Pneumatic tongs

A pneumatic clamp and cylinder technology, applied in the field of clamps, can solve the problems of cylinder inner wall and piston rust, piston and cylinder partial wear, low connection strength, etc., and achieve the effect of small installation space, large connection surface and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

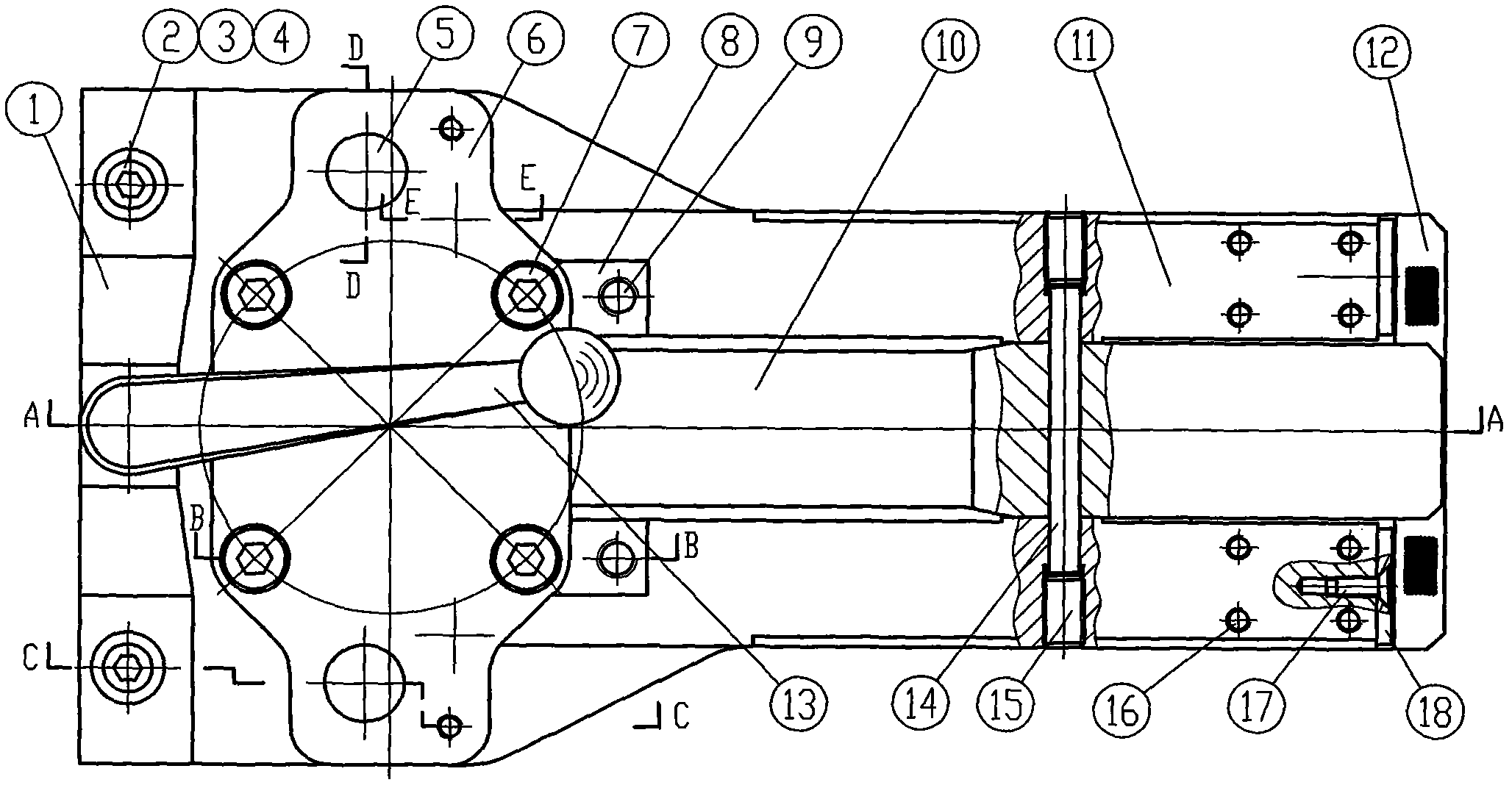

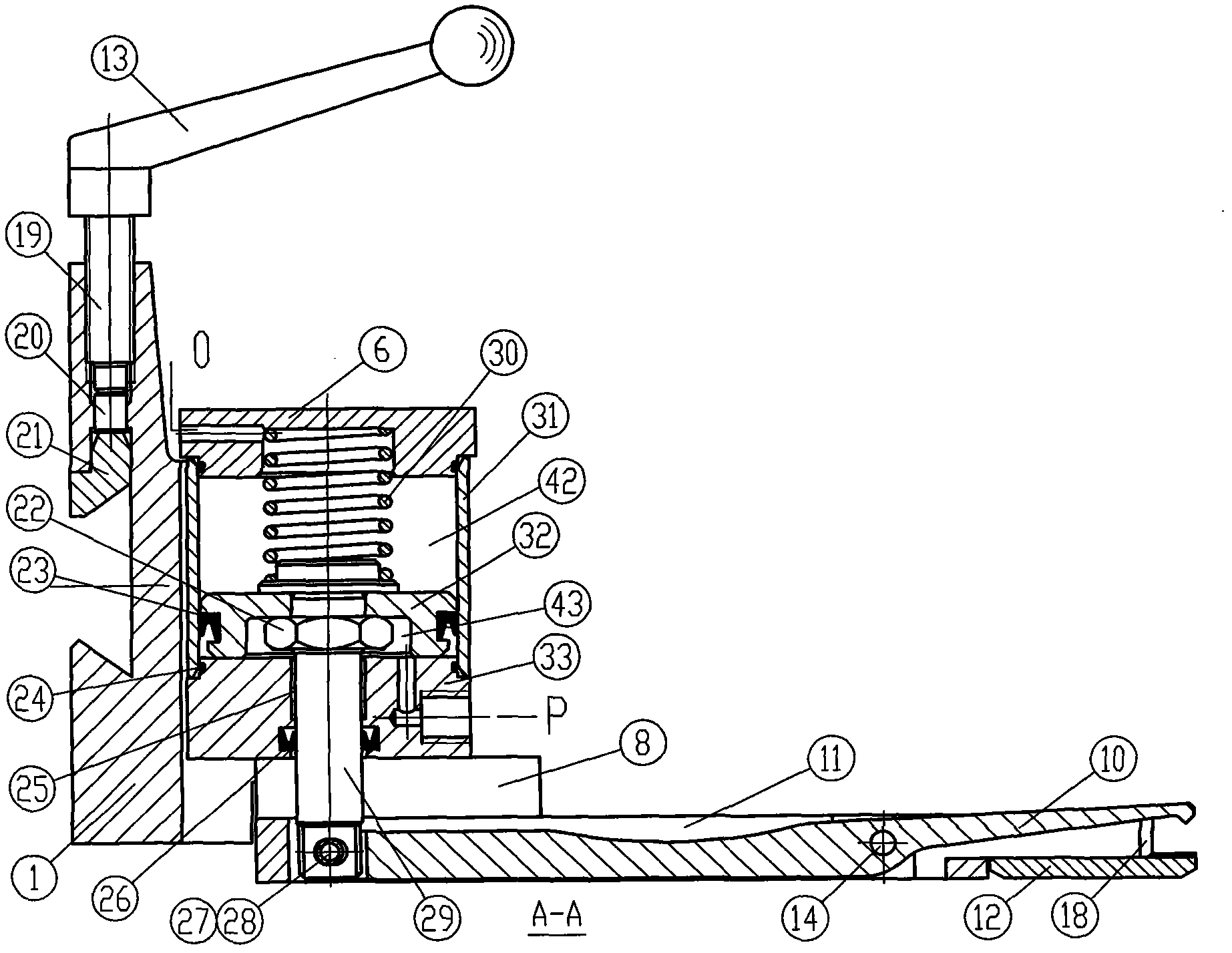

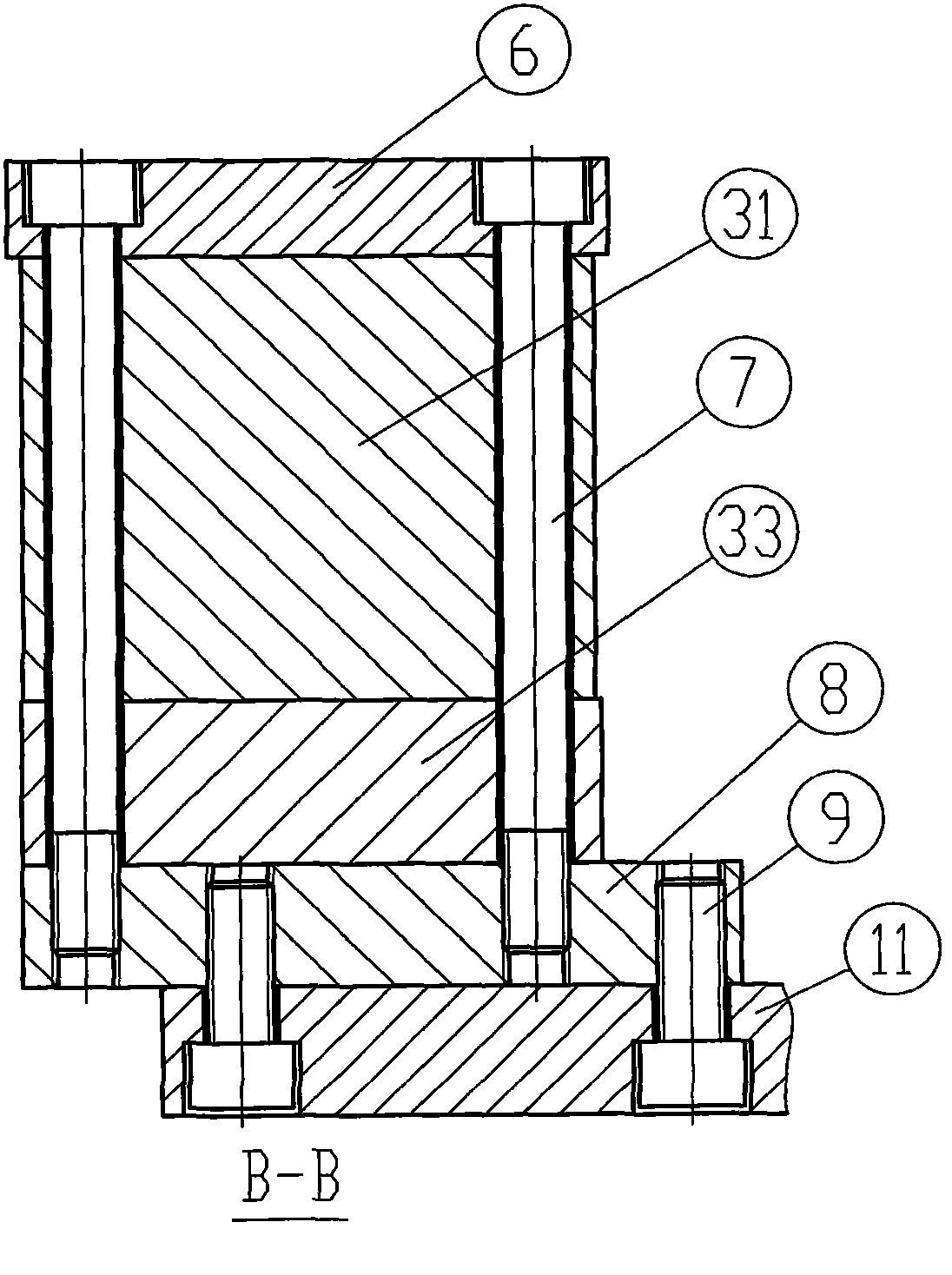

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a pneumatic clamp is composed of a base 1, a cylinder, an upper clamp body 10, a lower clamp body 11, etc., and the cylinder is composed of a cylinder head 6, a piston rod 29, a cylinder barrel 32, a piston 33, and a cylinder seat 34, back-moving spring 31 etc. constitute. The middle part of the upper caliper body is hingedly connected with the lower caliper body through pin shaft 14, and the rear end of the upper plier body is connected with the piston rod tail end of the cylinder through pin shaft 27. The cylinder head, cylinder barrel and cylinder seat of the cylinder are connected with four bolts 7, 4 A bolt 9 is fastened on the lower tong body through two contour pads 8, and two sliding posts 5 are arranged in series on the cylinder head, the lower tong body and the base, and two straight lines are arranged in the base hole through which the sliding posts pass. bearing37. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com