A preparation method of a coaxial cable and a microwave absorbing inner sheath of a TTC radar for an aircraft

A technology of coaxial cable and inner sheath is applied in the field of aircraft measurement and control radar coaxial cable, which can solve the problems of increasing installation difficulty and time, affecting attenuation performance, affecting output probability, etc., so as to improve shielding performance and structural performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

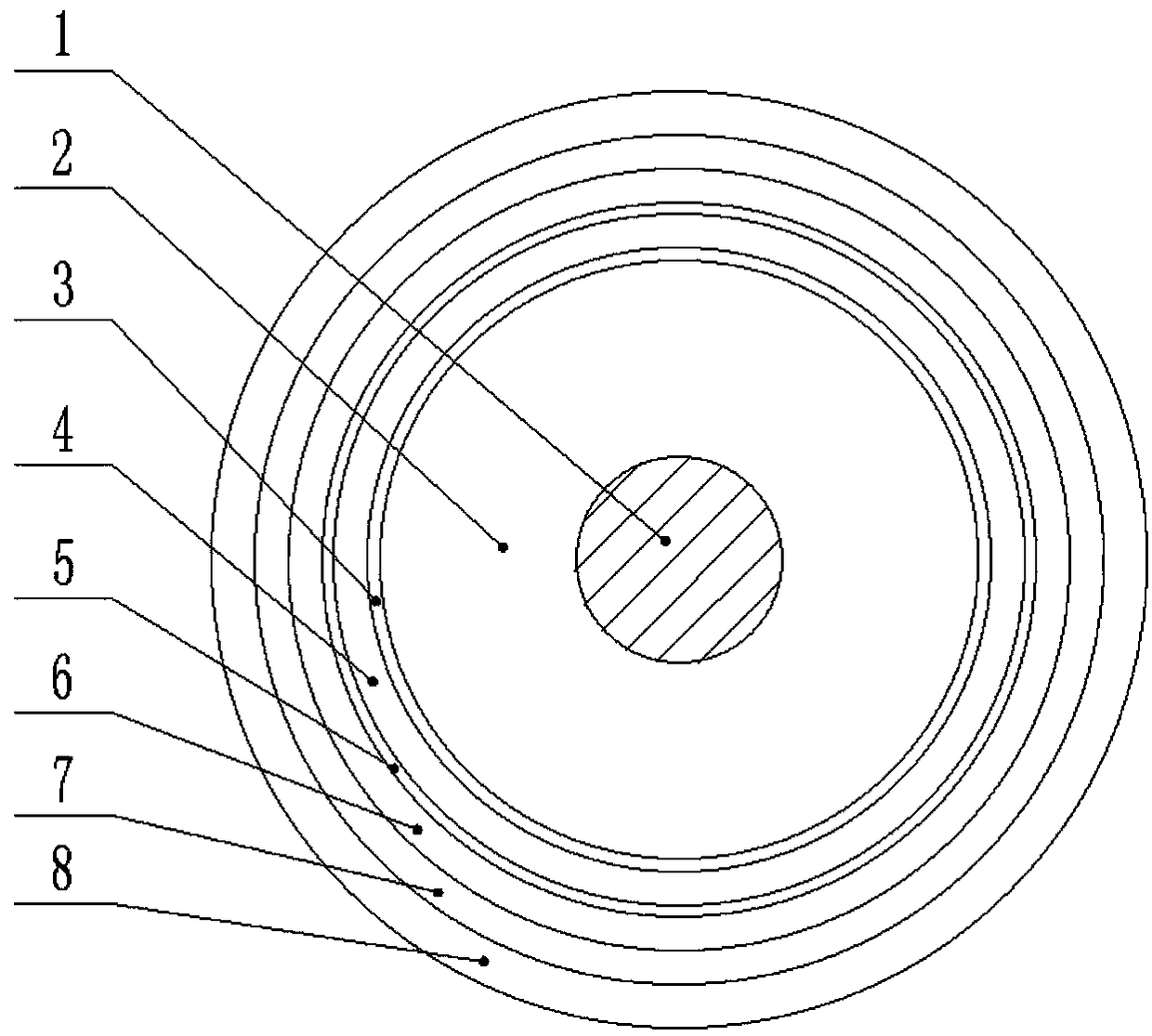

[0042] Embodiment one: if figure 1 As shown, a coaxial cable for aircraft measurement and control radar in this embodiment includes a conductor 1, an insulating layer 2, an aluminum-plastic composite tape shielding layer 3, an inner braided shielding layer 4, and a braided lubricating layer 5 arranged in sequence from the inside to the outside. , outer braided shielding layer 6, inner sheath 7 and outer sheath 8;

[0043] The conductor 1 is twisted by seven first silver-plated copper wires with a nominal diameter of 0.82mm, the thickness of the silver-plated layer of the first silver-plated copper wires is at least 2um, and the outer diameter of the conductor 1 is 2.40mm. The semi-tightening process is used for stranding, which increases the contact surface of each first silver-plated copper wire. From the resistance formula (R=ρ*L / S), it can be concluded that the size of the wire resistance is proportional to the length of the wire, and is proportional to the length of the wi...

Embodiment 2

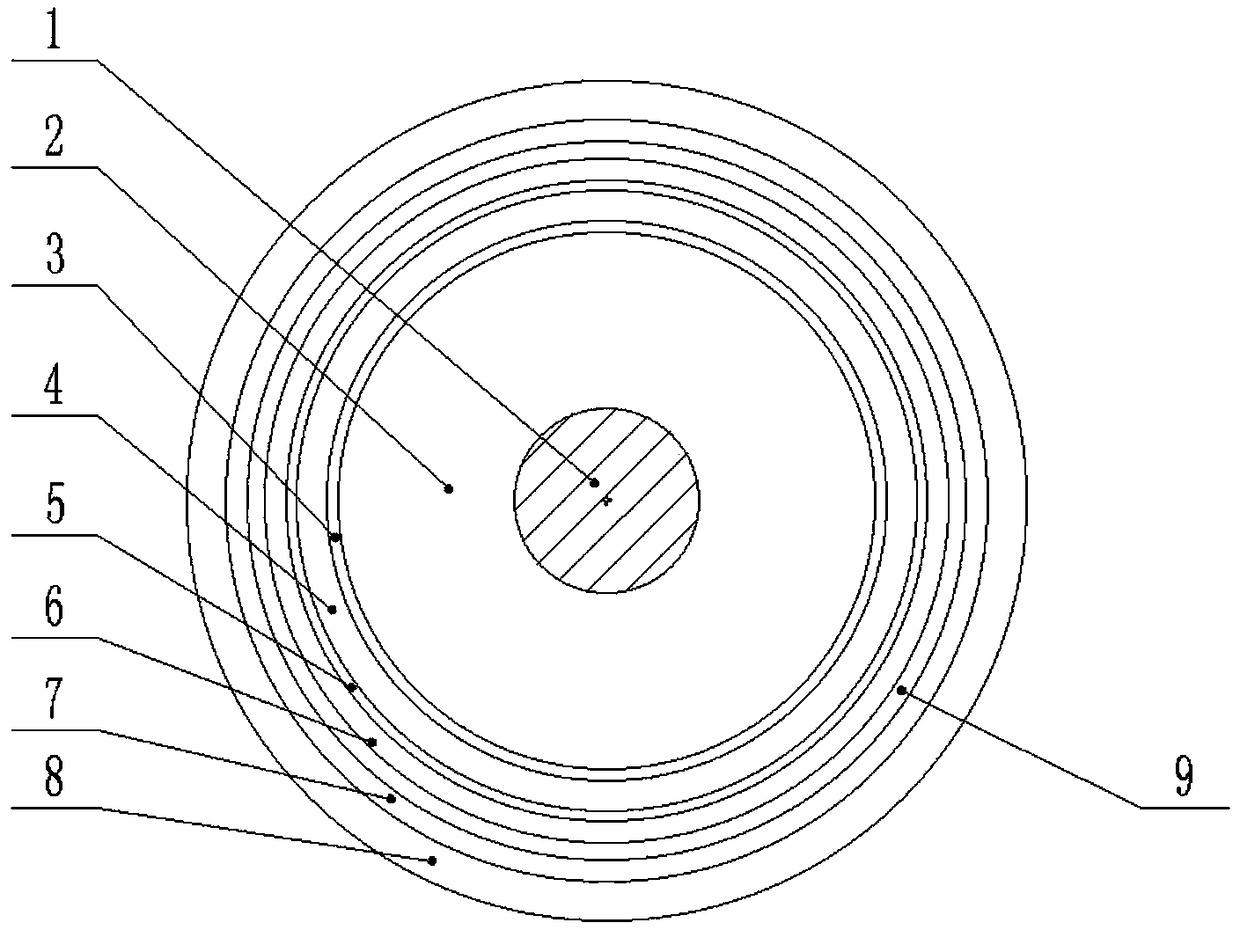

[0051] Embodiment two: if figure 2 As shown, the aircraft measurement and control radar coaxial cable of this embodiment includes a conductor 1, an insulating layer 2, an aluminum-plastic composite tape shielding layer 3, an inner braided shielding layer 4, a braided lubricating layer 5, and an outer braided shielding layer arranged sequentially from the inside to the outside. The braided shielding layer 6, the inner sheath 7 and the outer sheath 8; the semi-compressed process is used for twisting, increasing the contact surface of each first silver-plated copper wire, from the resistance formula (R=ρ*L / S) It can be concluded that the wire resistance is proportional to the length of the wire, inversely proportional to the cross-sectional area of the wire, and related to the resistivity of the material; for the same material and cross-sectional area, the longer the wire, the greater the resistance, and the same material and length, the greater the cross-sectional area. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com