Method for evenly cladding CoOOH on powdery nickel hydroxide electrode material surface

A technology of nickel hydroxide and electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient bonding between the coating layer and the product, the degradation of the electrochemical cycle performance of the material, and the coating layer is easy to fall off. Achieve the effects of good charge and discharge reversibility, improved conductivity, and environmentally friendly coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

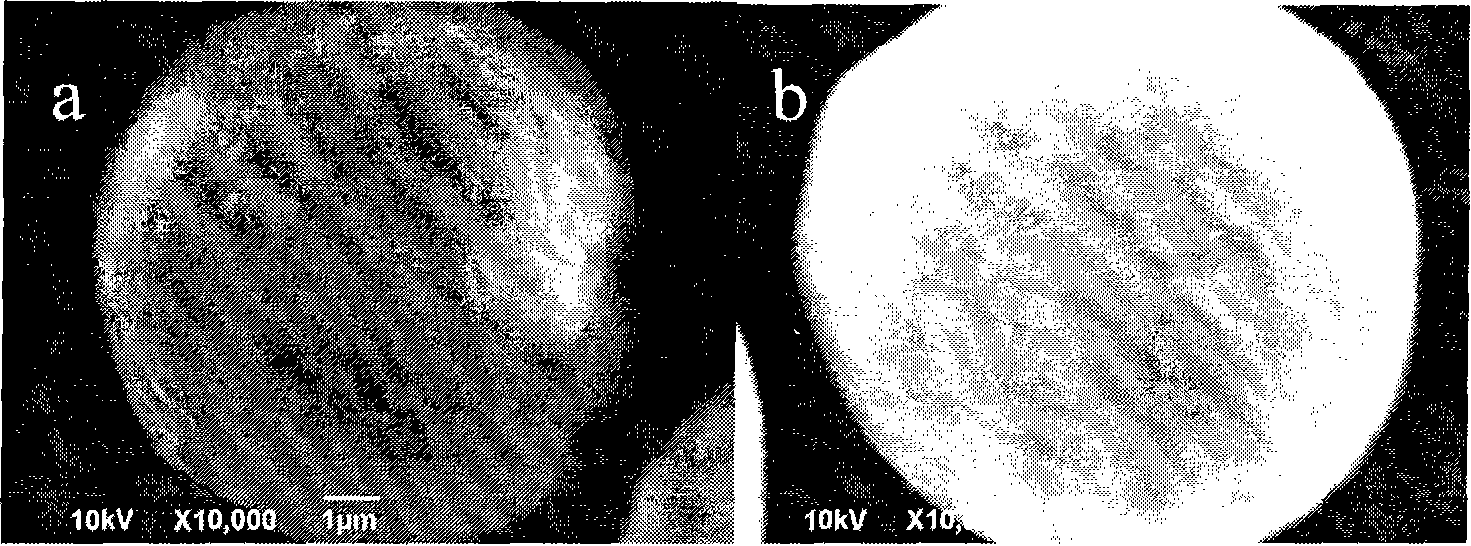

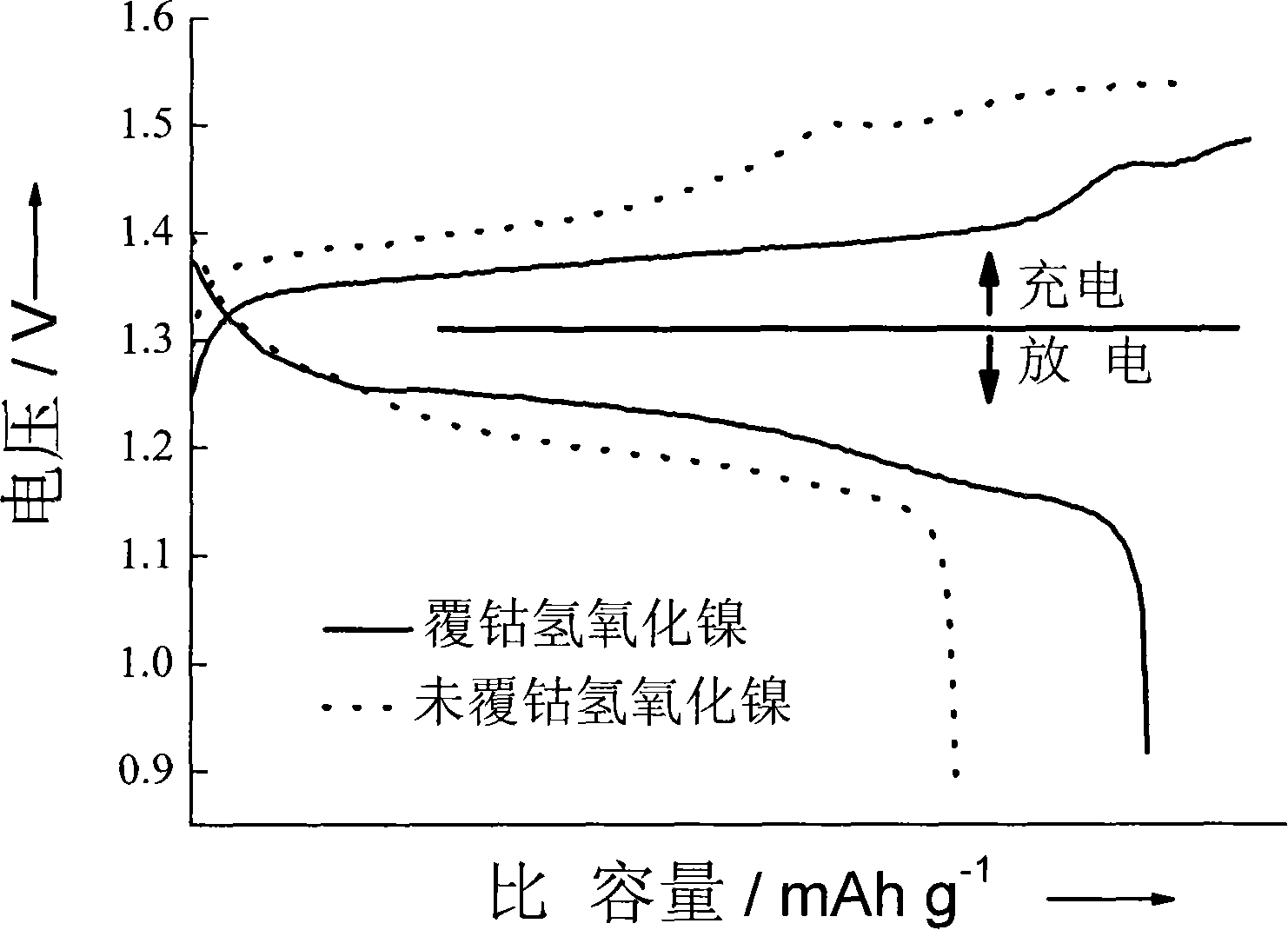

[0017] Example 1: First, dissolve 0.65g of cobalt nitrate in 50mL of distilled water in the reactor, add 1g of powdered nickel hydroxide, place the reactor in a water bath at 90°C, and add 8mL of 30% H 2 o 2 The aqueous solution was added to the reactor at intervals, and kept stirring for 2 hours. After natural cooling, filter, wash with pure water and ethanol, and then dry at 80° C. for 6 hours to obtain the powdered nickel hydroxide material uniformly coated with CoOOH. The average mass percentage of cobalt in the CoOOH-coated powdered nickel hydroxide material measured by plasma emission spectrometry (ICP) is 3.6%, and the molar ratio of nickel to cobalt is 15.33:1. The mass percent content of cobalt in the powdery nickel hydroxide raw material before coating CoOOH is 1.38%, and the molar ratio of nickel to cobalt is 38.44:1. What needs to be explained here is that the commercialized nickel hydroxide material is a composite material containing a certain proportion of Co i...

Embodiment 2

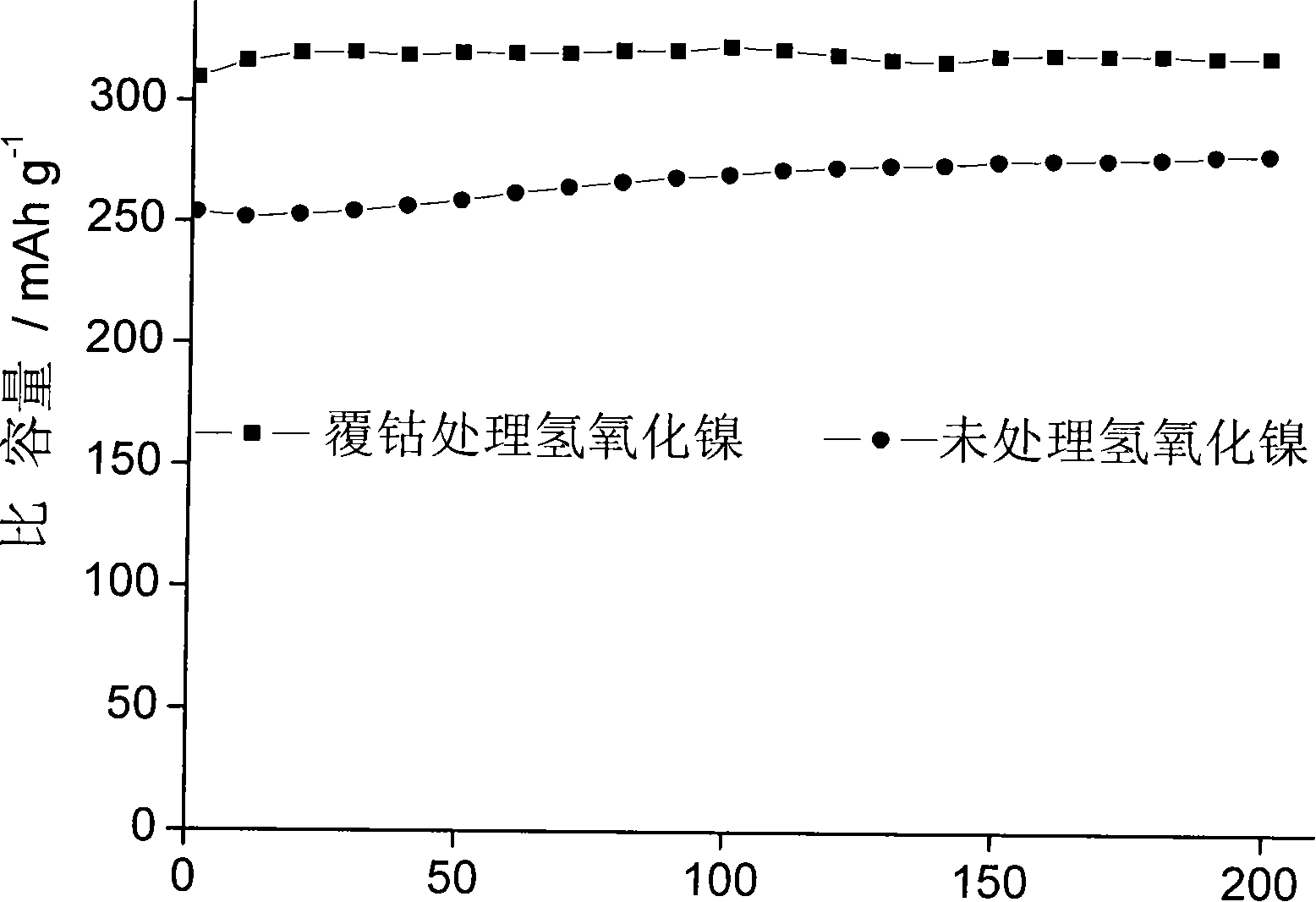

[0018] Example 2: First, dissolve 0.98g of cobalt nitrate in 50mL of distilled water in the reactor, add 1g of powdery nickel hydroxide, place the reactor in a water bath at 90°C, and add 12mL of 30% H 2 o 2 The aqueous solution was added to the reactor at intervals, and kept stirring for 2 hours. After natural cooling, filter, wash with pure water and ethanol, and dry at 80° C. for 6 hours to obtain the powdered nickel hydroxide material uniformly coated with CoOOH. The obtained material was made into a bonded electrode for charge and discharge tests, and the results showed that the 2C discharge specific capacity of the prepared CoOOH-coated powdered nickel hydroxide was 336mAh / g.

Embodiment 3

[0019] Example 3: First, dissolve 0.33g of cobalt nitrate in 50mL of distilled water in the reactor, add 1g of powdery nickel hydroxide, place the reactor in a water bath at 90°C, and add 12mL of 10% H 2 o 2 The aqueous solution was added to the reactor at intervals, and kept stirring for 2 hours. After natural cooling, filter, wash with pure water and ethanol, and then dry at 80° C. for 6 hours to obtain the powdered nickel hydroxide material uniformly coated with CoOOH. The obtained materials were made into bonded electrodes for charge and discharge tests. The results showed that the 2C discharge specific capacity of the prepared CoOOH-coated powdered nickel hydroxide was 341mAh / g, and the capacity after 200 cycles of charge and discharge at the 2C rate was No attenuation occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com