Electrolyte suitable for high-voltage aluminum electrolytic capacitor and preparation method thereof

A technology of aluminum electrolytic capacitors and electrolytes, which is applied in the manufacture of electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of poor electrolyte performance, poor high and low temperature resistance, and the service life of aluminum electrolytic capacitors cannot be further improved. Application prospect, effect of service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

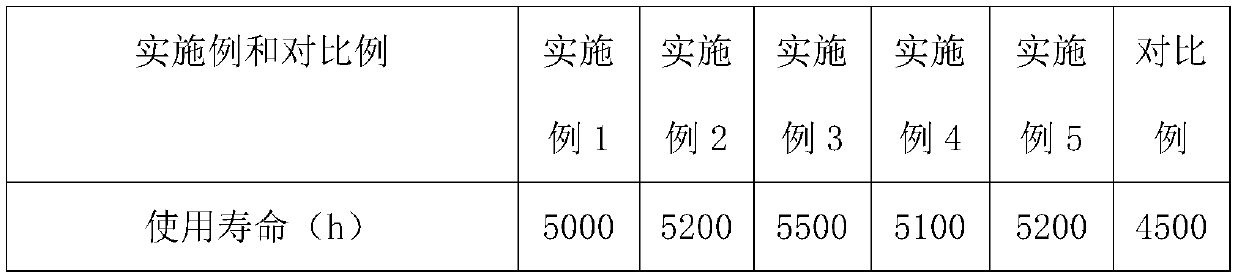

Examples

Embodiment 1

[0023] An electrolyte suitable for high-voltage aluminum electrolytic capacitors, comprising the following raw materials in parts by weight: 40 parts of 4-hydroxybutyrolactone, 60 parts of polyethylene glycol, 50 parts of ethylene glycol, 30 parts of ethylene carbonate, carbonic acid 40 parts of propylene ester, 30 parts of diethyl carbonate, 20 parts of dimethyl carbonate, 10 parts of ethyl methyl carbonate, 20 parts of ammonium azelate, 30 parts of ammonium dodecanoate, 10 parts of benzoic acid, 40 parts of ammonium formate , 40 parts of diammonium hydrogen phosphate, 30 parts of phthalic acid, 10 parts of boric acid, 10 parts of p-nitrophenol, 5 parts of sodium hypophosphite, 10 parts of o-nitroanisole, and 20 parts of monobutyl phosphate.

[0024] In this embodiment, the steps of the preparation method of the electrolyte suitable for high-voltage aluminum electrolytic capacitors are as follows:

[0025] 1) 4-hydroxybutyrolactone, polyethylene glycol, ethylene glycol, ethyl...

Embodiment 2

[0031] An electrolyte suitable for high-voltage aluminum electrolytic capacitors, comprising the following raw materials in parts by weight: 45 parts of 4-hydroxybutyrolactone, 65 parts of polyethylene glycol, 55 parts of ethylene glycol, 35 parts of ethylene carbonate, carbonic acid 45 parts of acrylate, 32 parts of diethyl carbonate, 23 parts of dimethyl carbonate, 12 parts of ethyl methyl carbonate, 25 parts of ammonium azelate, 35 parts of ammonium dodecanoate, 15 parts of benzoic acid, 45 parts of ammonium formate , 42 parts of diammonium hydrogen phosphate, 32 parts of phthalic acid, 12 parts of boric acid, 12 parts of p-nitrophenol, 6 parts of sodium hypophosphite, 12 parts of o-nitroanisole, and 22 parts of monobutyl phosphate.

[0032] In this embodiment, the steps of the preparation method of the electrolyte suitable for high-voltage aluminum electrolytic capacitors are as follows:

[0033] 1) 4-hydroxybutyrolactone, polyethylene glycol, ethylene glycol, ethylene car...

Embodiment 3

[0039] An electrolyte suitable for high-voltage aluminum electrolytic capacitors, comprising the following raw materials in parts by weight: 50 parts of 4-hydroxybutyrolactone, 70 parts of polyethylene glycol, 60 parts of ethylene glycol, 40 parts of ethylene carbonate, carbonic acid 50 parts of acrylate, 35 parts of diethyl carbonate, 25 parts of dimethyl carbonate, 15 parts of ethyl methyl carbonate, 30 parts of ammonium azelate, 40 parts of ammonium dodecanoate, 20 parts of benzoic acid, 50 parts of ammonium formate , 45 parts of diammonium hydrogen phosphate, 35 parts of phthalic acid, 15 parts of boric acid, 15 parts of p-nitrobenzene, 8 parts of sodium hypophosphite, 15 parts of o-nitroanisole, and 25 parts of monobutyl phosphate.

[0040] In this embodiment, the steps of the preparation method of the electrolyte suitable for high-voltage aluminum electrolytic capacitors are as follows:

[0041] 1) 4-hydroxybutyrolactone, polyethylene glycol, ethylene glycol, ethylene ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com