Tung oil source epoxy plasticizer product having function of heat stabilizer, preparation method thereof and application thereof

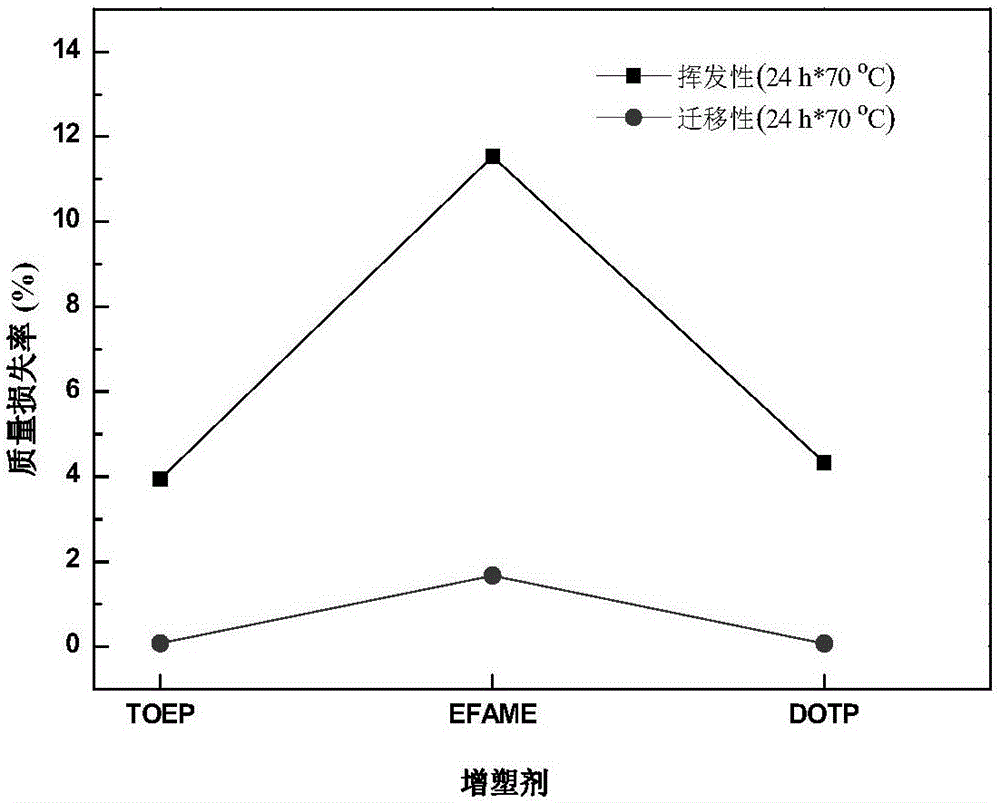

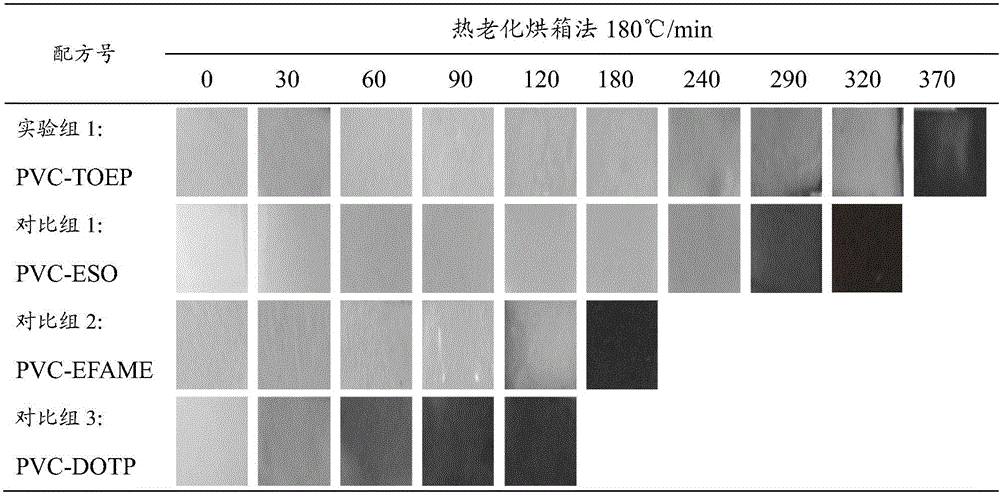

A technology of epoxy plasticizer and thermal stabilizer, applied in the field of plastic additives, can solve the problems of poor thermal stability, low migration, low volatility, etc., to improve migration resistance, improve thermal stability, and promote high added The effect of value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step is to prepare tung oil-derived polybasic esters: take 420 parts by mass of methyl chelate and 1.2 parts by mass of hydroquinone in a reaction bottle, add 140 parts by mass of methyl acrylate and 30 parts by mass of Dimethyl maleate, after the dropwise addition, keep warm at 180°C for 4 hours, and collect fractions at 150°C to 250°C under vacuum to obtain tung oil-derived polybasic esters.

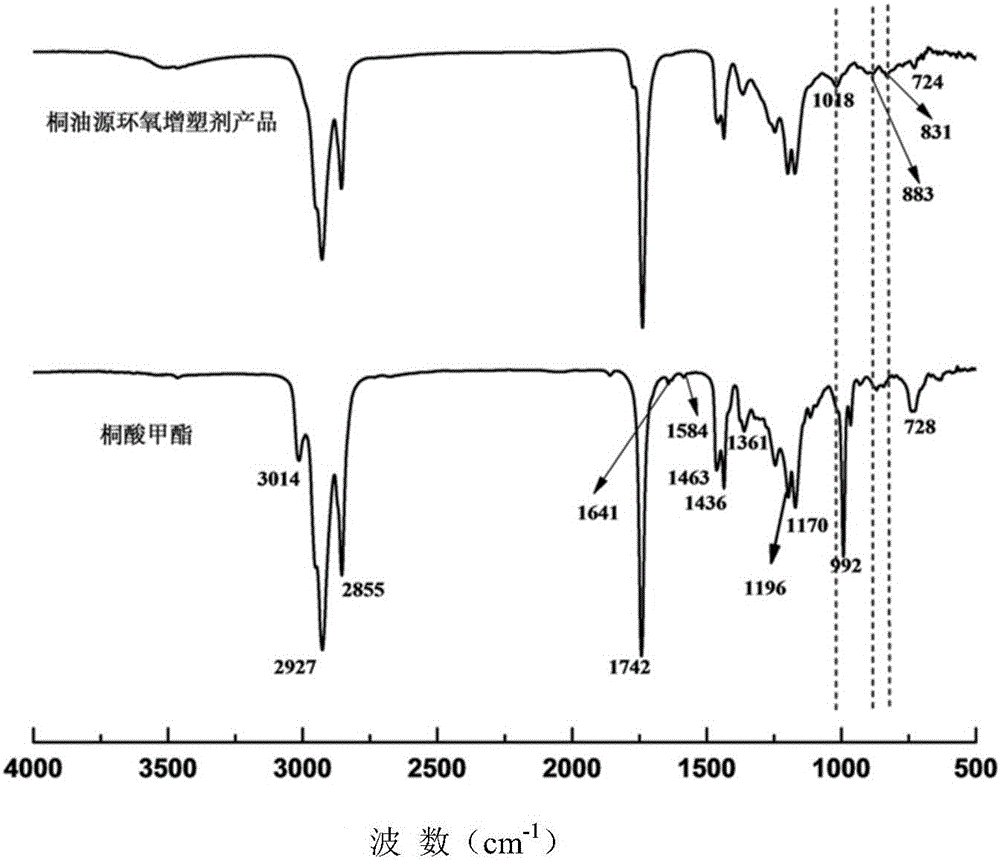

[0024] The second step, tung oil source epoxy plasticizer product: take 100 mass parts of the above-mentioned tung oil source polybasic acid ester and add in the reaction bottle, add 12 mass parts formic acid, 0.5 mass parts phosphoric acid at room temperature, after heating up to 60 ℃, Add dropwise 130 parts by mass of 37wt.% H 2 o 2 Aqueous solution, keep warm for 5h after the completion of the dropwise addition, after the reaction is over, let it stand for stratification, divide the lower layer of acid water, and use the mass fraction of the upper layer of oil laye...

Embodiment 2

[0027] The first step is to prepare polybasic esters derived from tung oil: take 420 parts by mass of methyl chelate and 1 to 4.3 parts by mass of hydroquinone in a reaction bottle, and add 95 parts by mass of methyl acrylate and 70 parts by mass of Dimethyl maleate, after the dropwise addition, keep warm at 180°C for 5 hours, and collect fractions at 200°C to 260°C under vacuum conditions to obtain tung oil-derived polybasic esters.

[0028] The second step, tung oil source epoxy plasticizer product: take 100 mass parts of the above-mentioned tung oil source polybasic ester and add in the reaction bottle, add 13 mass parts formic acid, 1 mass part sulfuric acid at room temperature, after heating up to 60 ℃, Add dropwise 135 parts by mass of 37wt.% H 2 o 2 Aqueous solution, keep warm for 5.5h after the completion of the dropwise addition, after the reaction is over, let it stand for stratification, separate the lower layer of acid water, and use 4wt.% NaHCO with a mass fracti...

Embodiment 3

[0030] The first step is to prepare tung oil-derived polybasic esters: take 420 parts by mass of methyl trophic acid and 4.3 parts by mass of hydroquinone in a reaction bottle, add 370 parts by mass of diethyl maleate dropwise at 180 ° C, drop After the addition, keep the temperature at 190°C for 7 hours, and collect fractions at 210°C to 260°C under vacuum conditions to obtain tung oil-derived polybasic esters.

[0031] Second step, tung oil source epoxy plasticizer product: get 100 mass parts of above-mentioned tung oil source polybasic acid esters and add in the reaction bottle, add 13 mass parts formic acid, 2 mass parts p-toluenesulfonic acid at room temperature, be warming up to 60 After ℃, drop 150 parts by mass of 37wt.% H 2 o 2 Aqueous solution, keep warm for 8h after the dropwise addition is completed, after the reaction is over, let stand to separate layers, separate the lower layer of acid water, and use the mass fraction of the upper layer of oil layer to be 3wt....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com