Rosin polyether glycol used for flame-retardant hard polyurethane foaming plastic and preparation method thereof

A technology of rigid polyurethane and foam plastics, applied in the chemical modification of natural resins, etc., can solve the problems of foaming equipment such as corrosion, instability, and high price, and achieve the effects of wide application prospects, good compressive strength, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

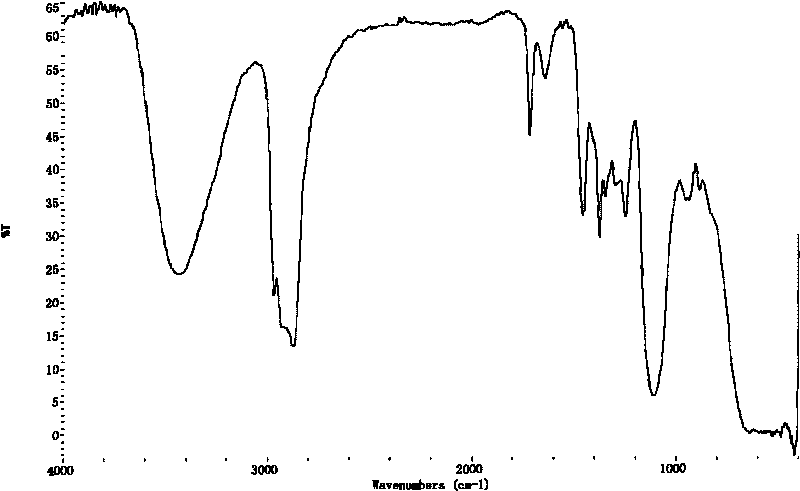

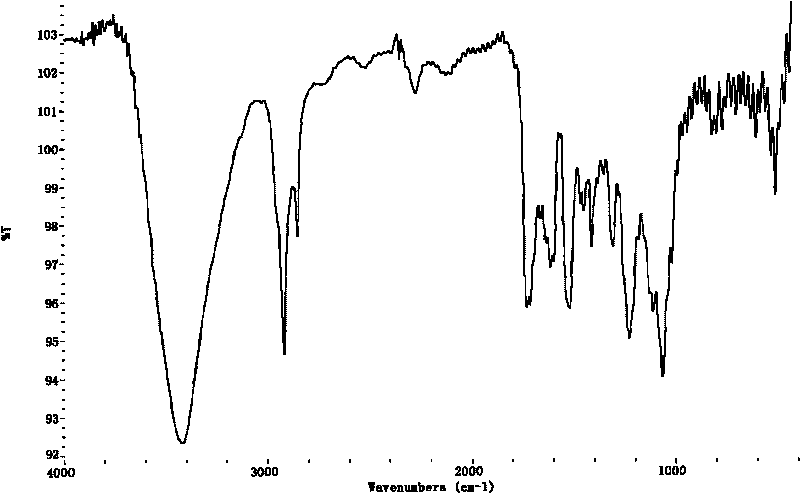

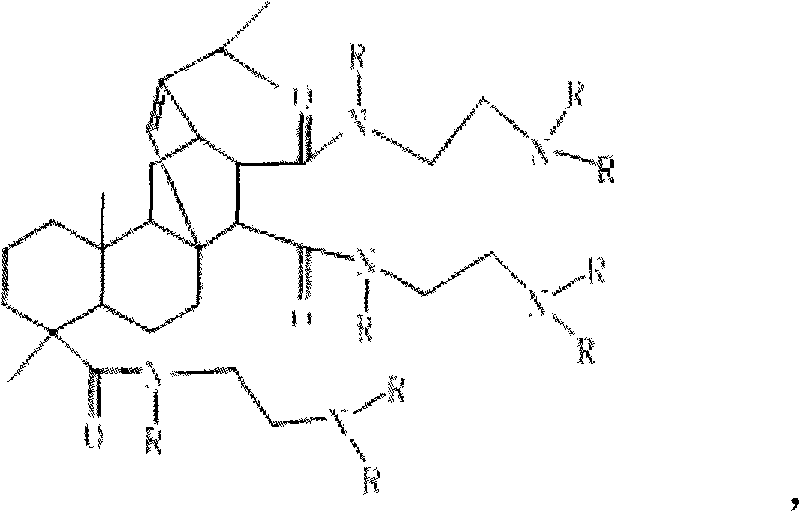

Method used

Image

Examples

Embodiment 1

[0034] Add 400 parts of maleopimaric acid, 150 parts of ethylenediamine, and 5 parts of p-toluenesulfonic acid into a pressure-resistant reactor, mix and heat up and stir, at 180°C, keep the pressure at 0.4Mpa, react for 6 hours, cool down to 100°C, add 1 part KOH, evacuated N 2 The gas is replaced 3 times, the temperature is raised to 150°C, and 500 parts of ethylene oxide and 500 parts of propylene oxide are alternately circulated in equal amounts, that is, a part of ethylene oxide is first passed in for a period of time, and then the same amount of ethylene oxide is passed in. The quality of propylene oxide is passed in alternately like this until all the reactions are completed. React at a reaction temperature of 150°C and a reaction pressure of 1.0 MPa. When ethylene oxide and propylene oxide are circulated in an equal amount, after passing through the epoxide each time, the reaction is constant for 60 minutes. After passing through the epoxide, the reaction ends, stop ...

Embodiment 2

[0038] Add 450 parts of maleopimaric acid, 200 parts of ethylenediamine, and 2 parts of sulfuric acid into a pressure-resistant reactor, mix and heat up and stir, at 170°C, keep the pressure at 0.8Mpa, react for 4 hours, cool down to 110°C, and add 1 part of KOH , vacuum N 2 The gas was replaced 3 times, the temperature was raised to 150°C, and 300 parts of ethylene oxide and 400 parts of propylene oxide were circulated in equal amounts. React at a reaction temperature of 140°C and a reaction pressure of 0.8MP. When ethylene oxide and propylene oxide are circulated in an equal amount, after passing through the epoxide each time, the reaction is constant for 60 minutes. After passing through the epoxide, the reaction ends. Stop responding. emptying. At 120° C. / 10 mm Hg, depressurize and evacuate for 30 minutes to obtain a flame-retardant rosin polyether polyol. Then obtain combined polyol according to the preparation formula of rigid polyurethane foam in Table 1, stir at h...

Embodiment 3

[0040] Add 480 parts of maleopimaric anhydride, 250 parts of urea, and 4 parts of phosphoric acid into a pressure-resistant reactor, mix and heat up and stir, at 160°C, keep the pressure at 0.3Mpa, react for 7 hours, cool down to 120°C, and add 3 parts of potassium methylate, Vacuum N 2 The gas was replaced three times, the temperature was raised to 140°C, and 100 parts of ethylene oxide and 300 parts of propylene oxide were circulated in equal amounts. React at a reaction temperature of 140°C and a reaction pressure of 0.5MP. When ethylene oxide and propylene oxide are circulated in an equal amount, after passing through the epoxide each time, the reaction is constant for 60 minutes. After passing through the epoxide, the reaction ends. Stop responding. emptying. At 120° C. / 10 mm Hg, depressurize and evacuate for 30 minutes to obtain a flame-retardant rosin polyether polyol. Then obtain combined polyol according to the preparation formula of rigid polyurethane foam in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com