Silicon-containing waterborne UV bio-based unsaturated polyester and preparation method thereof

A bio-based, unsaturated technology, applied in the field of coatings, can solve the problems of easy agglomeration of inorganic nanoparticles, uneven performance, poor weather resistance, etc., to achieve the effect of light yellow and clear appearance, relieve consumption pressure, and improve comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

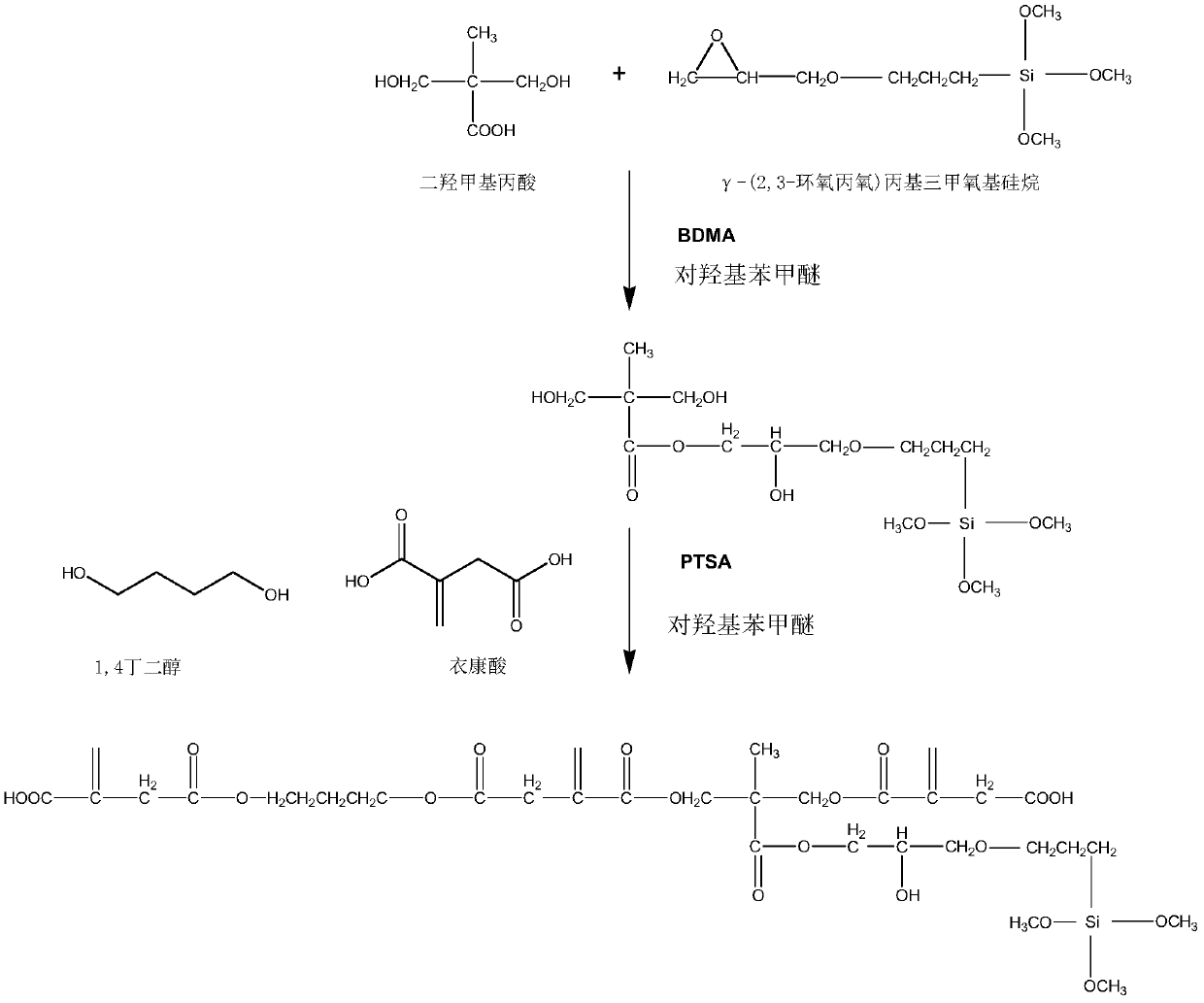

Method used

Image

Examples

Embodiment 1

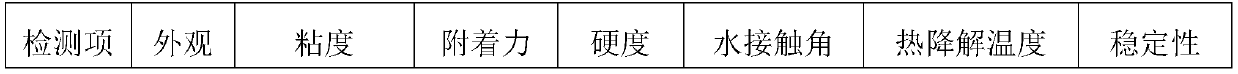

[0041] (1) Weigh 8.56g of 1,4-butanediol and 0.67g of 2,2-dimethylol propionic acid, add them into a four-necked flask equipped with a circulating condensing device, raise the temperature to 60°C, and stir evenly until 2,2 The dimethylolpropionic acid was dissolved, and the solution in the flask was clarified;

[0042](2) Heat up to 90°C, weigh KH560 with the same molar mass as 2,2 dimethylolpropionic acid in a beaker, with a mass of 1.18g, and simultaneously weigh 0.02g of N,N dimethylolamine and p-hydroxyl Anisole 0.02g, stirred and mixed with KH560 evenly, then KH560 mixed with catalyst and polymerization inhibitor was slowly added dropwise into the four-necked flask in four batches on average, each batch was added dropwise within 8 minutes, and the interval between 10 minutes and Add the next batch, and after all the drops are completed, keep the temperature for 1.5h until the acid value drops to 30mg(KOH) / g;

[0043] (3) Raise the temperature to 135°C, blow nitrogen, wei...

Embodiment 2

[0049] (1) Weigh 8.11g of 1,4-butanediol and 1.34g of 2,2-dimethylol propionic acid into a four-necked flask equipped with a circulating condensing device, heat up to 60°C, and stir evenly until 2,2 The hydroxymethylpropionic acid was dissolved, and the flask solution was clarified;

[0050] (2) Heat up to 90°C, weigh KH560 with the same molar mass as 2,2 dimethylolpropionic acid in a beaker, with a mass of 2.36g, and simultaneously weigh 0.03g of N,N dimethylol amine and p-hydroxyl Anisole 0.03g, stir and mix with KH560 evenly, then slowly add KH560 mixed with catalyst and polymerization inhibitor into the four-necked flask dropwise in four batches, each batch is added within 8 minutes, and the next batch is added at an interval of 12 minutes. One batch, after all the drops are completed, keep the temperature for 1.5h until the acid value drops to 30mg(KOH) / g;

[0051] (3) Raise the temperature to 135°C, blow nitrogen, weigh 16.39g of itaconic acid, 0.24g of p-toluenesulfoni...

Embodiment 3

[0056] (1) Weigh 7.21g of 1,4-butanediol and 2.68g of 2,2-dimethylol propionic acid, add them into a four-neck flask equipped with a circulating condensing device, raise the temperature to 60°C, and stir evenly until 2,2 The dimethylolpropionic acid was dissolved, and the solution in the flask was clarified;

[0057] (2) Heat up to 90°C, weigh KH560 with the same molar mass as 2,2 dimethylolpropionic acid in a beaker, with a mass of 4.72g, and simultaneously weigh 0.07g of N,N dimethylol amine and p-hydroxyl Anisole 0.07g, stir and mix with KH560 evenly, then slowly add KH560 mixed with catalyst and polymerization inhibitor into the four-necked flask dropwise in four batches, each batch is added within 8 minutes, and then added at intervals of 15 minutes One batch, after all the drops are completed, keep the temperature for 1.5h until the acid value drops to 30mg(KOH) / g;

[0058] (3) Raise the temperature to 135°C, pass nitrogen gas, weigh 17.17g of itaconic acid, 0.27g of p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com