Preparation process of total synthesis cutting liquid with high lubricating property and high temperature resistance

A technology of preparation technology and lubricity, applied in the field of preparation technology of fully synthetic cutting fluid, can solve problems such as difficult machining and increased processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

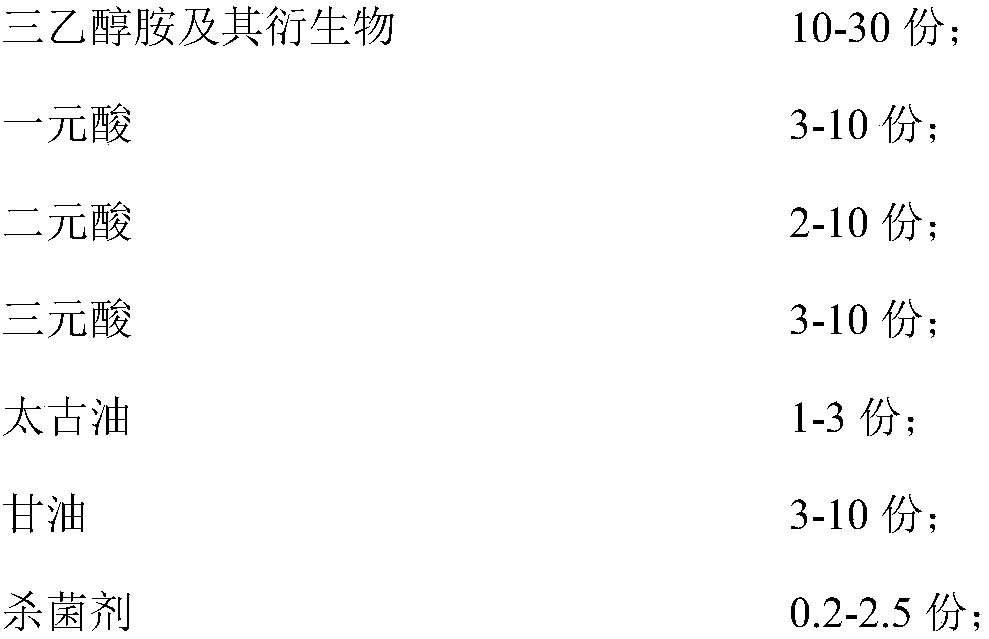

[0027] The preparation process of the fully synthetic cutting fluid provided by the present invention will be described in detail below.

[0028] The present invention provides a preparation process of high lubricity and high temperature resistant fully synthetic cutting fluid, the preparation method is as follows:

[0029] S01 Add the raw material triethanolamine and its derivatives into water, start stirring and heating, stir evenly, and heat;

[0030] S02 Add raw materials monobasic acid and dibasic acid in sequence, and stir until completely dissolved;

[0031] S03 Add the raw materials Taikoo oil and tribasic acid in sequence, and stir until completely dissolved;

[0032] S04 Add raw material glycerin and bactericide, stir until uniform and transparent;

[0033] After S05 is properly cooled to room temperature, it can be discharged.

[0034] In the above S02, if the polybasic acid or tribasic acid is a granular solid, proper heating can increase the dissolution.

[00...

Embodiment approach

[0042] As an embodiment of the present invention, the aliphatic carboxylic acid is selected from glycolic acid, lactic acid, glyceric acid, gluconic acid, salicylic acid, 2-hydroxyisobutyric acid, 3-hydroxybutyric acid, 4-hydroxybutyric acid acid, 2-hydroxy-n-butyric acid, 2-hydroxycaproic acid, 3-hydroxycaproic acid, 4-hydroxycaproic acid, 5-hydroxycaproic acid, 6-hydroxycaproic acid, 2-hydroxypentanoic acid, 3-hydroxypentanoic acid One or more of oleic acid, oleic acid, isooctanoic acid, 4-hydroxypentanoic acid, and hydroxypropylsulfonic acid.

[0043] As a preferred mode of the present invention, in the present invention, the monobasic acid is a mixture of 2-hydroxyisobutyric acid and isooctanoic acid in a weight ratio of 1:1.

[0044] a

[0045] The dibasic acid is composed of aliphatic dibasic acid and naphthenic dibasic acid; the aliphatic dibasic acid is selected from malonic acid, succinic acid, glutaric acid, adipic acid, pimelic acid, suberic acid , azelaic acid,...

Embodiment approach 1

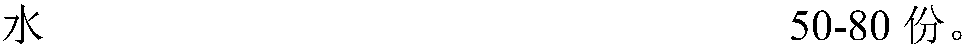

[0066] Embodiment 1. A preparation process of a high lubricity, high temperature resistant fully synthetic cutting fluid, the preparation method is as follows:

[0067] S01 Add the raw material triethanolamine and its derivatives into water, start stirring and heating, stir evenly, and heat;

[0068] S02 Add raw materials monobasic acid and dibasic acid in sequence, and stir until completely dissolved;

[0069] S03 Add the raw materials Taikoo oil and tribasic acid in sequence, and stir until completely dissolved;

[0070] S04 Add raw material glycerin and bactericide, stir until uniform and transparent;

[0071] After S05 is properly cooled to room temperature, it can be discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com