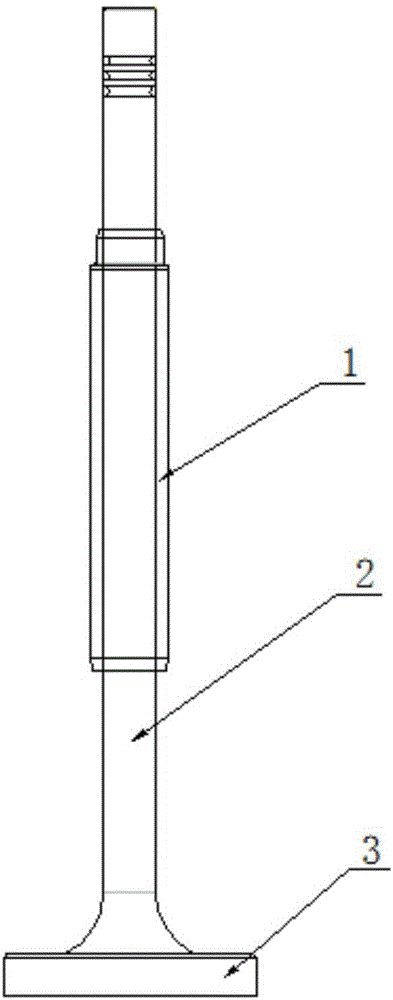

Self-lubricating composite material layer, preparation method and component with self-lubricating function

A composite material layer and self-lubricating technology, which is applied in the field of self-lubricating components, preparation, and self-lubricating composite materials, can solve the problem of intake valve wear failure, high frequency of intake valve failure, and affecting the overall performance of the whole machine And other problems, to achieve good wear resistance, improve the lubrication situation, the effect of excellent lubrication function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

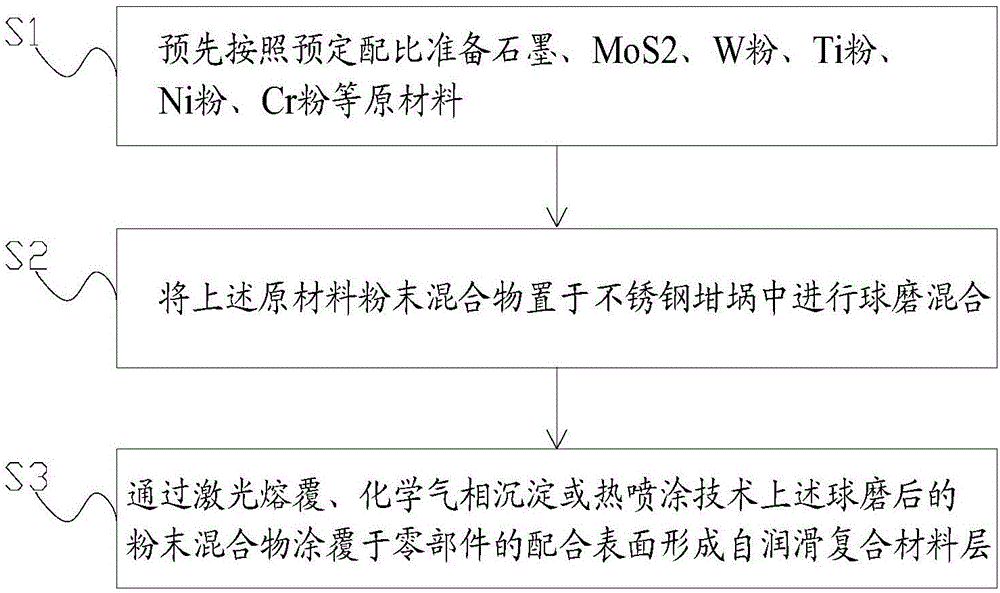

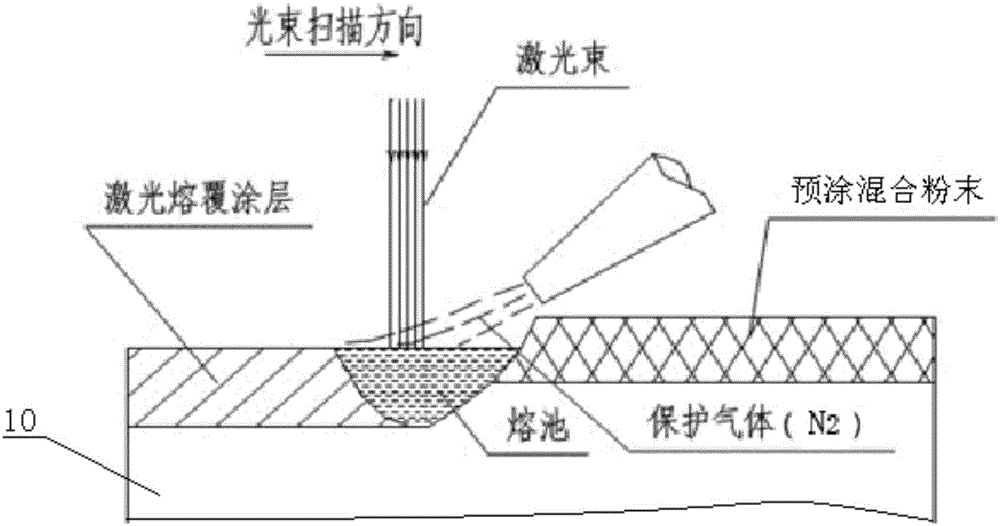

Method used

Image

Examples

Embodiment Construction

[0027] Aiming at the technical problem of intake valve wear and tear mentioned in the background technology, this paper has carried out in-depth research, and found that the main means to solve the intake valve wear in the prior art is to increase the hardness of the intake valve. Although increasing the hardness of the surface material can Improving the wear resistance of the intake valve does not improve the problem of difficult lubrication between the intake valve and the valve seat ring, and the problem of wear between the friction pairs still exists. And the frictional force between metal (intake valve) and metal (valve seat ring) is very big, the surface material of high hardness still can have abrasion, after the high hardness material layer is damaged, intake valve is worn out failure very soon.

[0028] On the basis of the above research findings, this paper conducted further exploration and found that the root cause of the above technical problems in the prior art is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com