Electric wheel hub with wheel edge reduction gear

A wheel-side deceleration and electric wheel hub technology, which is applied in the direction of power devices, control devices, motion deposition, etc., can solve the problems of complex structure of gearboxes, low support rigidity, and many casting sand cores, and achieve simple structure, high support rigidity, Effect of Good Lubricating Function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

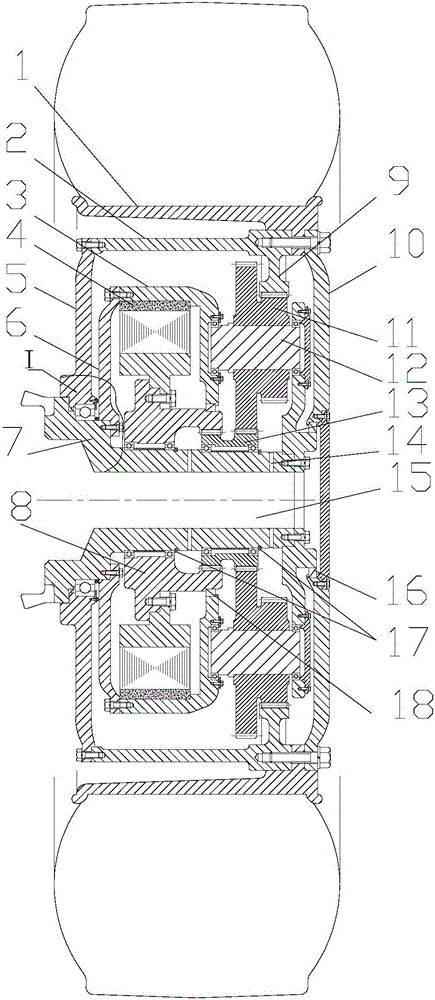

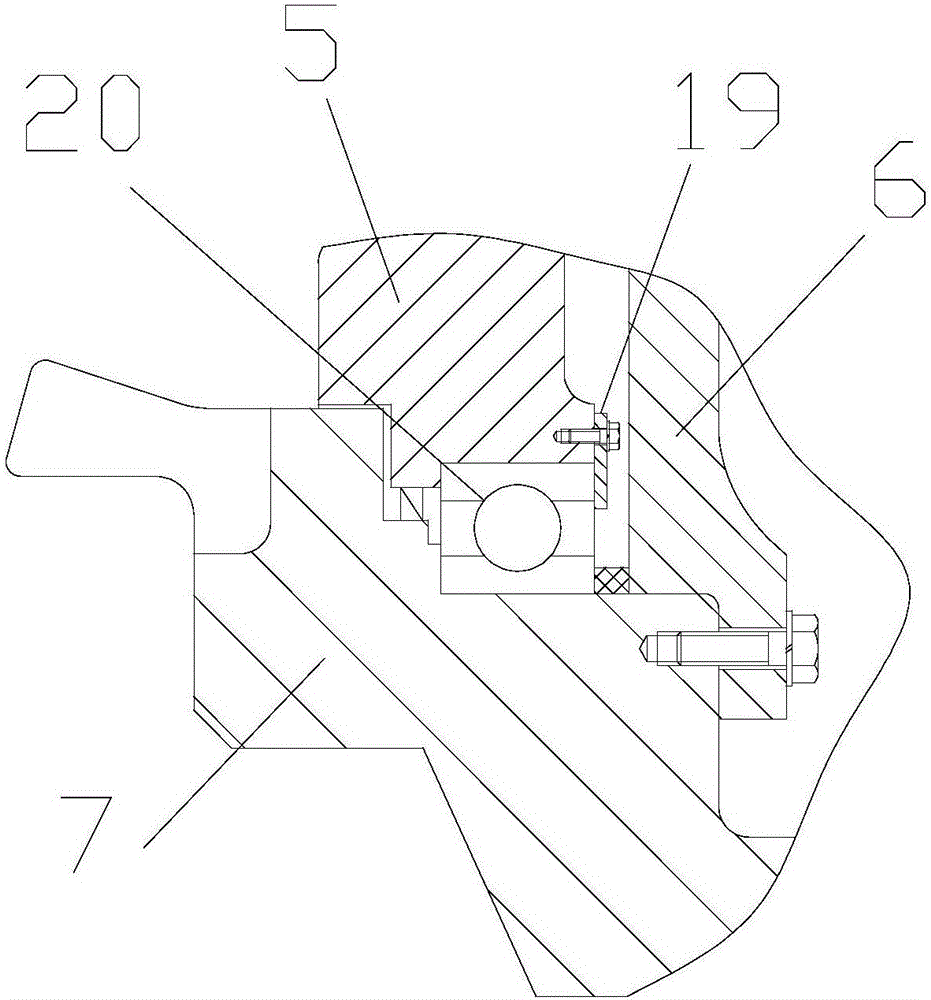

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the electric hub 1 with the wheel side reduction device in this example includes the hub main shaft 7, the hub 1 rotatably fitted on the hub main shaft 7, and the hub 1 The inner hub 1 motor and the wheel side reduction device, the wheel side reduction device includes a central gear 13 that is rotatably fitted to the hub main shaft 7, an inner ring gear 9 that is coaxially fixed with the hub 1 and surrounds the hub main shaft A plurality of dual gears 11 are distributed, and the central gear 13 is used to distribute the power output by the hub motor to the large gear of each dual gear 11, and the pinion gear of each dual gear 11 is meshed with the The inner ring gear 9; the electric hub with the wheel side reduction device in this embodiment, the hub motor transmits the power to the inner ring gear 9 through the central gear 13 and the double gear 11 in turn, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com