Ti3SiC2/Al2O3 hybrid reinforcing copper-based composite sliding plate material and preparation method thereof

A copper-based composite, sliding plate technology, used in metal processing equipment, coating, transportation and packaging, etc., can solve the problem of pantograph sliding plate working stability, poor wear resistance performance index, poor impact resistance, poor operational reliability and other problems to achieve the effect of reducing the possibility of forming defects and pits, improving impact resistance and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

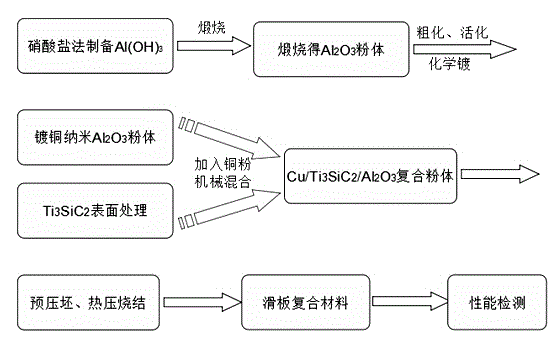

[0043] 1) First prepare nano-copper-plated nano-Al 2 o 3 The wt% ratio is 1%, copper-plated Ti 3 SiC 2 The wt% is 20%, and the rest is copper powder with a particle size of 200 mesh;

[0044] 2) Sequentially weigh 2g of copper-plated nano-Al 2 o 3 Powder, 40g copper-plated Ti 3 SiC 2 The powder and 158g of copper powder are then mixed mechanically, the mixing time is 10h, and the mixing speed is 200rpm. The mixing speed should not be too high to prevent damage to the integrity of the surface coating;

[0045] 3) Use a steel mold of 200MPa to pre-compact, then put the pre-compact into a graphite mold with an inner diameter of 70mm, and carry out vacuum hot-press sintering. During hot-press sintering, the temperature is raised at a speed of 15°C / min, and the sintering temperature is 800°C , the sintering pressure is 25MPa, and the sintering time is controlled at 1h;

[0046] 4) Use an extrusion die with a die size of 28*38 for hot extrusion molding. Strictly control the ...

Embodiment 2

[0049] 1) First prepare copper-plated nano-Al 2 o 3 The wt% ratio is 3%, copper-plated Ti 3 SiC 2 The wt% is 30%, and the rest is copper powder with a particle size of 200 mesh;

[0050] 2) Weigh 6g of copper-plated nano-Al in sequence 2 o 3 Powder, 60g copper-plated Ti 3 SiC 2 The powder and 134g of copper powder are then mechanically mixed, the mixing time is 10h, and the mixing speed is 200rpm. The mixing speed should not be too high to prevent damage to the integrity of the surface coating;

[0051] 3) Use a steel mold of 250MPa to pre-compact the compact, then put the pre-compact into a graphite mold with an inner diameter of 70mm, and carry out vacuum hot-press sintering. During hot-press sintering, the temperature is raised at a speed of 20°C / min, and the sintering temperature is 850°C , the sintering pressure is 30MPa, and the sintering time is controlled at 1.5h;

[0052] 4) Use an extrusion die with a die size of 28*38 for hot extrusion molding. Strictly cont...

Embodiment 3

[0055] 1) First prepare copper-plated nano-Al 2 o 3 The wt% ratio is 5%, copper-plated Ti 3 SiC 2 The wt% is 40%, and the rest is copper powder with a particle size of 200 mesh;

[0056] 2) Weigh 10g of copper-plated nano-Al in sequence 2 o 3 Powder, 80g copper-plated Ti 3 SiC 2 The powder and 110g of copper powder are then mechanically mixed, the mixing time is 10h, and the mixing speed is 200rpm. The mixing speed should not be too high to prevent damage to the integrity of the surface coating;

[0057] 3) Use a steel mold of 300MPa to pre-compact the compact, and then put the pre-compact into a graphite mold with an inner diameter of 70mm for vacuum hot-press sintering. During hot-press sintering, heat up at a speed of 25°C / min, and the sintering temperature is 900°C , the sintering pressure is 35MPa, and the sintering time is controlled at 2h;

[0058] 4) Use an extrusion die with a die size of 28*38 for hot extrusion molding. Strictly control the extrusion temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com