Max phase material for lithium ion battery anode and preparation method thereof

A lithium-ion battery and anode technology, applied in the field of materials, can solve problems such as limiting the practical application of MXene electrodes, and achieve excellent cycle stability and charge-discharge reversibility, simple synthesis method, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

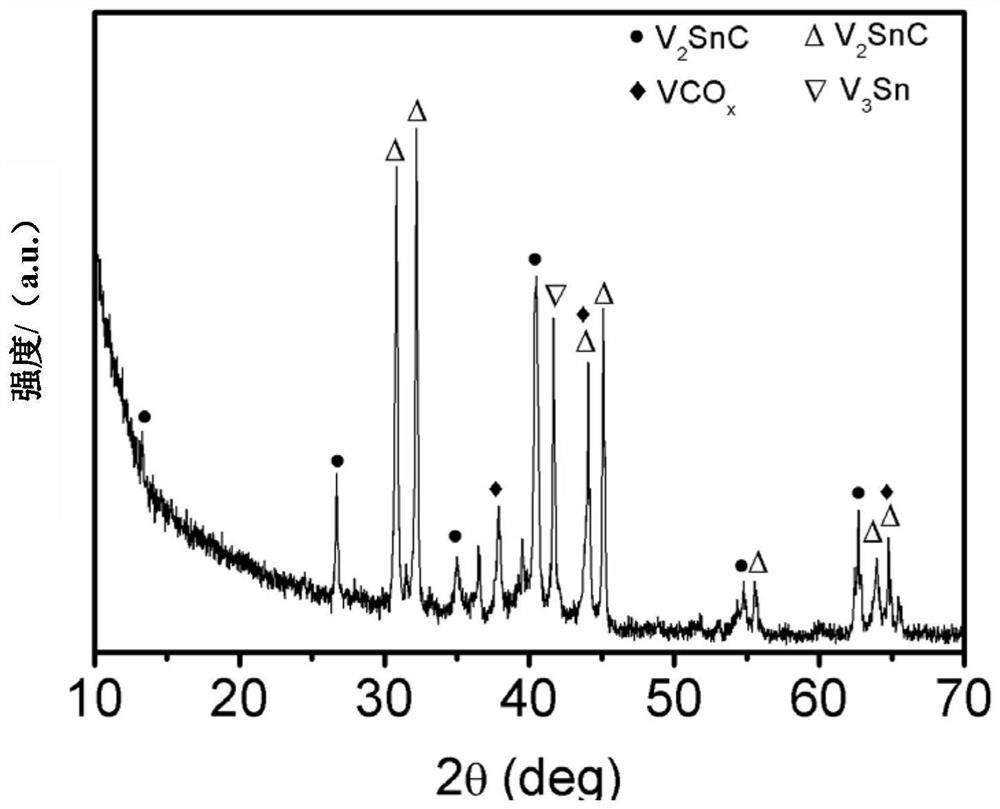

[0037] Embodiment 1: In this embodiment, the MAX phase material used for the lithium-ion battery anode is V 2SnC powder material, raw materials are V powder, Sn powder, graphite, inorganic salts are NaCl and KCl, and these raw materials can be obtained through commercial channels. The V 2 The preparation method of SnC powder is as follows:

[0038] (1) Mix V powder, Sn powder, graphite and inorganic salt (sodium chloride, potassium chloride) in a molar ratio of 2:1:1:0, grind and mix the above materials to obtain a mixed product.

[0039] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 600°C, 60 minutes, under the protection of argon. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0040] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, s...

Embodiment 2

[0043] Embodiment 2: In this embodiment, the MAX phase material used for the lithium-ion battery anode is V 2 SnC powder material, raw materials are V powder, Sn powder, graphite, inorganic salts are NaCl and KCl, and these raw materials can be obtained through commercial channels. The V 2 The preparation method of SnC powder is as follows:

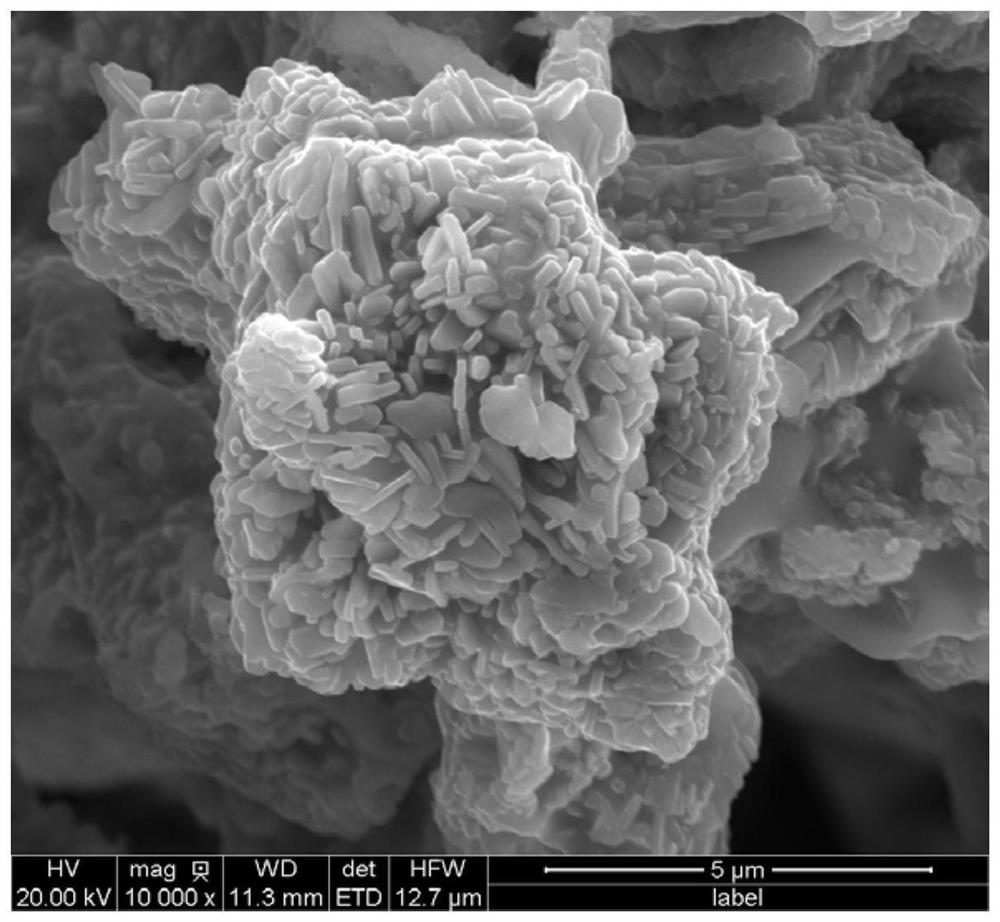

[0044] (1) Mix V powder, Sn powder, graphite and inorganic salt (sodium chloride, potassium chloride) in a molar ratio of 3:3:2:8, grind and mix the above materials to obtain a mixed product.

[0045] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 1000°C, 720 minutes, under argon protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0046] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, stir ...

Embodiment 3

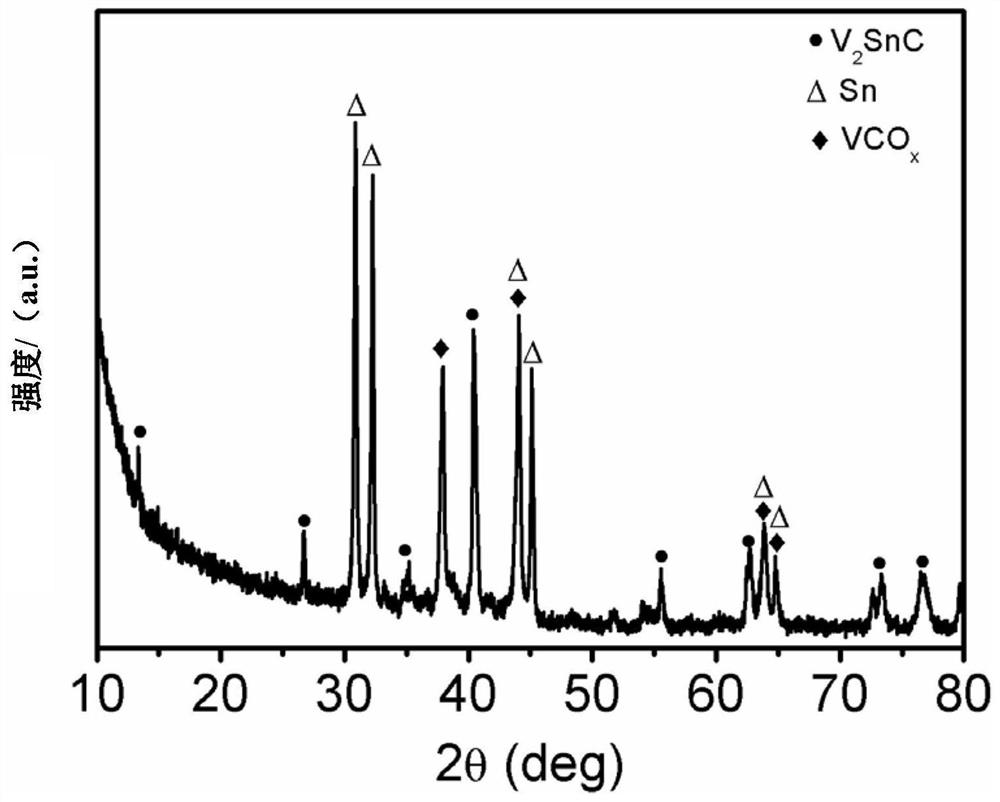

[0048] Embodiment 3: In this embodiment, the MAX phase material used for lithium-ion battery anode is V 2 SnC powder material, raw materials are V powder, Sn powder, graphite, inorganic salts are NaBr and KBr, and these raw materials can be obtained through commercial channels. The V 2 The preparation method of SnC powder is as follows:

[0049] (1) Mix V powder, Sn powder, graphite and inorganic salt (sodium chloride, potassium chloride) in a molar ratio of 3:1:2:4, grind and mix the above materials to obtain a mixed product.

[0050] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: 800°C, 420 minutes, under argon protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0051] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, stir and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com