Cross-linking agent for bio-based adhesive and preparation method of cross-linking agent

A kind of adhesive, bio-based technology, applied in the field of crosslinking agent and its preparation, to achieve the effect of good hot water resistance adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

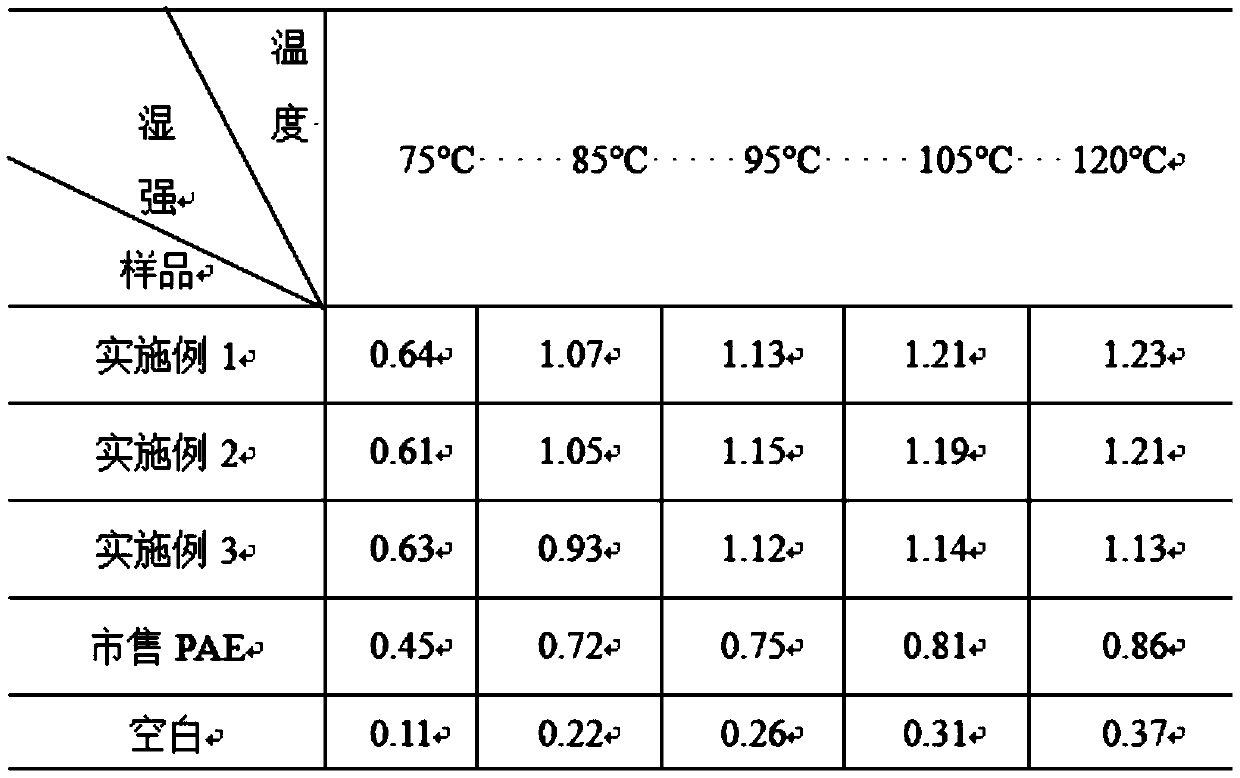

Embodiment 1

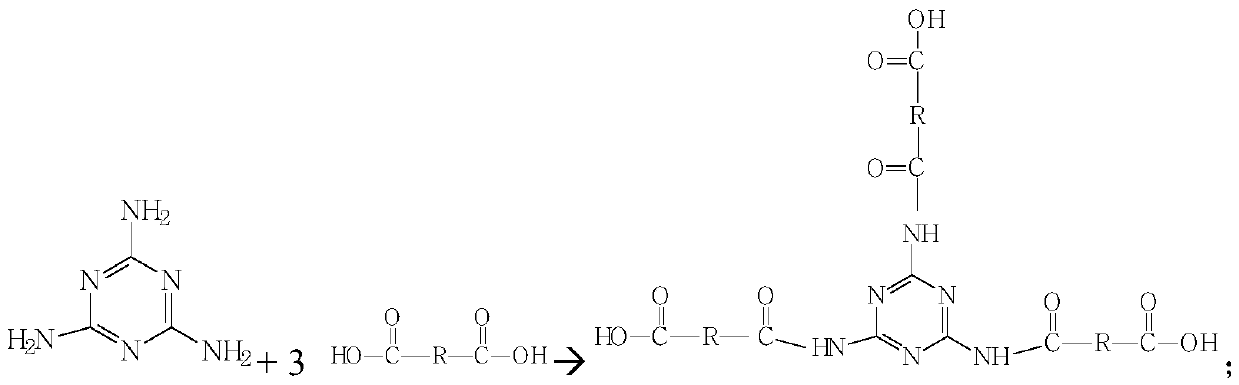

[0024] The cross-linking agent of the present embodiment is to take melamine, adipic acid, diethylenetriamine, epichlorohydrin as main raw materials, by including the following major steps:

[0025] (1) Mix 100 g of melamine and 350 g of adipic acid, heat to 180° C. and react for 120 min, and cool to room temperature to obtain polycondensed tribasic acid;

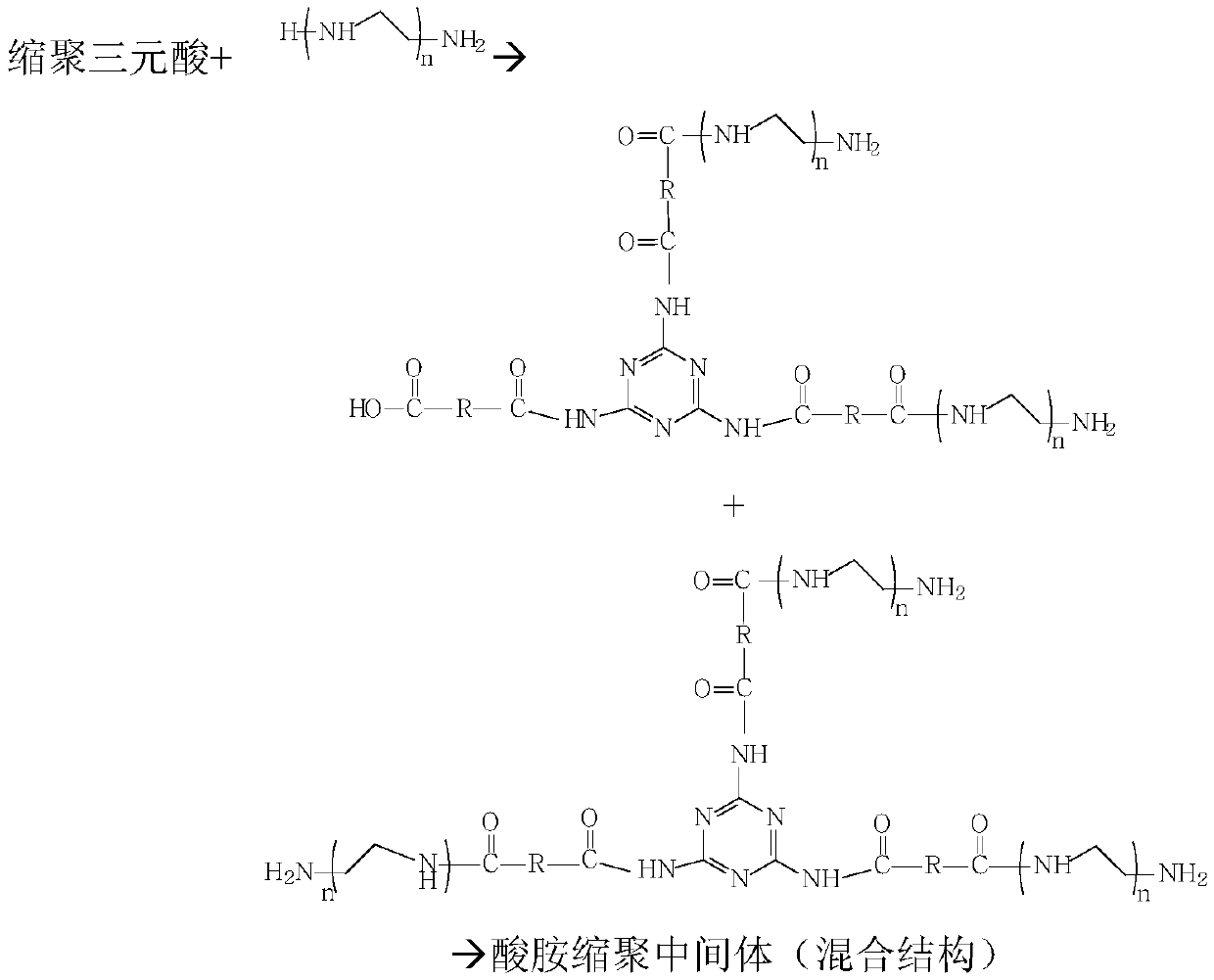

[0026] (2) Add 200g of diethylenetriamine to the above-mentioned tribasic acid, heat to 170°C and react for 120min, and cool to 60°C to obtain an acid amine polycondensation intermediate;

[0027] (3) Add 800g of water to the above acid amine polycondensation intermediate until dissolved, adjust the pH to 8 with ammonia water, add 190g of epichlorohydrin dropwise at 60°C for 240min, and cool to room temperature to obtain a crosslinking agent solution.

Embodiment 2

[0029] With embodiment 1, wherein replace 200g diethylene triamine with 280g triethylene tetramine.

Embodiment 3

[0031] With embodiment 1, wherein replace 350 gram adipic acids with 250 g malonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com