Water-based unsaturated polyester as well as preparation method and application thereof

An unsaturated, water-based technology, used in polyester coatings, coatings, anti-corrosion coatings, etc., can solve problems such as failure to meet green environmental protection requirements, low biomass content, poor flexibility, etc. The effect of comprehensive performance and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

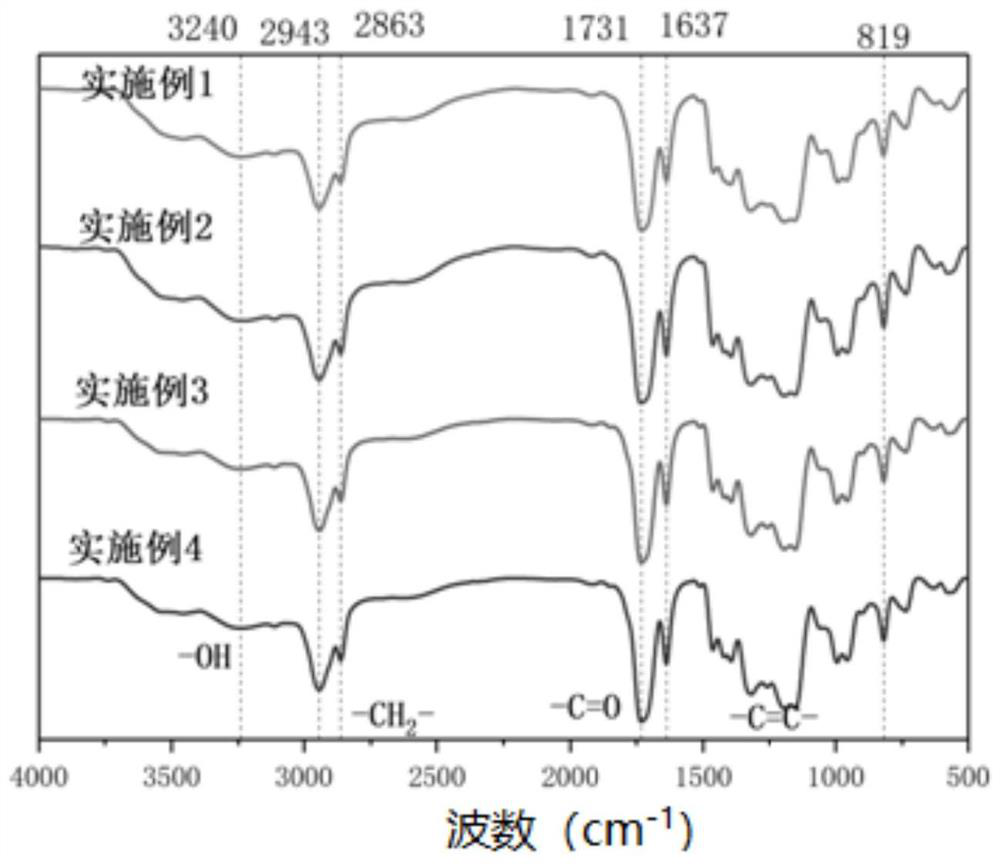

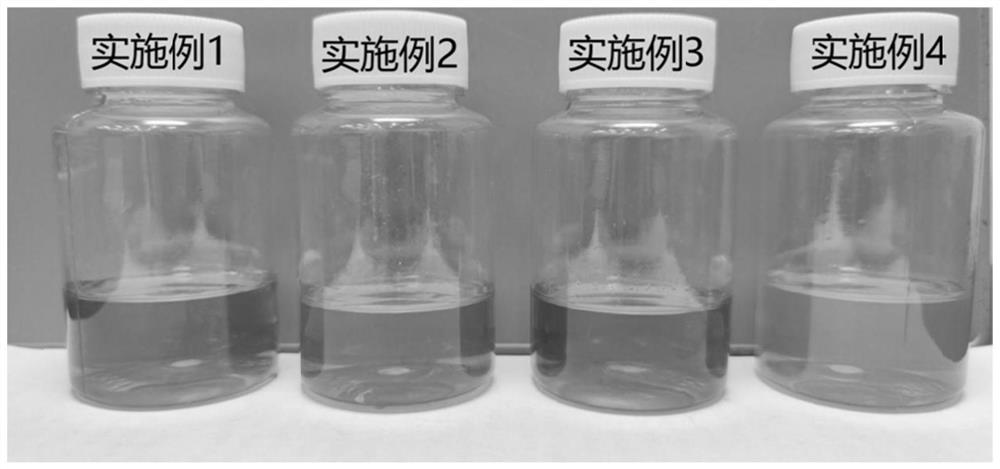

Embodiment 1

[0055] (1) Weigh 11.817g of 1,6-hexanediol, 2.306g of citric acid and 14.051g of itaconic acid into a 250ml four-neck flask, and add 0.103g of p-toluenesulfonic acid and 0.141g of p-hydroxybenzoic acid The ether was connected with a water separator, a stirrer and a circulating condensing device, and the temperature was raised to 140° C. under the protection of nitrogen and vigorously stirred for 5 hours to carry out the esterification reaction.

[0056] (2) After the esterification reaction, 0.141 g of dibutyltin dilaurate was weighed and added into the reactor, the pressure was reduced to -0.095Mpa and the polycondensation reaction was carried out at 140° C. for 2 hours.

[0057] (3) After the polycondensation reaction, cool to 50°C, add triethylamine according to the calculated acid value, make the pH of the target product 7, add an appropriate amount of water to adjust the solid content of the product to 50%, and stir vigorously for 1 h. Finally, photoinitiator 1173 was add...

Embodiment 2

[0059] (1) Weigh 11.817g of 1,6-hexanediol, 3.458g of citric acid and 13.270g of itaconic acid into a 250ml four-necked flask, and add 0.103g of p-toluenesulfonic acid and 0.143g of p-hydroxybenzoic acid The ether was connected with a water separator, a stirrer and a circulating condensing device, and the temperature was raised to 140° C. under the protection of nitrogen and vigorously stirred for 5 hours to carry out the esterification reaction.

[0060] (2) After the esterification reaction, 0.143g of dibutyltin dilaurate was weighed and added into the reactor, the pressure was reduced to -0.095Mpa and the polycondensation reaction was carried out at 140°C for 2h.

[0061] (3) After the polycondensation reaction, cool to 50°C, add triethylamine according to the calculated acid value, make the pH of the target product 7, add an appropriate amount of water to adjust the solid content of the product to 50%, and stir vigorously for 1 h. Finally, photoinitiator 1173 was added and...

Embodiment 3

[0063] (1) Weigh 11.817g of 1,6-hexanediol, 4.035g of citric acid and 12.880g of itaconic acid into a 250ml four-necked flask, and add 0.103g of p-toluenesulfonic acid and 0.144g of p-hydroxybenzoic acid The ether was connected with a water separator, a stirrer and a circulating condensing device, and the temperature was raised to 140° C. under the protection of nitrogen and vigorously stirred for 5 hours to carry out the esterification reaction.

[0064] (2) After the esterification reaction, 0.144g of dibutyltin dilaurate was weighed and added into the reactor, the pressure was reduced to -0.095Mpa and the polycondensation reaction was carried out at 140°C for 2h.

[0065] (3) After the polycondensation reaction, cool to 50°C, add triethylamine according to the calculated acid value, make the pH of the target product 7, add an appropriate amount of water to adjust the solid content of the product to 50%, and stir vigorously for 1 h. Finally, photoinitiator 1173 was added and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com