Preparation method of hyperbranched polyamide modified organic silicon resin and paint prepared from resin

A technology of hyperbranched polyamide and organosilicon, applied in the field of polyamide resin, can solve problems such as unsatisfactory hardness of organosilicon resin, and achieve the effects of good hardness and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

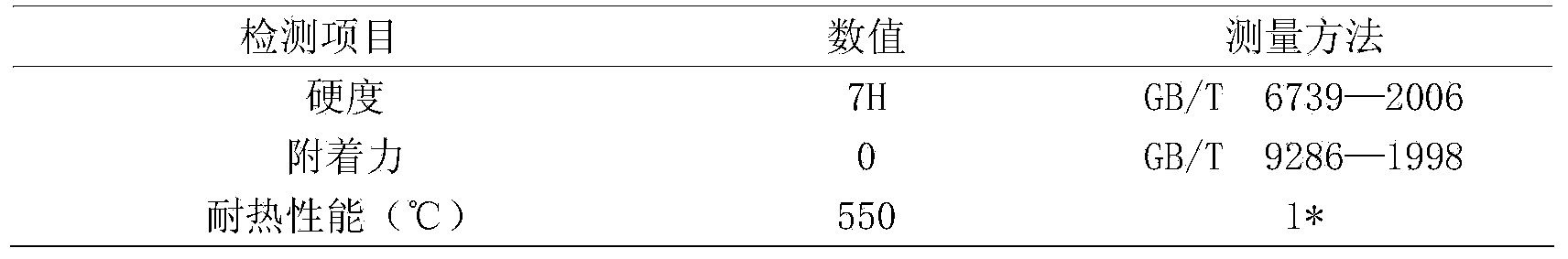

Embodiment 1

[0034] 1) Preparation of aminated ultrafine silica

[0035] a) Formula

[0036] Ultrafine silica: 20g

[0037] γ-Aminopropyltriethoxysilane: 8g

[0038] Toluene: 300g

[0039] b) Preparation process

[0040] Add ultra-fine silica and toluene into a reactor equipped with a condenser tube, a thermometer and a stirrer, disperse evenly at a high speed, add γ-aminopropyltriethoxysilane, heat and reflux for 2 hours; filter under reduced pressure, and dry to obtain Aminated ultrafine silica 26.3g.

[0041] c) Performance

[0042] The particle size of aminated ultrafine silica was detected by DSL, and the result was 100nm;

[0043] The ammonia value of aminated ultrafine silica is determined by acid-base titration, and the specific steps are as follows: First, accurately weigh about 1.5 g of aminated ultrafine silica in a conical flask, add 20 mL of tetrahydrofuran and toluene, and stir Make it disperse evenly; add 3~4 drops of methyl orange indicator, titrate with hydrochloric...

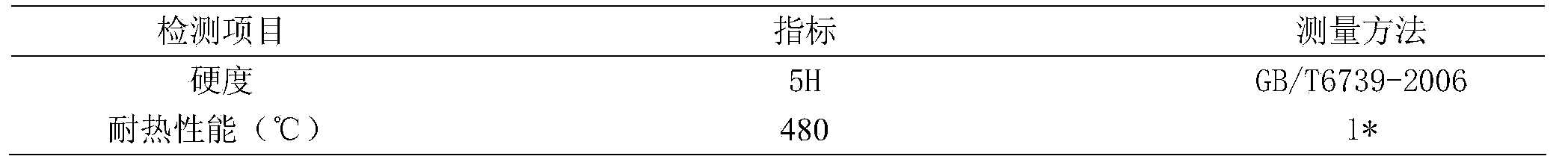

Embodiment 2

[0096] 1) Preparation of aminated ultrafine silica

[0097] a) Formula

[0098] Ultrafine silica: 40g

[0099] γ-(2,3-Glycidoxy)propylmethyldimethoxysilane: 32g

[0100] Toluene: 400g

[0101] b) Preparation process

[0102] Add superfine silicon dioxide and toluene into the reactor equipped with condenser tube, thermometer and stirrer, and add γ-(2,3-glycidoxy)propylmethyldimethoxysilane after high-speed dispersion, Heat to reflux for 5 hours; filter under reduced pressure, and dry to obtain 69.7 g of aminated ultrafine silicon dioxide.

[0103] c) Performance

[0104] The particle size of aminated ultrafine silica was detected by DSL, and the result was 150nm;

[0105] The ammonia value of the aminated ultrafine silicon dioxide is determined by acid-base titration method, and the ammonia value of the aminated ultrafine silicon dioxide prepared above is 2 mmol / g.

[0106] 2) Preparation of silicone oligomers

[0107] a) Composition

[0108] Monomethyltrimethoxysilane...

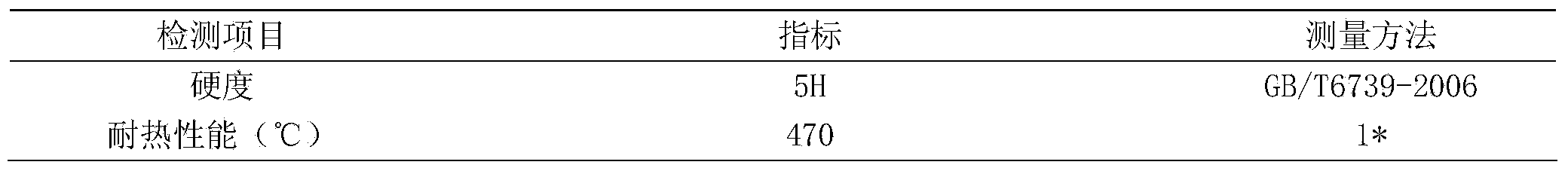

Embodiment 3

[0149] 1) Preparation of aminated ultrafine silica

[0150] a) Formula

[0151] Ultrafine silica: 30g

[0152] γ-Aminopropyltriethoxysilane: 15g

[0153] Toluene: 300g

[0154] b) Preparation process

[0155] Add ultra-fine silica and toluene into the reactor equipped with condenser tube, thermometer and stirrer, disperse evenly at high speed, add γ-aminopropyltriethoxysilane, heat and reflux for 3 hours; filter under reduced pressure, and dry to obtain Aminated ultrafine silica 43.6g.

[0156] c) Performance

[0157] The particle size of aminated ultrafine silica was detected by DSL, and the result was 30nm;

[0158] The ammonia value of the aminated ultrafine silicon dioxide is measured by acid-base titration, and the ammonia value of the above-mentioned prepared aminated ultrafine silicon dioxide is 1.49 mmol / g.

[0159] 2) Preparation of silicone oligomers

[0160] a) Composition

[0161] Monomethyltrimethoxysilane: 42.0g (0.28mol)

[0162] Dimethyldimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com