Flying ash processing method

A treatment method, fly ash technology, applied in the direction of protective devices against harmful chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A fly ash treatment method of the present invention will be described in detail below in conjunction with a preferred embodiment.

[0017] According to a kind of fly ash processing method of the present invention, take the following steps:

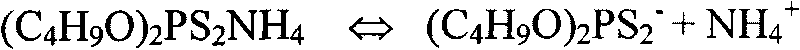

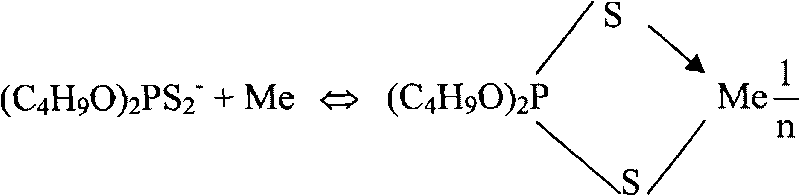

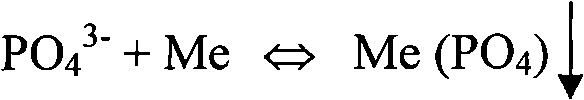

[0018] A. At an ambient temperature of 20°C, weigh a certain amount of fly ash, add sodium phosphate, aluminum sulfate, chitosan and butylamine black medicine to the fly ash in sequence, and add an appropriate amount of water. The ratio is 1:1, at 200 rpm, stir in JB90-D electric mixer, stop stirring after 10 minutes, put it in an oven for drying after 24 hours, and control the temperature at 50°C , forming fly ash chelates.

[0019] B. In order to improve the reaction effect, kaolin is calcined at a temperature of 800°C for 6 hours to make metakaolin, and at the same time, sodium hydroxide is dissolved in water glass to make an alkali activator, and metakaolin is mixed with fly ash chelate. The ratio of kaolin to fly ash chelate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com