Water-soluble cutting fluid

A cutting fluid, water-soluble technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of short service life, poor versatility, environmental pollution, etc., and achieve the effect of human and environmental friendliness, excellent resistance to hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

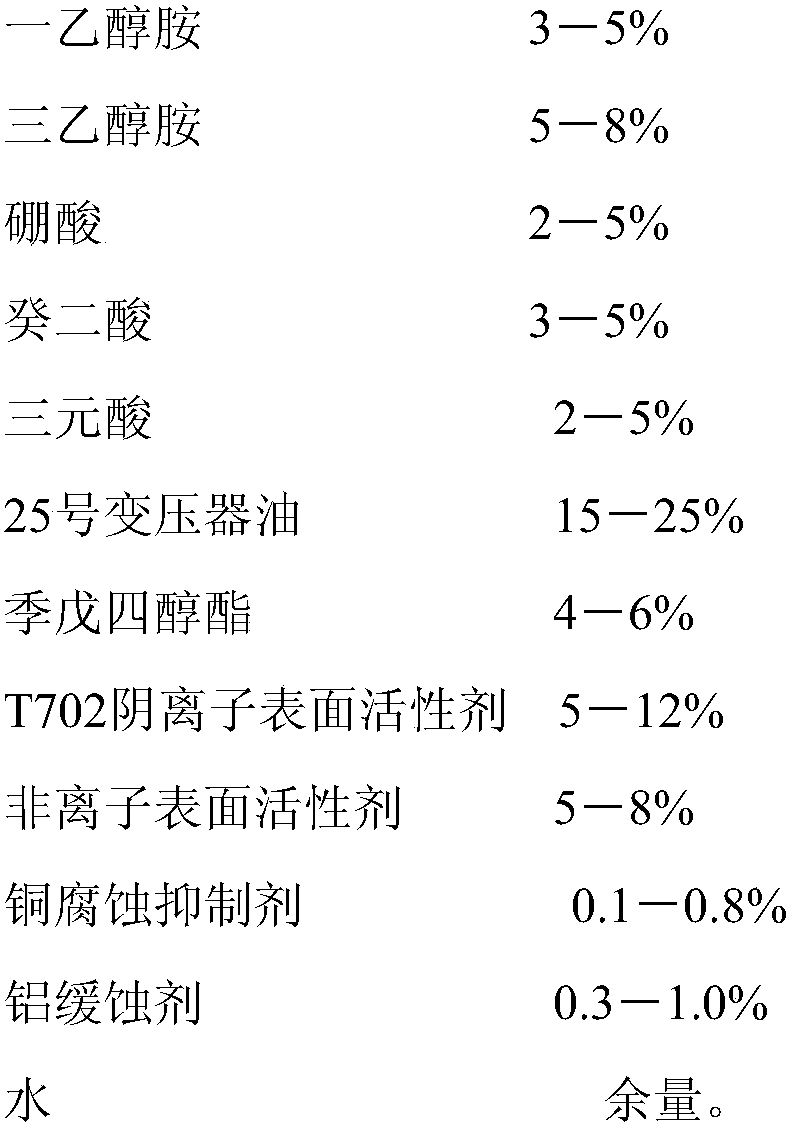

[0018] A kind of water-soluble cutting fluid, its raw material component and its weight are respectively:

[0019]

[0020] The preparation method of above-mentioned water-soluble cutting fluid, its step is:

[0021] (1) Put monoethanolamine, triethanolamine, boric acid, sebacic acid, tribasic acid, and copper corrosion inhibitor into water, heat at 50-60°C to react into a complex agent as a raw material monomer, and set aside;

[0022] ⑵ Add base oil, synthetic ester, surfactant, corrosion inhibitor, and stir well to the water in order to obtain an emulsion; ⑶ Mix and stir the compounding agent and emulsion until it becomes a uniform and transparent liquid.

Embodiment 2

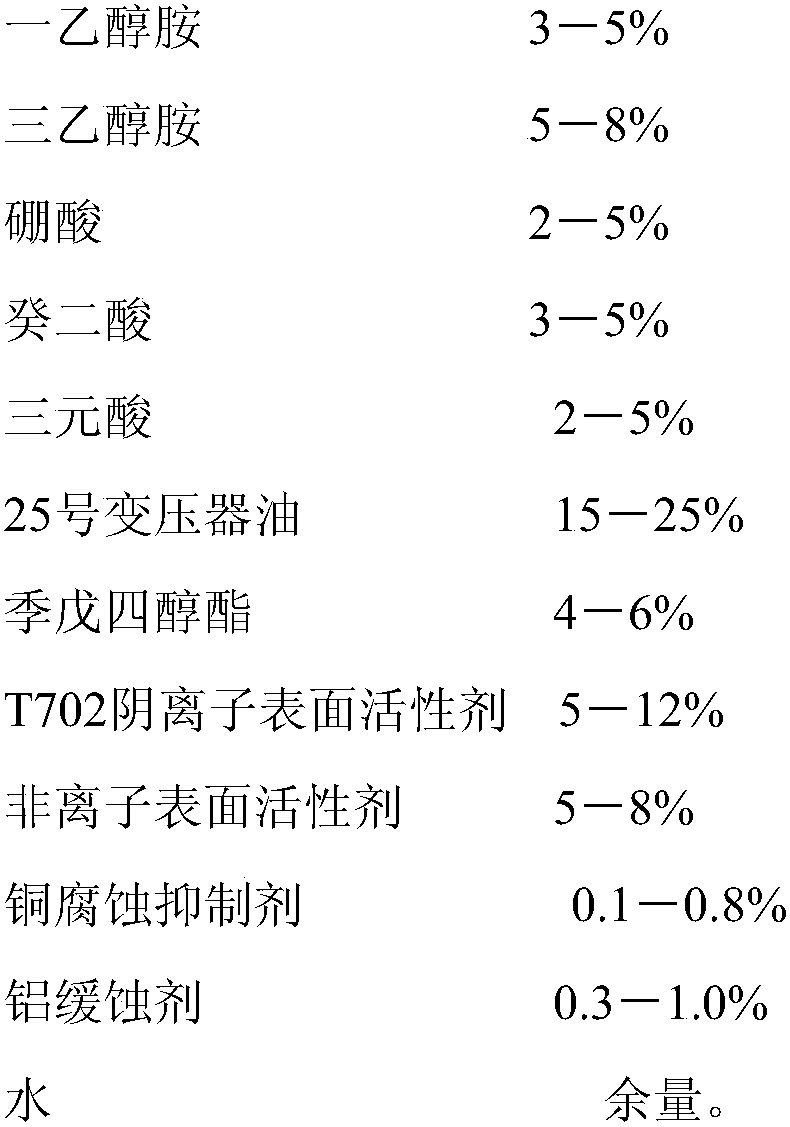

[0024] A kind of water-soluble cutting fluid, its raw material component and its weight are respectively:

[0025]

[0026] The preparation method of the above-mentioned water-soluble cutting fluid is the same as that in Example 1.

Embodiment 3

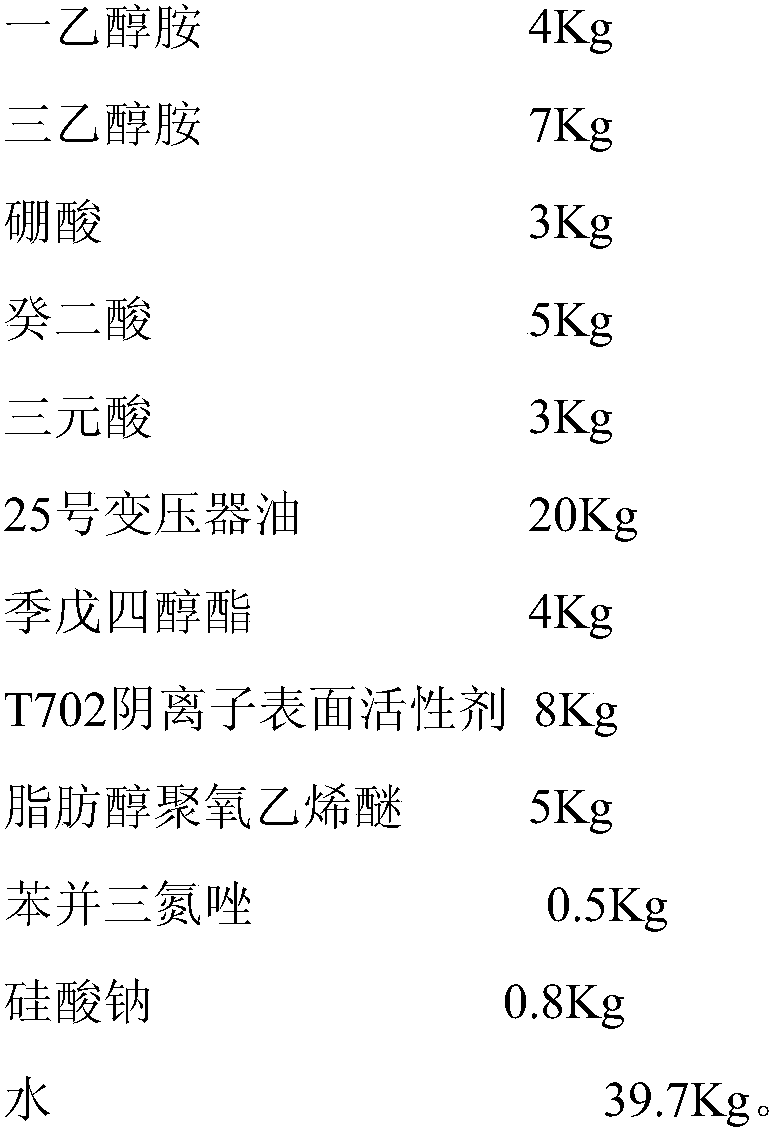

[0028] A kind of water-soluble cutting fluid, its raw material component and its weight are respectively:

[0029]

[0030]

[0031] The preparation method of the above-mentioned water-soluble cutting fluid is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com