Defrosting heater of refrigerator

A technology for defrosting heaters and refrigerators, which is applied to defrosting, lighting and heating equipment, household appliances, etc., and can solve the problems of reduced heating efficiency of the heater 20, failure to reach the defrosting capacity point, and increased production costs. Achieve the effect of simple structure, low production cost and good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

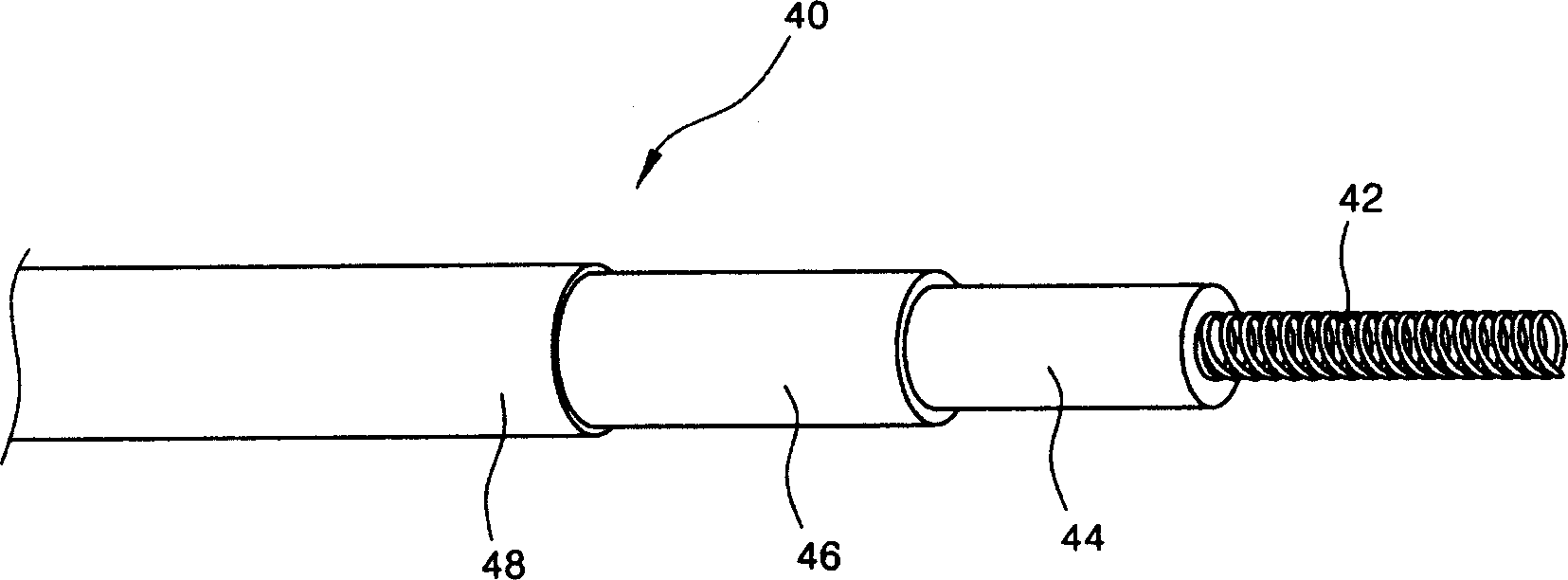

[0030] Such as image 3 As shown, the defrosting heater 40 of the refrigerator in this embodiment includes: an electric heater 42 that generates heat after being energized, an insulating tube 44 that is sleeved outside the heating wire, an outer tube 46 that is sleeved outside the insulating tube 44, and an outer tube 46 formed on the outer surface of the outer tube 46. Ceramic coating48.

[0031] The heating wire 42 generates heat after being energized, and radiates heat to the evaporator to remove frost on the surface of the evaporator. The insulating tube 44 is used to electrically isolate the heating wire 42 from the outside.

[0032] The outer tube 46 is a part that forms the appearance of the heater, and is made of a metal material with high rigidity and good thermal conductivity.

[0033] In this embodiment, the outer pipe 46 is an iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com