Corn microbial seed coating agent and preparation method thereof

A microbial strain and microbial technology, applied in botany equipment and methods, biocides, chemicals for biological control, etc., can solve the problems of difficult storage of coated seeds, easy film peeling, low coating rate, etc. , to achieve good siderophore production capacity, long activity maintenance time, and the effect of promoting seedling growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 corn microbial seed coating agent of the present invention and preparation method thereof

[0038] 1. The formula of seed coating agent BSCA-1

[0039] Active ingredient: Bacillus Velez TXM-1 bacterial liquid ≥ 10 7 cfu mL -1 ;

[0040] Additives: 100 milliliters of water, add film-forming agent 10g, thickener 0.5g, preservative 0.1g, coloring agent 0.5g; wherein, the film-forming agent is composed of sodium alginate and polyvinyl alcohol, SA:PVA= 1:9, the thickener is bentonite, and the preservative is sodium benzoate;

[0041]The volume ratio of the Bacillus velaisi bacteria liquid to the water in the auxiliary agent is 1:1.

[0042] 2. The formula of seed coating agent BSCA-2

[0043] Active ingredient: Bacillus amyloliquefaciens TXM-2 bacterial liquid ≥10 7 cfu mL -1 ;

[0044] Auxiliaries: 10wt% film-forming agent, 0.5wt% thickener, 0.1wt% preservative, 0.5wt% coloring agent; wherein, the film-forming agent is composed of sodium alginate and po...

Embodiment 2

[0058] Example 2 Determination of characteristics of Bacillus velezensis and Bacillus amyloliquefaciens

[0059] 1. Antagonistic properties

[0060] A total of 11 strains were tested, including 7 strains of Bacillus and 4 strains of Trichoderma, which were TXM-1 (Bacillus amyloliquefaciens), TXM-2 (Bacillus Velez), TXM-3 (Bacillus amyloliquefaciens), TXM-4 (Bacillus pumilus), TXM-5 (Bacillus subtilis), TXM-6 (Bacillus amyloliquefaciens), TXM-7 (Bacillus cereus), TXMT-2 (Trichoderma reesei), TXMT- 3 (T. reesei), TXMT-4 (T. harzianum) and TXMT-5 (T. viride).

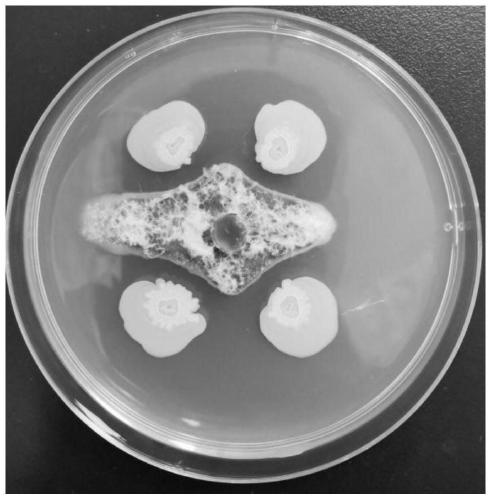

[0061] Use a hole puncher to punch holes on the Trichoderma and the pathogenic bacteria, and pick one piece to the center of the two sides of the plate with a distance of 5-6 cm. For Bacillus, use the tip of a pipette to point at a distance of 2 to 3 cm from the pathogen block, and place it in an incubator at 28°C for upside-down cultivation. The pathogen plate cultured alone is used as a control, see Figure 3-4 .

[...

Embodiment 3

[0076] Embodiment 3 contains the performance of the microbial seed coating agent of different film-forming agents

[0077] The microbial seed coating agent in the present embodiment except film-forming agent, all the other compositions are identical with embodiment 1.

[0078] 1. Effects on the growth of corn seedlings

[0079] Soak the corn seeds in 75% ethanol for surface disinfection and air-dry; then coat the corn seeds with microbial seed coating agents containing different compositions of film-forming agents. The film-forming time is all within 5 minutes, dry at room temperature, and finally Place them in germination boxes soaked with two layers of filter paper, and cultivate them at room temperature.

[0080] Each process 10 seeds, three repetitions; After 7 days, calculate germination rate, after 14 days, measure root length, stem length, leaf length, leaf width and seed vigor index (VI), see table 3 and Figure 6 .

[0081] Table 3 Effects of different ratios of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com