Aqueous lithium-ion battery, electrode used therein, and electrode manufacturing method

A lithium-ion battery and manufacturing method technology, applied in the direction of electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problems of high cost, expanded working voltage, etc., achieve good stability, prolong cycle life, and suppress production. The effect of the hydrogen reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

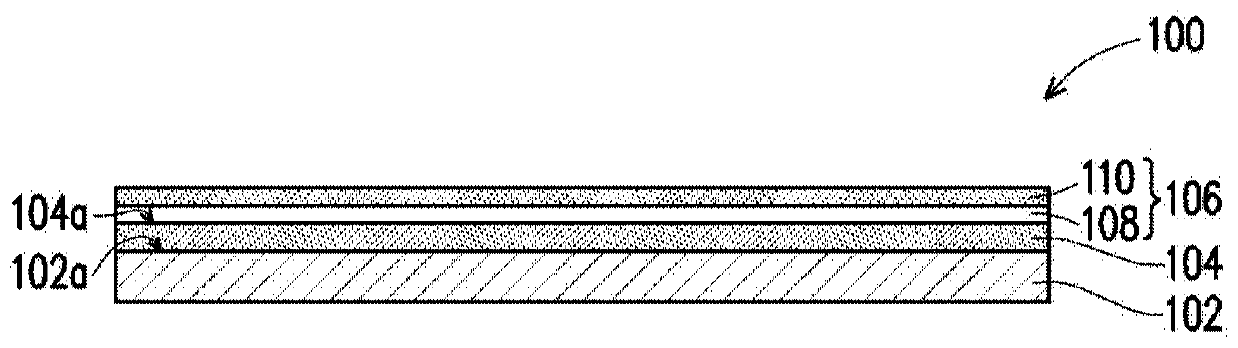

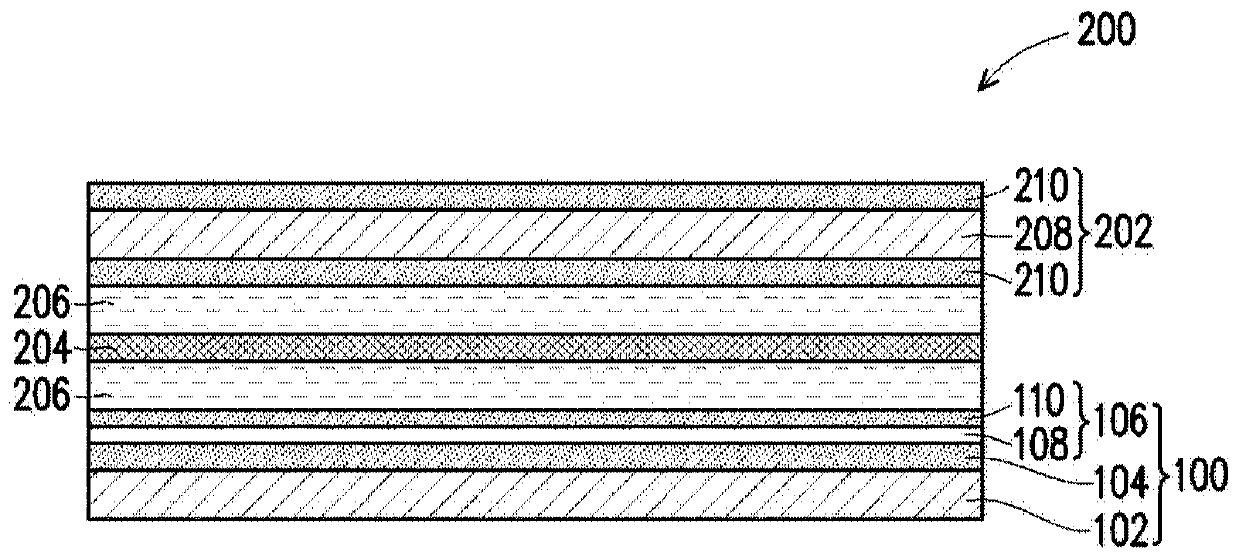

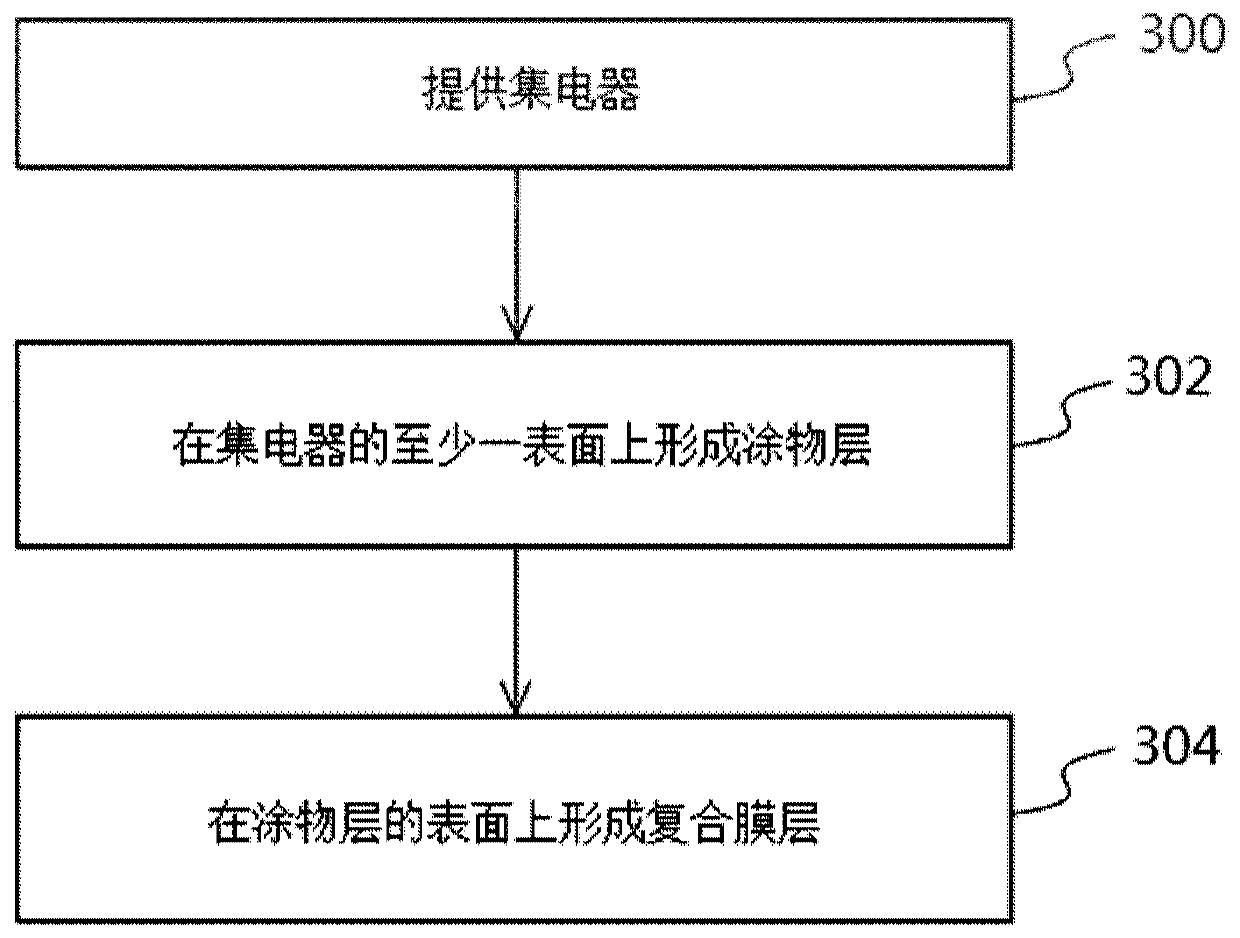

[0059] First, polyvinylidene fluoride (PVDF) powder is added into dimethylacetamide (DMAC) solvent to prepare a homogeneous solution of PVDF. The above-mentioned solvents correspond to solvents that can dissolve and form a homogeneous or uniform suspension solution according to different materials, for example: PVDF with DMAC solvent, PVDF with N-methylpyrrolidone (NMP) solvent or PTFE with ethanol (Ethanol) solvent . Subsequently, the homogeneous solution was evenly coated on the titanium sheet as the current collector by blade coating, and dried in an oven to completely evaporate the solvent, so as to form a PVDF layer as the first layer on the current collector. The water contact angle of the PVDF layer is captured by the fast camera according to the time change as follows: figure 2 The schematic diagram shown. From figure 2 It can be obtained that the water contact angle of the PVDF layer is 81.84° at 0 minutes and 54.13° at 50 minutes. In other words, the water cont...

experiment example 1

[0064] The electrode of comparative preparation example 1 and preparation example 1 is placed in 10m LiTFSI aqueous solution electrolyte, carries out cyclic voltammetry scanning with 1mV / s scan rate, obtains Figure 3A and Figure 3B . Figure 3A Show the cyclic voltammetry spectrum of the first circle of comparative preparation example 1 and preparation example 1; Figure 3B The cyclic voltammetry spectra of Comparative Preparation Example 1 and the 5th cycle of Preparation Example 1 are shown.

[0065] Depend on Figure 3A It can be obtained that the hydrogen production current in the first cycle of Comparative Preparation Example 1 at -1.8V (vs.Ag / AgCl) is about 25mA / cm 2 , while the hydrogen production current of Preparation Example 1 is about 0.25mA / cm in the first circle of voltage -1.8V (vs.Ag / AgCl). 2 . Therefore, at the same hydrogen production potential (-1.8V vs. Ag / AgCl), the hydrogen production current of the electrode of Preparation Example 1 is much lower t...

preparation example 2

[0068] Electrodes were fabricated in the same manner as in Preparation Example 1, but the titanium sheets were changed to aluminum foils.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com