Novel diamond abrasive wire cutting fluid

A technology of diamond sand and wire cutting, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problem of high COD value of sewage, and achieve the effects of low COD value, environmental friendliness and obvious lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

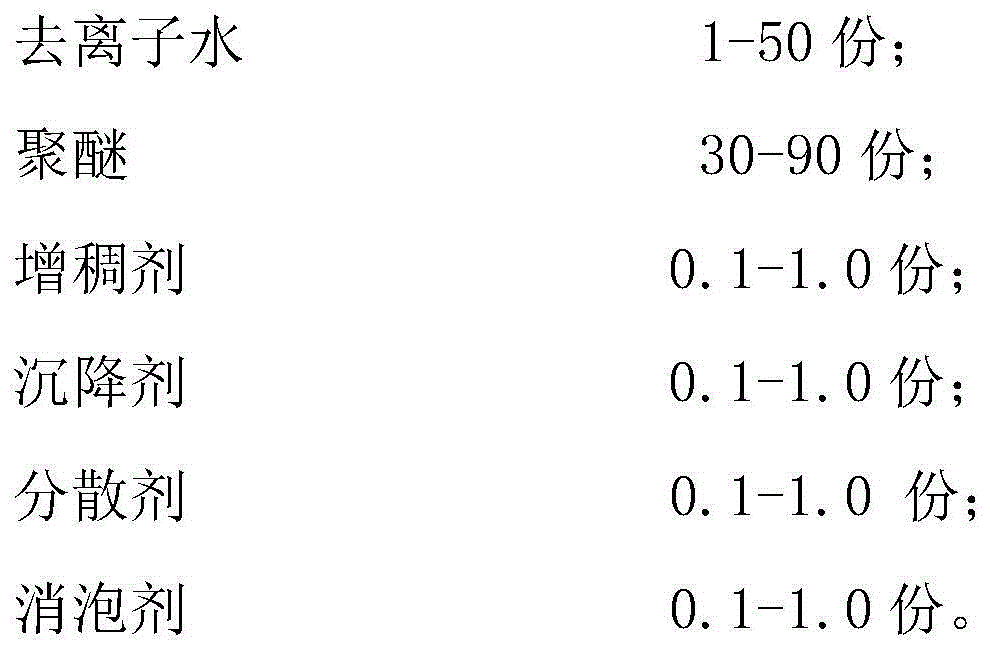

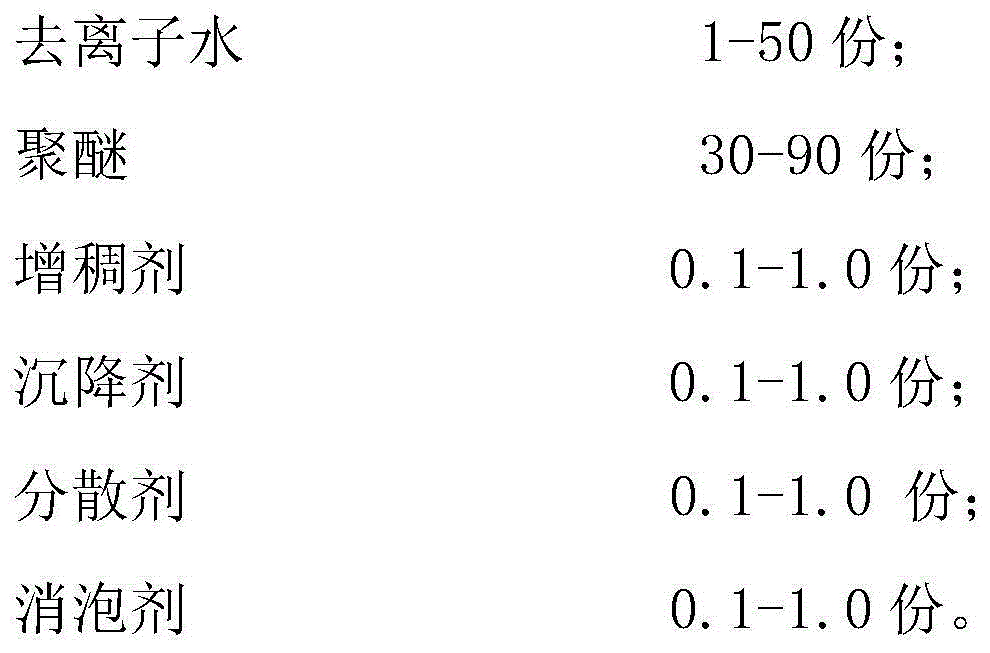

[0022] A kind of novel diamond sand wire cutting liquid, its preparation method comprises the following steps:

[0023] (1) Take 90 parts by weight of polyether; said polyether is made by polyaddition reaction of propylene glycol, ethylene glycol and ethylene oxide;

[0024] (2) Weigh 1 part of deionized water, pour the polyether into the water, stir and dissolve, and prepare the basic solution;

[0025] (3) Weigh 0.1 parts by weight of sodium carboxymethyl cellulose, hydroxyethyl cellulose, starch, gelatin, a mixture of guar gum, 0.1 parts by weight of polyacrylic acid, a mixture of sodium polyacrylate, 0.1 parts by weight of ethylene glycol mono Butyl ether and 0.1 parts by weight of organosiloxane were sequentially added to the base solution obtained in step (2), stirred thoroughly and left to stand for 30 minutes after they were completely dissolved, to obtain a new diamond wire cutting fluid.

Embodiment 2

[0027] A kind of novel diamond sand wire cutting liquid, its preparation method comprises the following steps:

[0028] (1) Take 30 parts by weight of polyether; said polyether is made by polyaddition reaction of glycerol, trimethylolpropane, pentaerythritol and propylene oxide (PO);

[0029] (2) Weigh 10 parts of deionized water, pour the polyether into the water, stir and dissolve, and prepare the basic solution;

[0030] (3) Weigh 0.5 parts by weight of methyl cellulose, hydroxypropyl methyl cellulose, the mixture of sodium carboxymethyl cellulose, 0.5 parts by weight of calcium polyacrylate, alkali hydrolyzate of polyacrylamide, copolymerization of acrylamide The mixture of compound, 1 weight part ethylene glycol monobutyl ether, tridecanol, isopropanol, ether, ethylene glycol, ethanol and 1 weight part organosiloxane, add in the basic solution of step (2) gained successively, Stir fully and let it stand for 30 minutes after it is completely dissolved, and then a new type...

Embodiment 3

[0032] A kind of novel diamond sand wire cutting liquid, its preparation method comprises the following steps:

[0033] (1) Take 50 parts by weight of polyether; said polyether is made by polyaddition reaction of glycerol, trimethylolpropane, pentaerythritol, xylitol, sorbitol, sucrose and butylene oxide (BO);

[0034] (2) Weigh 50 parts of deionized water, pour the polyether into the water, stir and dissolve, and prepare the basic solution;

[0035] (3) Weigh 0.3 parts by weight of chitosan, gum arabic, xanthan gum, soybean protein glue, agar, polyacrylamide, polyvinyl alcohol, polyvinylpyrrolidone, the mixture of polyacrylic acid, 0.6 parts by weight of acrylamide, 0.8 parts by weight The mixture of ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, diethylene glycol butyl ether, tridecyl alcohol, isopropanol, ether, ethylene glycol, ethanol and 0.6 parts by weight of organosiloxane, add step ( 2) In the obtained basic solution, fully stir until it is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com