Dual UV curable peelable coating and preparation method thereof

A strippable and dual technology, applied in the field of double UV curing strippable coatings and its preparation, can solve the problems of easy rust on the metal surface, long drying time, and restrictions on popularization and application, and achieve short drying time, easy control, and technical mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

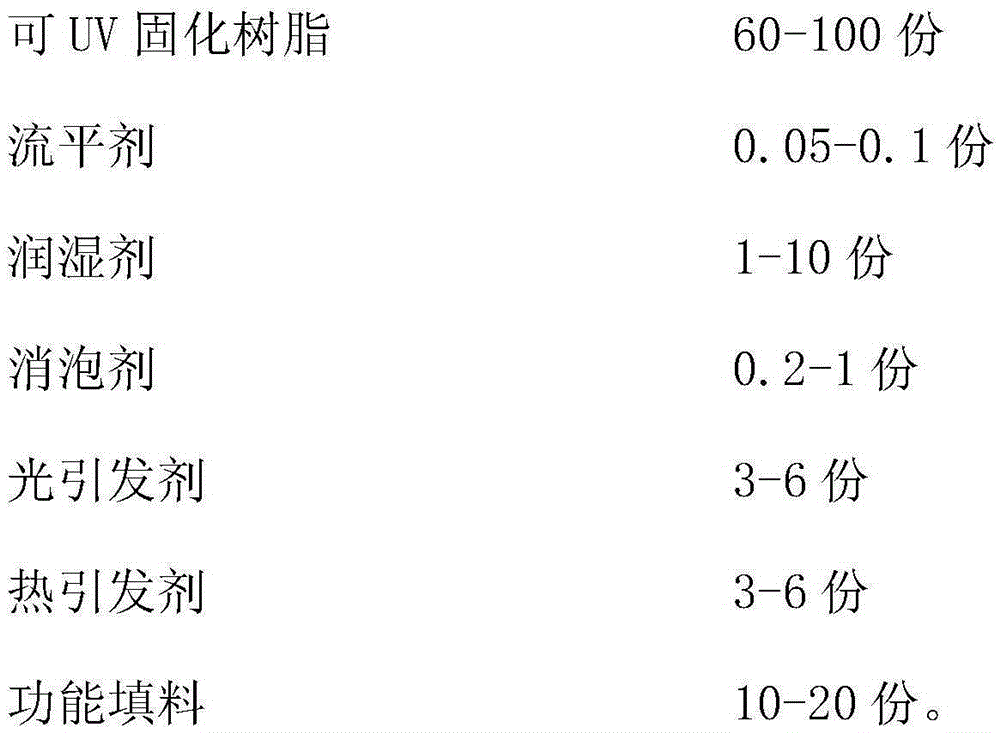

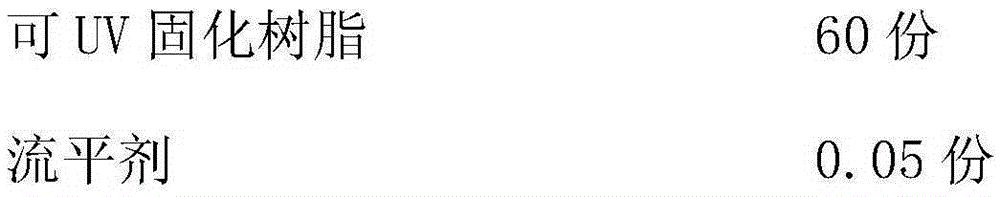

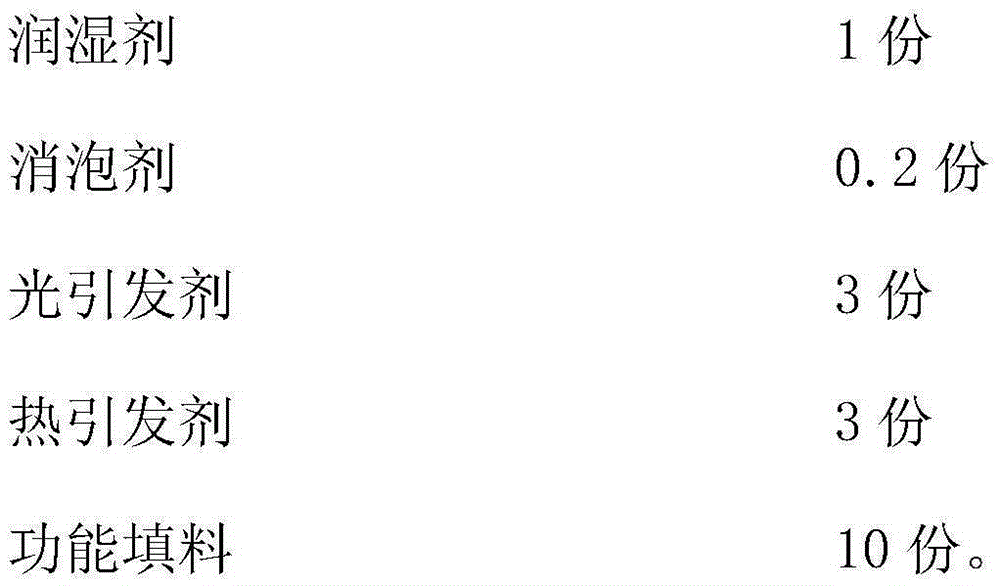

[0038] A double UV curing peelable coating, calculated in parts by weight, its raw material composition and content are as follows:

[0039]

[0040]

[0041] Wherein, the UV curable resin is epoxy acrylate;

[0042] The photoinitiator is a mixture of BASF Irgacure184D and IrgacureTPO in a mass ratio of 1:1;

[0043] The thermal initiator is azobisisobutyronitrile;

[0044] The leveling agent is a mixture of German BYK-345 and BYK-346 in a mass ratio of 1:1;

[0045] Described wetting agent is the NP-100 of U.S. Dow Company;

[0046] Described defoamer is the NopcoNXZ of German Henkel Company;

[0047] The functional filler is mica;

[0048] The above-mentioned preparation method of a kind of double UV curing peelable coating specifically comprises the following steps: according to the formula, add 0.5 part of wetting agent, 0.1 part of Defoamer, 10 parts of functional filler, after dispersing at 1600r / min for 30min, reduce the speed to 300r / min, add 60 parts of UV ...

Embodiment 2

[0053] A double UV curing peelable coating, calculated in parts by weight, its raw material composition and content are as follows:

[0054]

[0055] Wherein, the mixture of the UV curable resin epoxy acrylate and polyurethane acrylate in a mass ratio of 1:1;

[0056] The photoinitiator is one or more mixtures of BASF Irgacure1173 and Irgacure184D in a mass ratio of 1:1;

[0057] Described thermal initiator is dibenzoyl peroxide;

[0058] The leveling agent is Germany BYK BYK-341;

[0059] Described wetting agent is the NP-100 of U.S. Dow Company;

[0060] Described defoamer is the NopcoNXZ of German Henkel Company;

[0061] The functional filler is mica.

[0062] The above-mentioned preparation method of a kind of double UV curing peelable coating specifically comprises the following steps: according to the formula, add 5 parts of wetting agent, 0.5 part of Defoamer, 20 parts of functional filler, after dispersing at 2800r / min for 50min, reduce the speed to 300r / min, ...

Embodiment 3

[0067] A double UV curing peelable coating, calculated in parts by weight, its raw material composition and content are as follows:

[0068]

[0069]

[0070] The preparation method of the double UV curing peelable coating specifically includes the following steps: according to the formula, add 3 parts of wetting agent and 0.3 part of defoamer to the GFJ-0.4 high-speed disperser (Shanghai Xinnuo Instrument Equipment Co., Ltd.) 16 parts of functional fillers, after dispersing at 2000r / min for 40min, reduce the speed to 300r / min, add 80 parts of UV curable resin and the remaining 0.3 parts of defoamer, 3 parts of wetting agent and 0.08 parts of leveling Agent, 5 parts of photoinitiator, 5 parts of thermal initiator, and stir evenly, continue to disperse for 7 minutes, after mixing evenly, filter through GS450 small vibrating sieve (Laizhou Jingtai Chemical Machinery Factory) to remove the filter residue, and obtain double UV curing strippability coating.

[0071] In summa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com