Red-mud citric acid dealkalizing technique

A technology of citric acid and red mud, which is applied in the field of comprehensive treatment of red mud, can solve the problems of large consumption of chemicals, high liquid-solid ratio, red mud cannot be used for preparation, etc., and achieve the effect of reducing the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

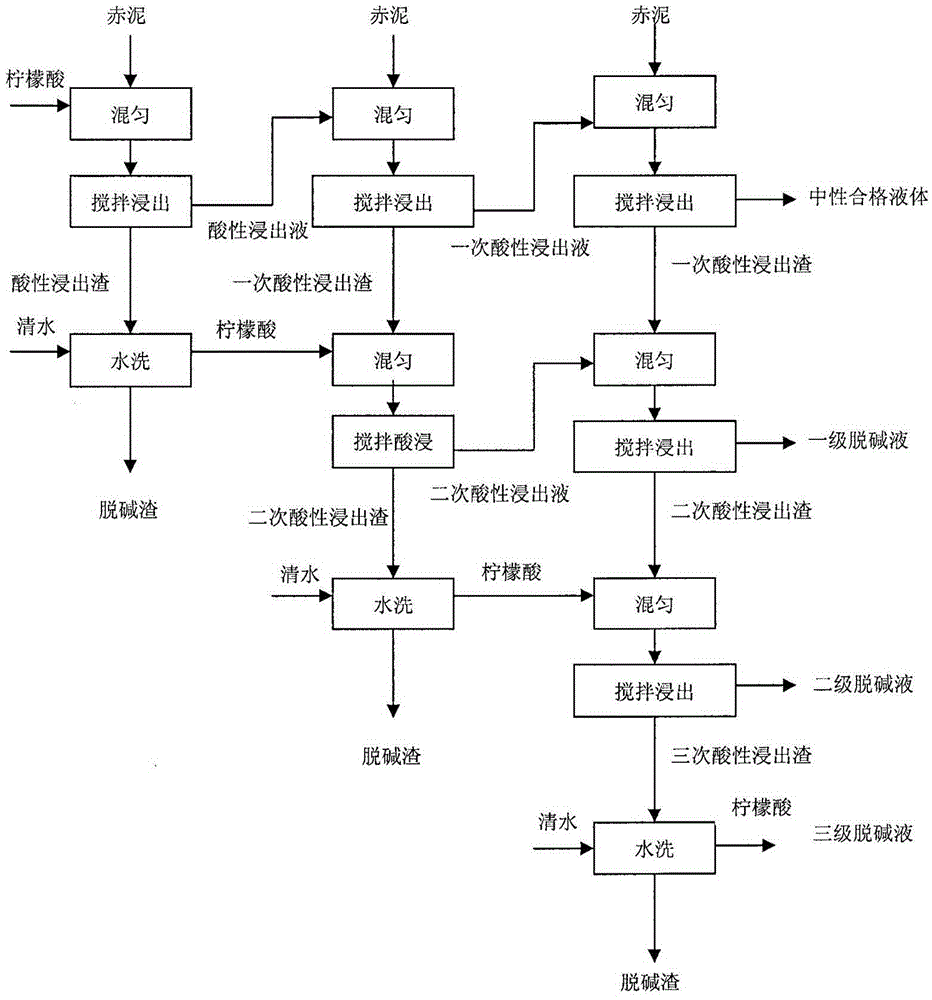

Method used

Image

Examples

Embodiment 1

[0026] The first batch of red mud is subjected to a stirring leaching and a water washing:

[0027] The first batch of red mud and citric acid added in an amount of 12%~15% by mass of red mud are stirred and leached under the condition of a liquid-solid mass ratio of 3~5:1. The leaching process is carried out at a temperature of 30~40°C, The stirring time is 90~120min and the stirring intensity is 100~150r / min. After the stirring is completed, the ore pulp is press-filtered to obtain acidic leaching residue and acidic leaching solution. The acidic leaching solution is the primary dealkalization solution of the first batch of red mud. After washing with water, the first batch of dealkalization slag and washing liquid of red mud are obtained, and then citric acid with a mass percentage of 7% to 8% of the washing liquid is added to the washing liquid to obtain the second-stage dealkalization liquid of the first batch of red mud.

[0028] The second batch of red mud is subjected t...

Embodiment 2

[0036] The first batch of red mud is subjected to a stirring leaching and a water washing:

[0037] The first batch of red mud and citric acid added in an amount of 9%~12% by mass of red mud are stirred and leached under the condition of a liquid-solid mass ratio of 3~5:1. The leaching process is carried out at a temperature of 40~50°C, The stirring time is 90~120min and the stirring intensity is 100~150r / min. After the stirring is completed, the ore pulp is press-filtered to obtain acidic leaching residue and acidic leaching solution. The acidic leaching solution is the primary dealkalization solution of the first batch of red mud. After washing with water, the first batch of red mud dealkalization slag and washing liquid are obtained, and then citric acid with a mass percentage of 6% to 7% of the washing liquid is added to the washing liquid to obtain the second batch of red mud dealkalization liquid.

[0038] The second batch of red mud is subjected to a second stirring lea...

Embodiment 3

[0046] The first batch of red mud is subjected to a stirring leaching and a water washing:

[0047] The first batch of red mud and citric acid added in an amount of 6%~9% by mass of red mud are stirred and leached under the condition of a liquid-solid mass ratio of 3~5:1. The leaching process is carried out at a temperature of 50~60°C, The stirring time is 90~120min and the stirring intensity is 100~150r / min. After the stirring is completed, the ore pulp is press-filtered to obtain acidic leaching residue and acidic leaching solution. The acidic leaching solution is the primary dealkalization solution of the first batch of red mud. After washing with water, the first batch of red mud dealkalization slag and washing liquid are obtained, and then citric acid with a mass percentage of 5% to 6% of the washing liquid is added to the washing liquid to obtain the first batch of red mud secondary dealkalization liquid.

[0048] The second batch of red mud is subjected to a second stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com