Broad-spectrum and efficient cleaning agent for cooling system

A cooling system and cleaning agent technology, applied in detergent compositions, non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, etc., can solve problems such as ignoring silica gel scale cleaning, equipment safety hazards, cracking, etc. , to achieve the effect of excellent metal corrosion inhibition and protection of the cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

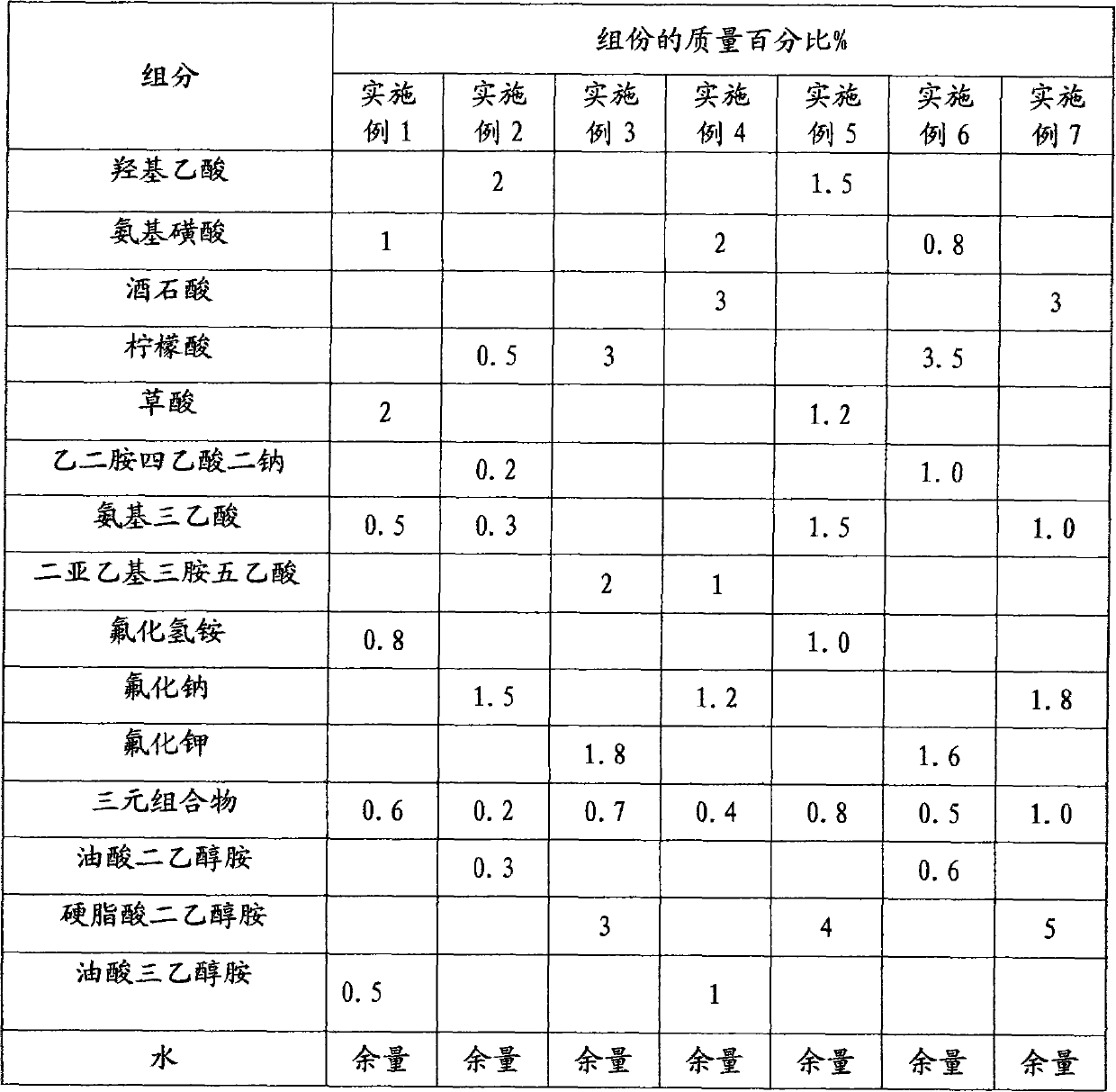

[0020] Embodiment 1-7 Preparation of broad-spectrum high-efficiency cooling system cleaning agent of the present invention

[0021] At room temperature, add organic acid, chelating agent, cleaning accelerator, and corrosion and scale inhibitor dispersant into quantitative water according to the ratio shown in Table 1, stir and mix evenly, then add degreasing agent, and adjust the pH value to 4-5 in between.

[0022] Table 1 Composition and proportion of broad-spectrum high-efficiency cooling system cleaning agent

[0023]

Embodiment 8

[0024] Embodiment 8 Cleaning comparison test of broad-spectrum high-efficiency cooling system cleaning agent of the present invention

[0025] Get the automobile cooling system cleaning agent 500g that above-mentioned any embodiment produces, after mixing and diluting with water 1: 10 (mass ratio), inject into cooling system; Start engine, after idling for 5 minutes, vehicle can run normally, and travels 1~2 hour , stop and drain the cooling system. Then fill the cooling system with clean water, start the engine and run it at idle speed for 5 minutes, then empty it. If the drain water is dirty, please rinse it with clean water until the drain water is clear.

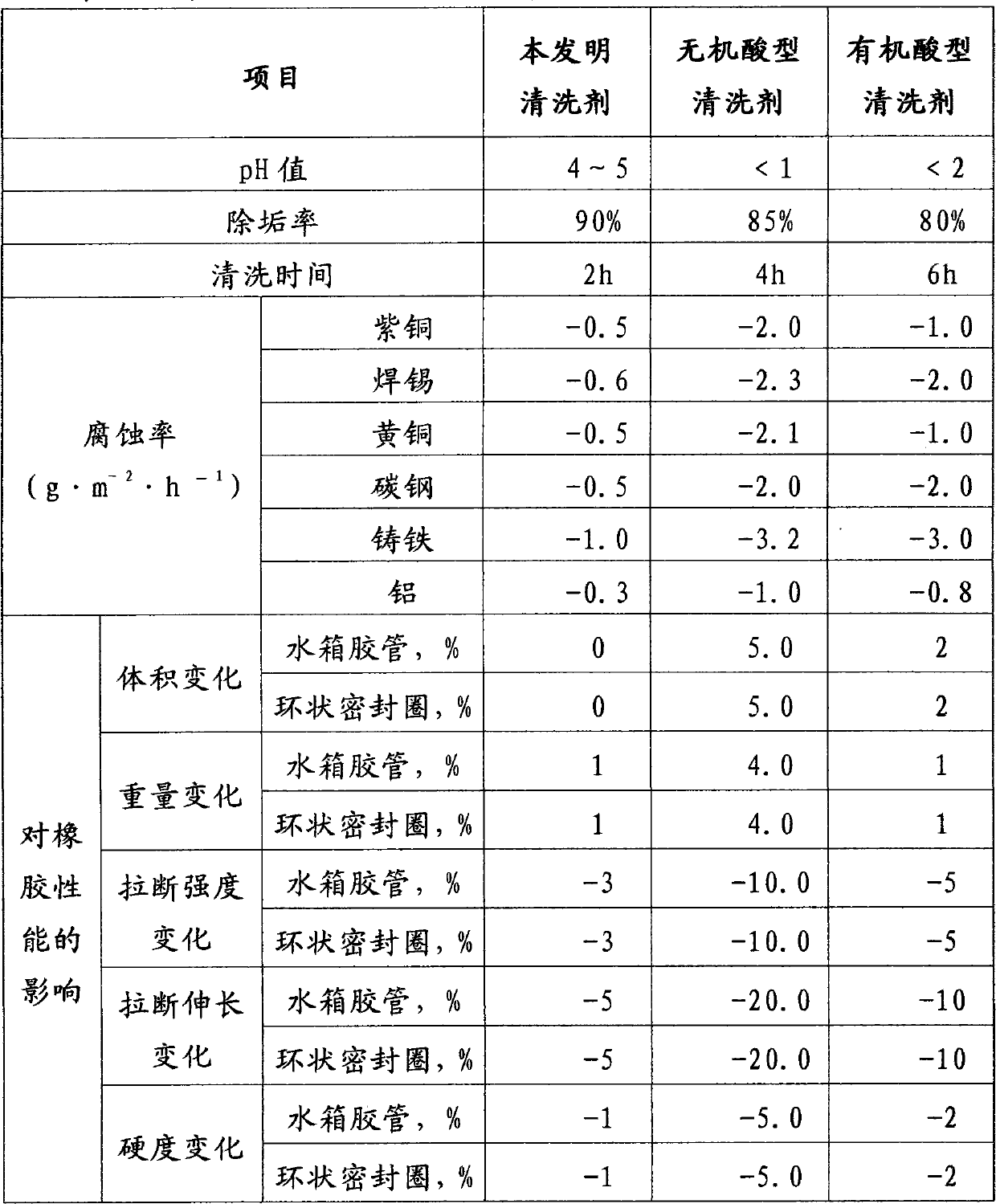

[0026] In order to prove that cleaning agent of the present invention is better than conventional cleaning agent, select conventional inorganic acid (LX-VII cleaning agent, hydrochloric acid content 8%) type cleaning agent, organic acid (LX-IX cleaning agent, sulfamic acid content 89%) type cleaning Table 2 shows the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com