Nano-sized nickel hydroxide/carbon composite material and its manufacture method and purpose

A carbon composite material, nickel hydroxide technology, applied in the direction of alkaline battery electrodes, etc., can solve the mismatch of the size ratio of nano nickel hydroxide particles and conductive agent particles, nano nickel hydroxide materials are prone to agglomeration, and the battery performance is not very good. Ideal and other problems, to achieve excellent high-current charge-discharge characteristics, good charge-discharge reversibility, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

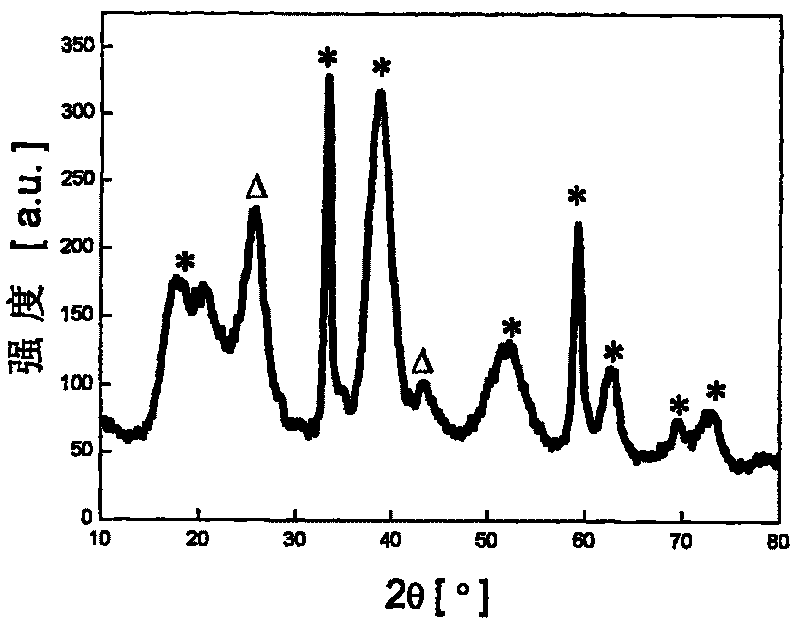

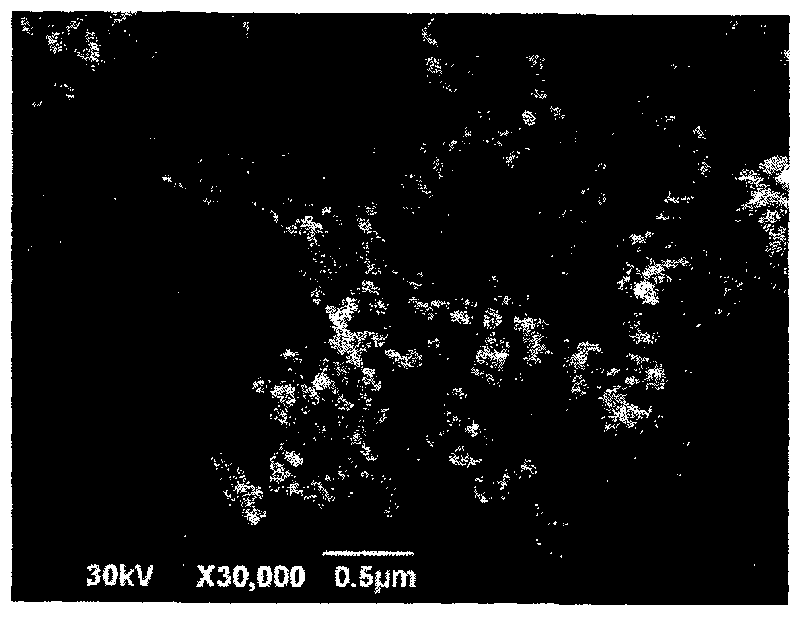

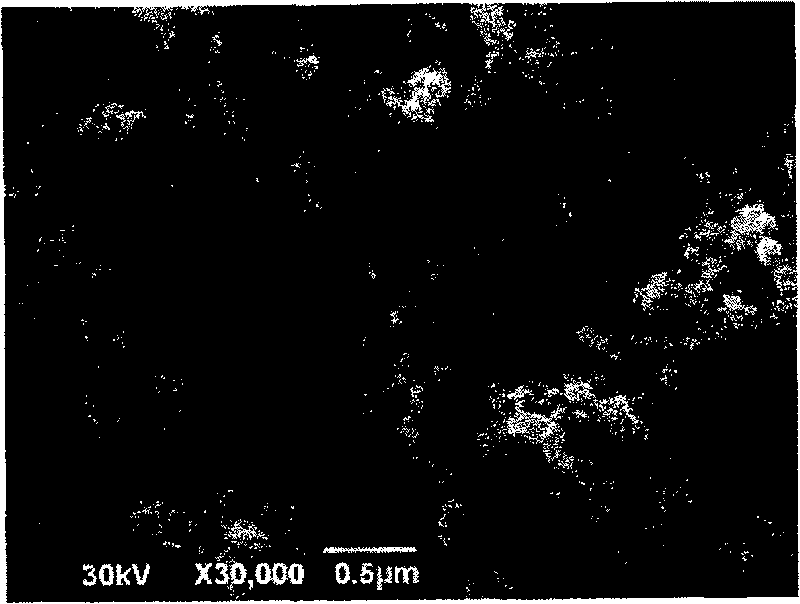

[0027] Embodiment 1: Preparation of nano-nickel hydroxide / carbon composite material whose weight percent content of nano-nickel hydroxide is 50%.

[0028] The base carbon material can be acetylene black, carbon black, graphite or amorphous carbon with a particle size of 0.001-50 microns. In this embodiment, acetylene black is taken as an example.

[0029] 1) Prepare NiCl with a concentration of 0.01-5.0mol / L 2 The solution is ready for use, and can also be nickel sulfate, nickel acetate or nickel nitrate solution of the same concentration;

[0030] 2) Prepare a KOH solution with a concentration of 0.1-5.0mol / L, or sodium hydroxide or LiOH solution with the same concentration;

[0031] 3) Preparation of nano-nickel hydroxide / carbon composite material: add acetylene black to the above-mentioned NiCl in proportion 2 In the aqueous solution, add ethanol or methanol, propanol, butanol, isopropanol, acetone, butanone with a volume of 0.5% to 5% of the volume of the above solution ...

Embodiment 2

[0032] Example 2: Preparation of nano-nickel hydroxide / carbon composite material with a weight percent content of nano-nickel hydroxide of 33.3%.

[0033]Taking acetylene black as the nano-nickel hydroxide weight percentage content of the base as the preparation step of the nano-nickel hydroxide / carbon composite material of 33.3% and the nano-nickel hydroxide / carbon composite material whose weight percentage content of the nano-nickel hydroxide is 50% The preparation steps are exactly the same, only the proportion of reactants required in the preparation process is different. The weight of the acetylene black added in the preparation process is twice the weight of the nano-nickel hydroxide generated in the preparation process. The cyclic curve of the prepared nano-nickel hydroxide / carbon composite ( Figure 5 ) shows that the oxidation peak potential of nickel is 0.460V, the reduction peak potential is 0.336V, and the peak potential difference is 0.124V, indicating that this ...

Embodiment 3

[0034] Example 3: Preparation of nano-nickel hydroxide / carbon composite material with a weight percent content of nano-nickel hydroxide of 66.7%.

[0035] Taking acetylene black as the nano-nickel hydroxide weight percentage content of the base as the preparation step of the nano-nickel hydroxide / carbon composite material of 66.7% and the nano-nickel hydroxide / carbon composite material whose weight percentage content of the nano-nickel hydroxide is 50% The preparation steps are exactly the same, only the proportion of reactants required in the preparation process is different. The weight of the acetylene black added in the preparation process is half of the weight of the nano-nickel hydroxide generated in the preparation process. The cyclic desk curve ( Figure 6 ) shows that the oxidation peak potential of nickel is 0.457V, the reduction peak potential is 0.334V, and the peak potential difference is 0.123V, indicating that this material also exhibits good conductivity and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com