Highlight polyester resin for coil steel household appliance finish paint as well as preparation method and application thereof

A technology for polyester resin and home appliances, which is applied in the field of high-gloss polyester resin and its preparation for the topcoat of coil steel appliances, to achieve the effects of reducing the occurrence probability of particles and particle lines on the board surface, excellent chemical resistance, and improving whiteness and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

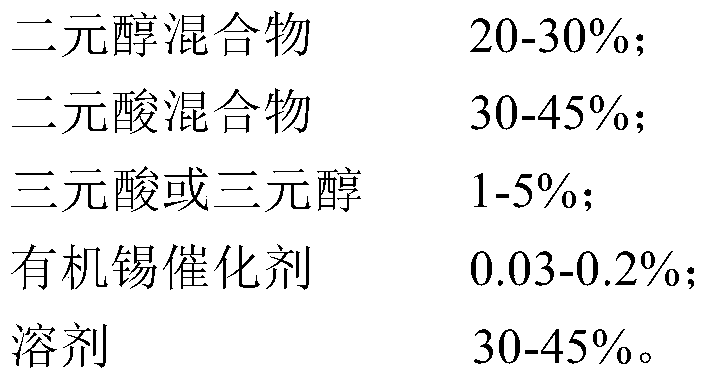

[0070] Another specific embodiment of the present invention provides a method for preparing the high-gloss polyester resin for coiled steel household appliances as described above, comprising the following steps:

[0071] Mix the organotin catalyst, diol mixture and part of the dibasic acid mixture in the reactor to react to obtain the prepolymer;

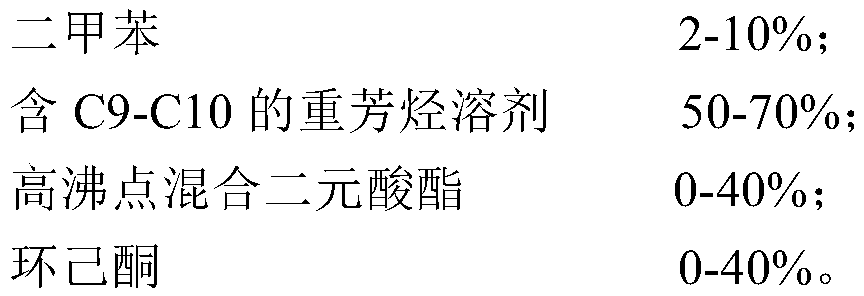

[0072] Continue to add the remaining dibasic acid mixture, tribasic acid or tribasic alcohol into the reaction kettle, gradually raise the temperature to 220-240°C, react until the reactant is clear and transparent, reflux until the acid value is 0-5mg KOH / g, the hydroxyl value 60-80 mg KOH / g; lower the temperature, add a solvent to dilute until the Gardner viscosity is Z-Z4 at 25°C, and obtain the high-gloss polyester resin for coiled steel appliances.

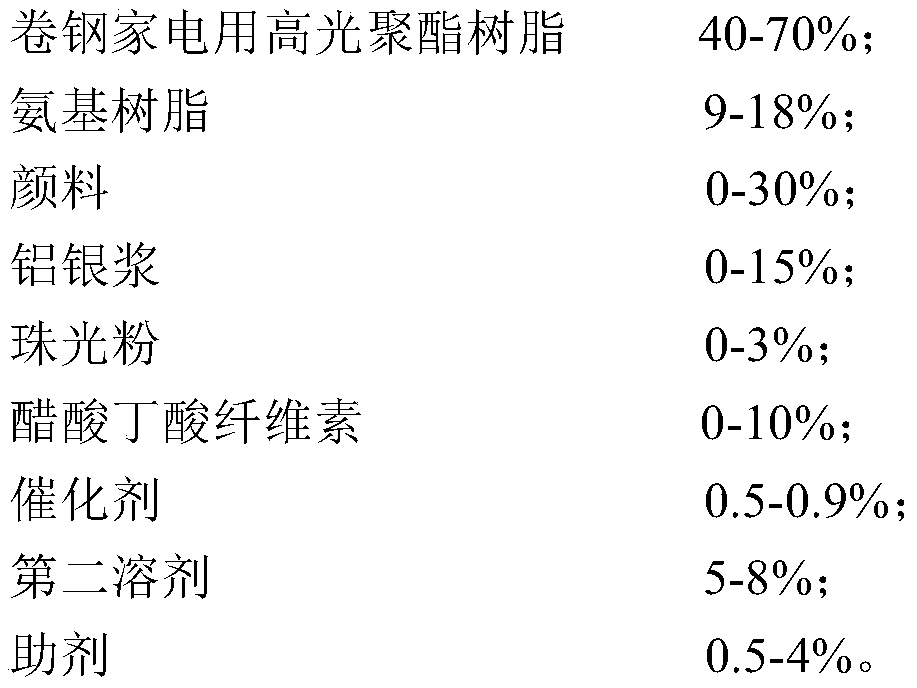

[0073] Yet another specific embodiment of the present invention provides a top coat for steel coil appliances, wherein the raw materials of the top paint for coil steel home appli...

Embodiment 1

[0111] Saturated polyester resin A1, the preparation method comprises the following steps:

[0112] The first stage:

[0113] Neopentyl glycol: 319 g, 2-methyl-1,3-propanediol: 146 g, terephthalic acid: 240 g, and catalyst: 1.3 g were put into the reactor. Under the condition of blowing nitrogen, slowly heat to 215°C to react to form a prepolymer, react until the acid value is less than 1mgKOH / g and the prepolymer is clear and transparent at 215°C, then cool to 160°C.

[0114] second stage:

[0115] At 160°C, put isophthalic acid: 348g, adipic acid: 160g, trimellitic anhydride: 49g into the reactor, continue heating to 238-240°C, and control the reaction time within 10 hours until the polyester resin It is clear and transparent at the reaction temperature, and then slowly add about 28g of xylene for reflux until the reaction reaches an acid value of less than 5mg KOH / g, and the water output is about 160-170g. At this time, the temperature was lowered to 80° C., and 572 g of...

Embodiment 2

[0117] Saturated polyester resin A2, preparation method comprises the following steps:

[0118] The first stage:

[0119] Neopentyl glycol: 425 g, 2-methyl-1,3-propanediol: 110 g, and terephthalic acid: 134 g were put into the reaction kettle. Catalyst: 0.95 g. Under the condition of blowing nitrogen, slowly heat to 215°C to react to form a prepolymer, react until the acid value is less than 1mgKOH / g and the prepolymer is clear and transparent at 215°C, then cool to 160°C.

[0120] second stage:

[0121] At 160°C, put isophthalic acid: 303g, adipic acid: 254g, trimellitic anhydride: 43g into the reactor, continue heating to 238-240°C, and control the reaction time within 10 hours until the polyester resin It is clear and transparent at the reaction temperature, and then slowly add about 28g of xylene for reflux until the reaction reaches an acid value of less than 5mg KOH / g, and the water output is about 160-170g. At this time, the temperature was lowered to 80° C., and 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com