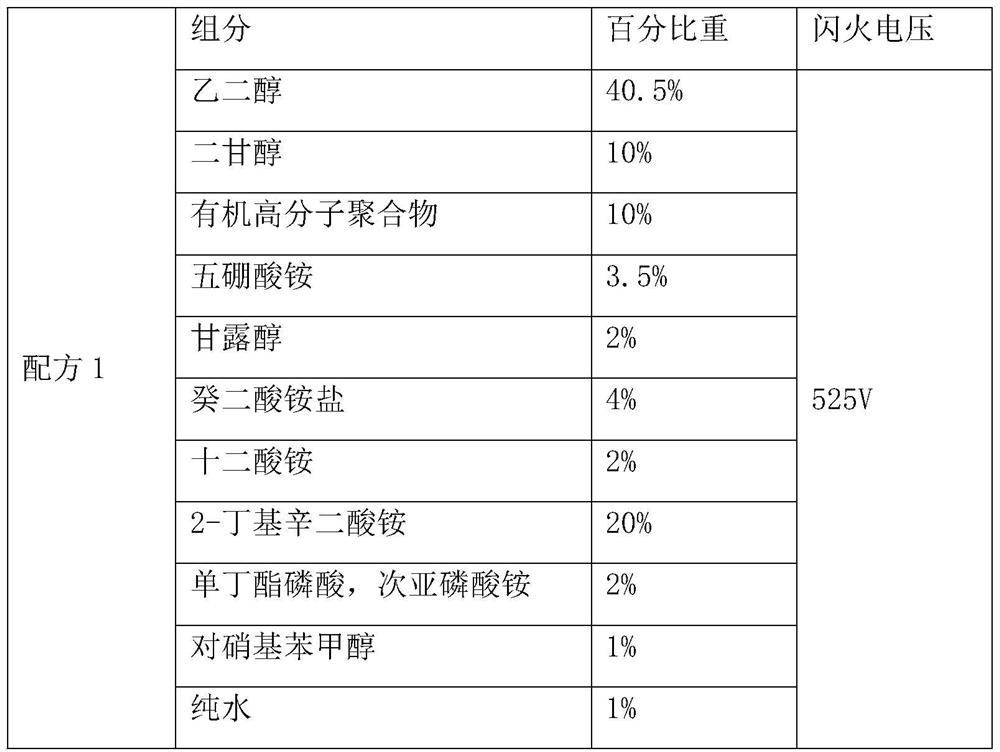

Embodiment 1

[0032]

[0033] S1: Weigh the product according to the above formula for later use; heat ethylene glycol and diethylene glycol to 135°C, then add organic high molecular polymer to dissolve completely;

[0034] S2: After the organic high molecular polymer is completely dissolved, cool down to 130°C, then add ammonium pentaborate, mannitol, ammonium sebacate, ammonium dodecanoate, and 2-butylammonium suberate, at 120°C keep warm for 1 hour;

[0035] S3: After keeping warm for 1 hour, cool down to 85°C, add monobutyl phosphoric acid, ammonium hypophosphite, p-nitrobenzyl alcohol and pure water and stir evenly;

[0036] S4: Stir evenly and cool to room temperature.

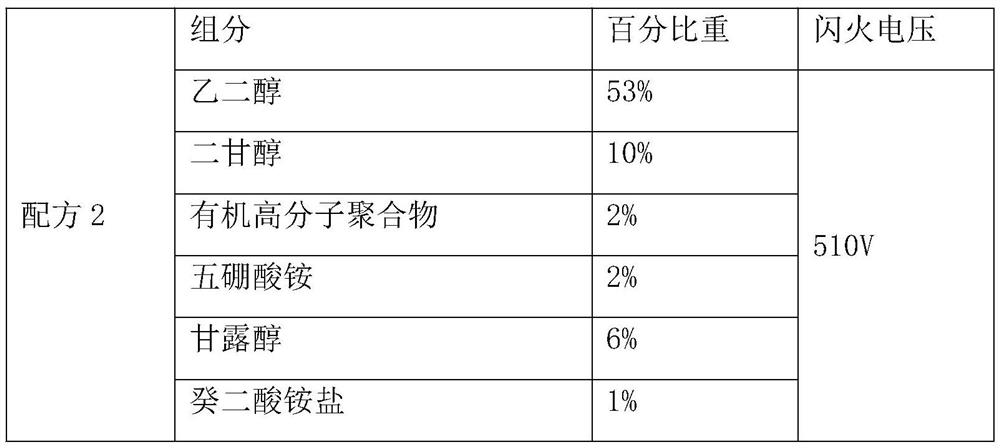

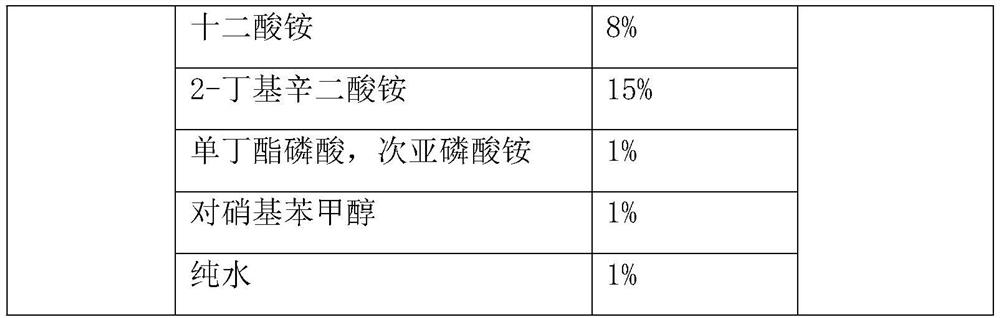

Embodiment 2

[0038]

[0039]

[0040] S1: Weigh the product according to the above formula for later use; heat ethylene glycol and diethylene glycol to 135°C, then add organic high molecular polymer to dissolve completely;

[0041] S2: After the organic high molecular polymer is completely dissolved, cool down to 130°C, then add ammonium pentaborate, mannitol, ammonium sebacate, ammonium dodecanoate, and 2-butylammonium suberate, at 120°C keep warm for 1 hour;

[0042] S3: After keeping warm for 1 hour, cool down to 85°C, add monobutyl phosphoric acid, ammonium hypophosphite, p-nitrobenzyl alcohol and pure water and stir evenly;

[0043] S4: Stir evenly and cool to room temperature.

Embodiment 3

[0045]

[0046] S1: Weigh the product according to the above formula for later use; heat ethylene glycol and diethylene glycol to 135°C, then add organic high molecular polymer to dissolve completely;

[0047] S2: After the organic high molecular polymer is completely dissolved, cool down to 130°C, then add ammonium pentaborate, mannitol, ammonium sebacate, ammonium dodecanoate, and 2-butylammonium suberate, at 120°C keep warm for 1 hour;

[0048] S3: After keeping warm for 1 hour, cool down to 85°C, add monobutyl phosphoric acid, ammonium hypophosphite, p-nitrobenzyl alcohol and pure water and stir evenly;

[0049] S4: Stir evenly and cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com