Lubricated hot-dip galvanized steel sheet with excellent viscidity and manufacturing method thereof

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, device for coating liquid on the surface, coating, etc., can solve problems such as poor adaptability of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below with embodiment and accompanying drawing.

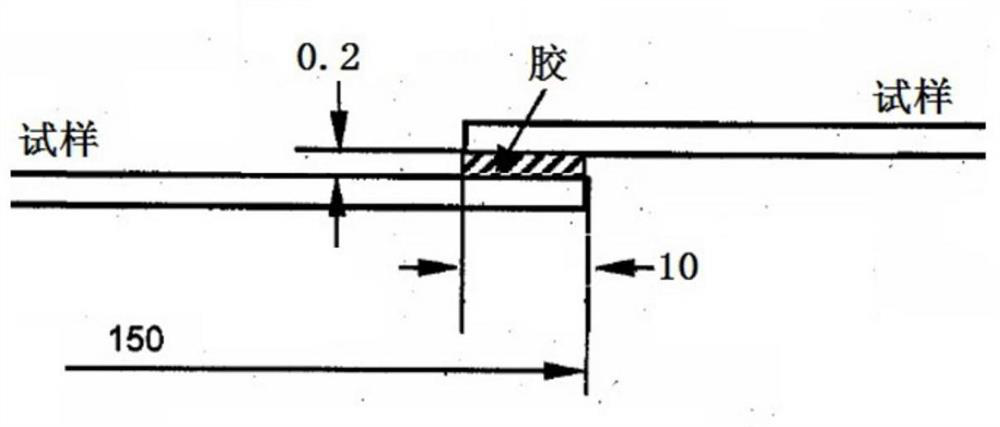

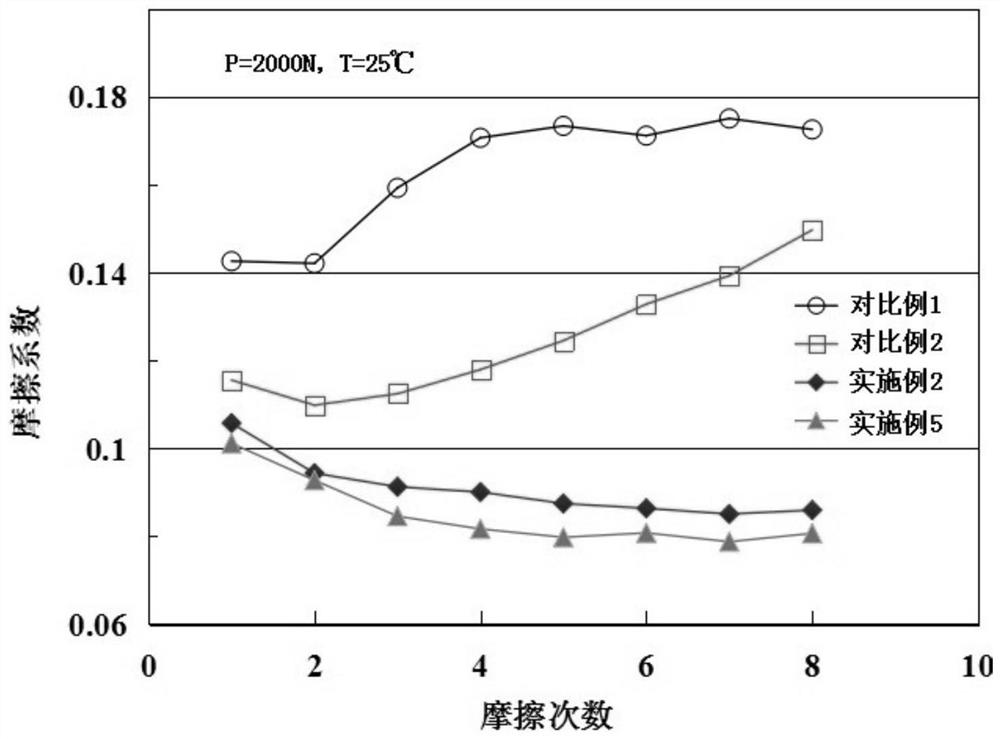

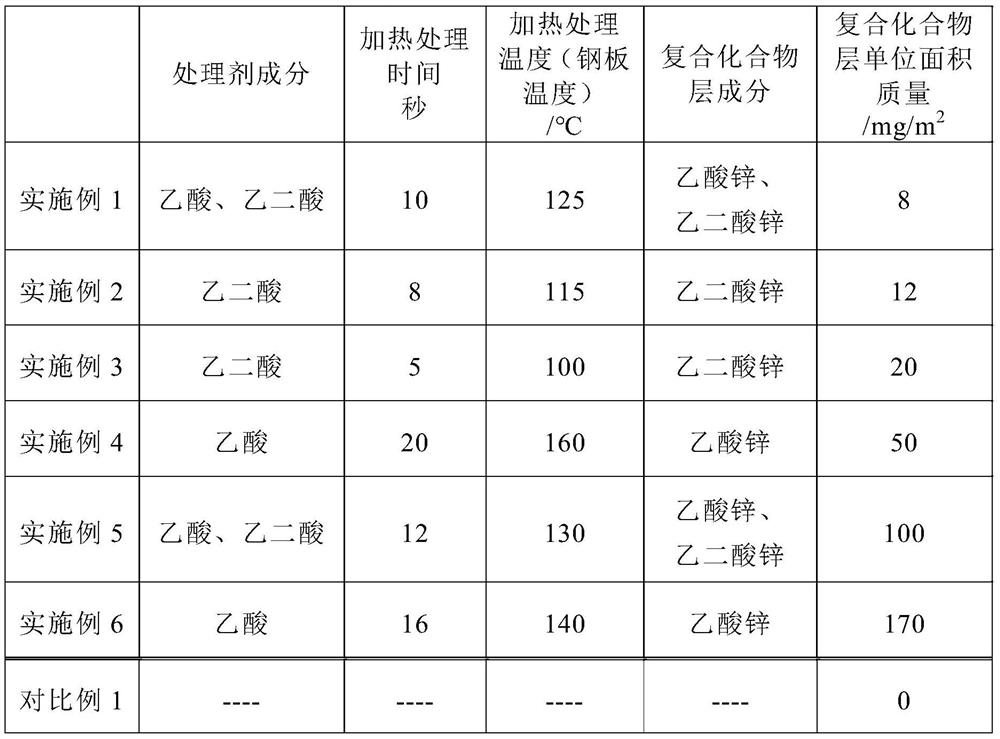

[0034] The cold-rolled IF steel sheet is hot-dip galvanized according to the usual hot-dip galvanizing process to obtain a hot-dip galvanized steel sheet, so that the composition of the coating is (mass percentage): Al 0.1-0.4, the balance Zn and unavoidable impurities, and then pass the leveling The roughness of the surface of the coating is controlled to be 0.6-1.5 μm. At room temperature, the aqueous solution containing acetic acid and oxalic acid is evenly coated on the surface of hot-dip galvanized steel sheet by roller coating method, and then heated by hot air to heat the steel sheet so that the temperature of the steel sheet reaches 100-160 within 5-20 seconds. ℃, a composite compound layer of different weights is formed on the surface of the hot-dip galvanized steel sheet (see Table 1). Then apply an appropriate amount of anti-rust lubricating oil on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com