Preparation method of environment-friendly type tapping liquid for cover plate of filter of automobile air conditioner and environment-friendly type tapping liquid

A filter cover, automobile air-conditioning technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of easy decomposition during processing, short service life of tapping fluid, corrosion of machine tool taps, etc., and achieve environmental protection and effective Benefits to human health and prolongs lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

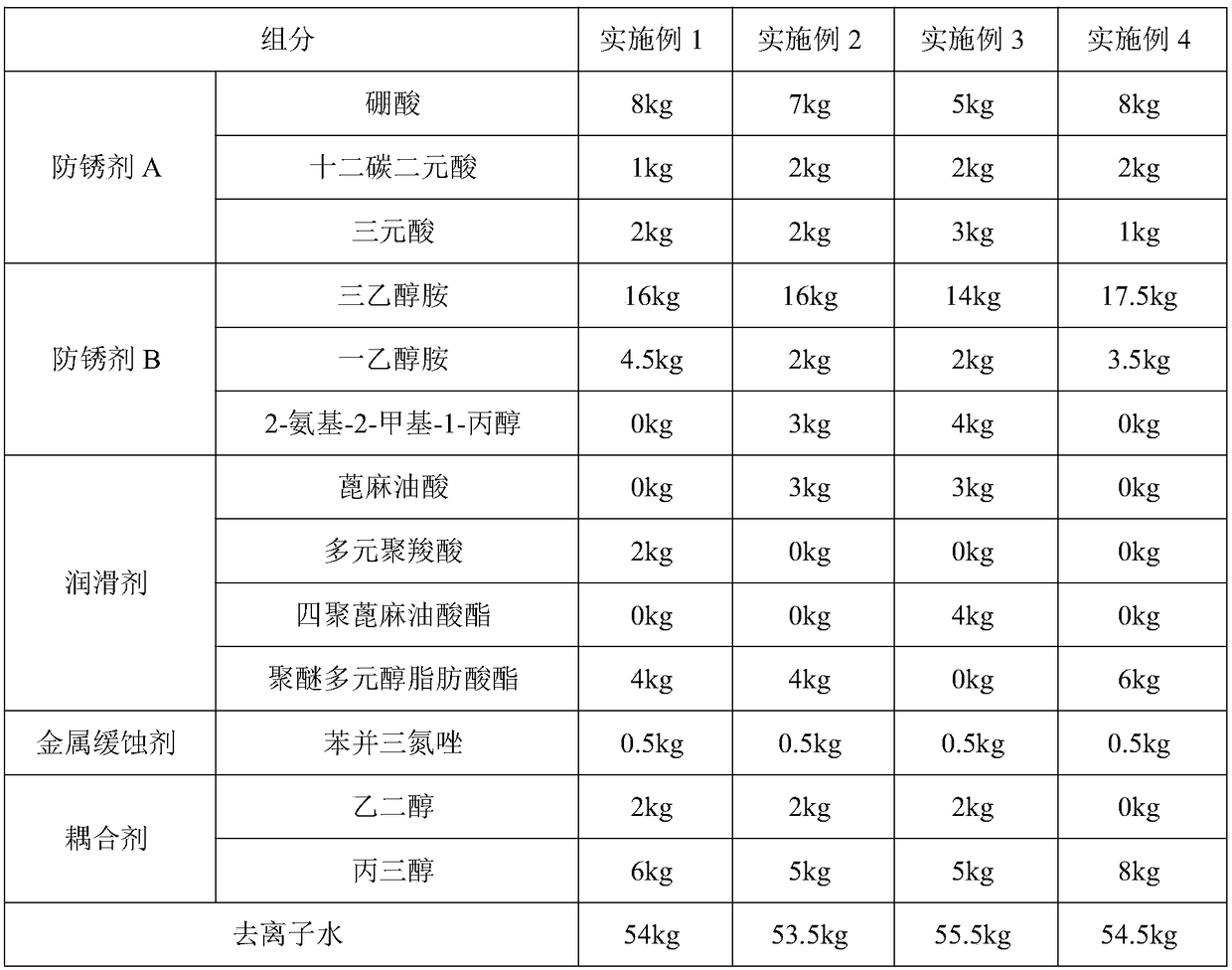

[0046] Take raw materials according to Table 1;

[0047] Add rust inhibitor A and metal corrosion inhibitor to deionized water by weight, stir at 300rpm for 15min, heat up from room temperature to 50°C at a speed of 1.3°C / min, and then keep warm to prepare the first mixture;

[0048] Add rust inhibitor B to the first mixture, stir at 500 rpm for 20 minutes, and at the same time raise the temperature from 50°C to 85°C at a rate of 0.8°C / min to prepare the second mixture;

[0049] Add the lubricant and coupling agent to the second mixture, stir at 300rpm for 30min until uniform, cool and precipitate, and filter to obtain an environmentally friendly tapping fluid.

Embodiment 2

[0051] Take raw materials according to Table 1;

[0052] Add rust inhibitor A and metal corrosion inhibitor into deionized water by weight, stir at 500rpm for 10min, heat up from room temperature to 45°C at a speed of 1.3°C / min, and then keep warm to prepare the first mixture;

[0053] Add rust inhibitor B to the first mixture, stir at 300 rpm for 30 minutes, and at the same time raise the temperature from 45°C to 75°C at a rate of 0.8°C / min to prepare the second mixture;

[0054] Add the lubricant and coupling agent to the second mixture, stir at 500rpm for 20 until uniform, cool and precipitate, and filter to obtain an environmentally friendly tapping fluid.

Embodiment 3

[0056] Take raw materials according to Table 1;

[0057] Add antirust agent A and metal corrosion inhibitor into deionized water by weight, stir at 400rpm for 12min, heat up from room temperature to 50°C at a speed of 1.3°C / min, and then keep warm to prepare the first mixture;

[0058] Add rust inhibitor B to the first mixture, stir at 300 rpm for 30 minutes, and at the same time raise the temperature from 50°C to 85°C at a rate of 0.8°C / min to prepare the second mixture;

[0059] Add the lubricant and coupling agent to the second mixture, stir at 400rpm for 25min until uniform, cool and precipitate, and filter to obtain an environmentally friendly tapping fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com