High-voltage high-conductivity electrolytic solution for aluminum electrolytic capacitor

An aluminum electrolytic capacitor, high conductance technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of flashover voltage and conductivity not high enough, and achieve the characteristics of not easy to produce gas, good voltage resistance, and small loss change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

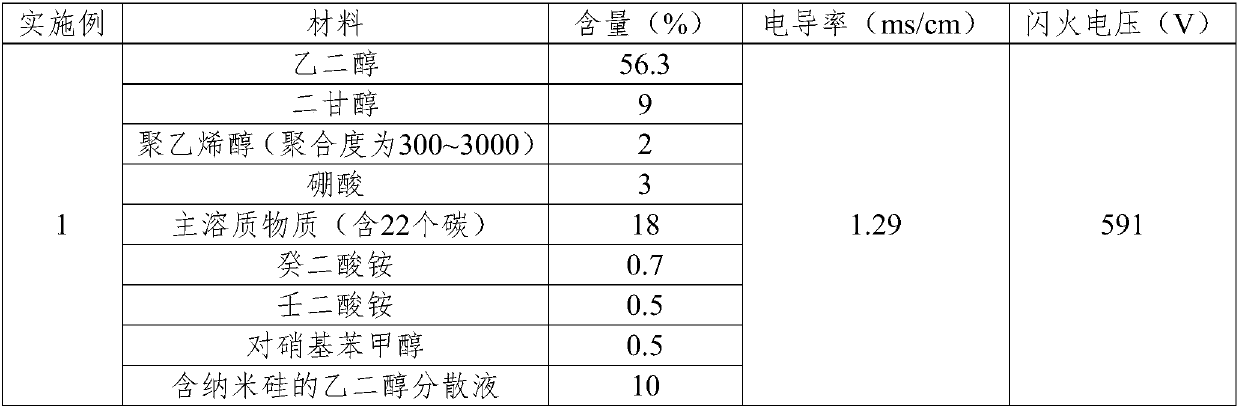

[0026] This embodiment is used to illustrate the electrolytic solution for a high-voltage high-conductivity aluminum electrolytic capacitor disclosed in the present invention.

[0027] The electrolyte composition, conductivity and flashover voltage of the high-voltage high-conductivity aluminum electrolytic capacitor provided in this embodiment are shown in the following table.

[0028] Wherein, the preparation method of the electrolyte solution is as follows: heating ethylene glycol and diethylene glycol to 135° C. to 150° C., adding polyvinyl alcohol, stirring and dissolving until the solution is clear and transparent. Then lower the temperature to 125°C-130°C, add boric acid and mannitol, and keep it open for 30-45 minutes. After the heat preservation is completed, cool down to 110°C, add the main solute, ammonium sebacate, azelaic acid, p-nitrobenzyl alcohol and dispersion liquid containing nano-silicon, keep the temperature at 90°C-100°C, and keep warm for 30-45min . Af...

Embodiment 2

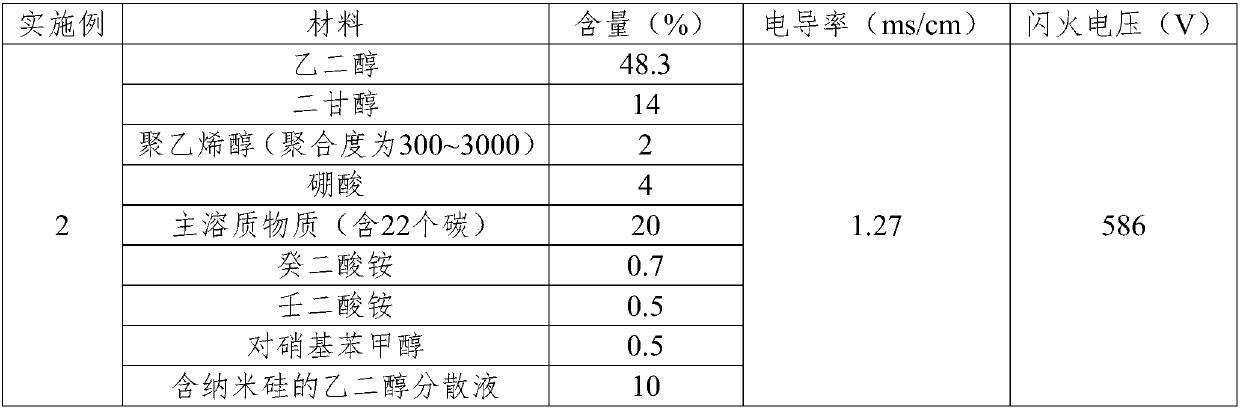

[0032] This embodiment is used to illustrate the electrolytic solution for a high-voltage high-conductivity aluminum electrolytic capacitor disclosed in the present invention.

[0033] The electrolyte composition, conductivity and flashover voltage of the high-voltage high-conductivity aluminum electrolytic capacitor provided in this embodiment are shown in the following table.

[0034] Wherein, the preparation method of the electrolyte solution is as follows: heating ethylene glycol and diethylene glycol to 135° C. to 150° C., adding polyvinyl alcohol, stirring and dissolving until the solution is clear and transparent. Then lower the temperature to 125°C-130°C, add boric acid and mannitol, and keep it open for 30-45 minutes. After the heat preservation is completed, cool down to 110°C, add the main solute, ammonium sebacate, azelaic acid, p-nitrobenzyl alcohol and dispersion liquid containing nano-silicon, keep the temperature at 90°C-100°C, and keep warm for 30-45min . Af...

Embodiment 3

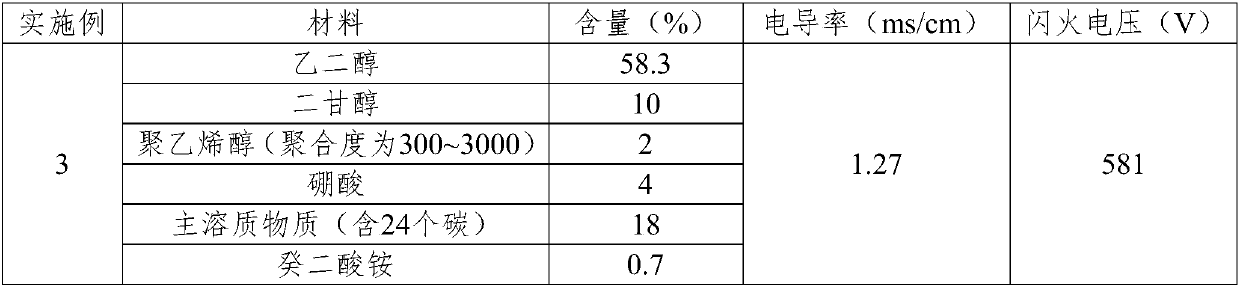

[0038] This embodiment is used to illustrate the electrolytic solution for a high-voltage high-conductivity aluminum electrolytic capacitor disclosed in the present invention.

[0039] The electrolyte composition, conductivity and flashover voltage of the high-voltage high-conductivity aluminum electrolytic capacitor provided in this embodiment are shown in the following table.

[0040] Wherein, the preparation method of the electrolyte solution is as follows: heating ethylene glycol and diethylene glycol to 135° C. to 150° C., adding polyvinyl alcohol, stirring and dissolving until the solution is clear and transparent. Then lower the temperature to 125°C-130°C, add boric acid and mannitol, and keep it open for 30-45 minutes. After the heat preservation is completed, cool down to 110°C, add the main solute, ammonium sebacate, azelaic acid, p-nitrobenzyl alcohol and dispersion liquid containing nano-silicon, keep the temperature at 90°C-100°C, and keep warm for 30-45min . Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com