Vinyl content method for controlling polybutadiene in elastomer

A technology of vinyl content and polybutadiene, which is applied in the field of elastomer preparation by anion polymerization method, can solve the problems of reducing the polymerization reaction speed, coupling reaction coupling efficiency, etc., and achieves the effect of easy control of industrial operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

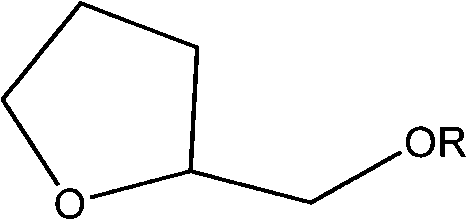

Embodiment 1

[0028] A 250ml three-necked bottle was used as the reaction vessel. Use a pipette to pipette 100ml of cyclohexane, accurately absorb 8g of butadiene, and add it to the reaction vessel. Use the binary composite regulator system of tetrahydrofurfuryl alcohol ethyl ether (hereinafter referred to as ATE) / PMDETA, add the consumption of ATE to be 0.027mmol, add the consumption of PMDETA to be 0.009mmol, add the n-butyllithium of 0.75mol / L concentration ( n-BuLi) initiator 0.12ml, the polymerization temperature is 65°C, and the polymerization time is 40min. After the polymerization is completed, the reaction is terminated with methanol, and then precipitated with methanol that is more than 5 times the amount of the solution to separate the polymer from the solvent. After drying, the polymer is tested by gel liquid chromatography (GPC), nuclear magnetic (NMR), etc. characterization. The measured 1,2-structure content was 30.3%, the number average molecular weight (Mn) was 88000, and...

Embodiment 2

[0030]A 250ml three-necked bottle was used as the reaction vessel. Use a pipette to pipette 100ml of cyclohexane, accurately absorb 10g of butadiene, and add it to the reaction vessel. Use the binary composite regulator system of tetrahydrofurfuryl alcohol ethyl ether (hereinafter referred to as ATE) / PMDETA, add the consumption of ATE to be 0.0338mmol, add the consumption of PMDETA to be 0.0338mmol, add the n-butyl lithium of 0.75mol / L concentration ( n-BuLi) initiator 0.15ml, the polymerization temperature is 65°C, and the polymerization time is 40min. After the polymerization is completed, the reaction is terminated with methanol, and then precipitated with methanol that is more than 5 times the amount of the solution to separate the polymer from the solvent. After drying, the polymer is tested by gel liquid chromatography (GPC), nuclear magnetic (NMR), etc. characterization. The measured 1,2-structure content was 46.4%, the Mn was 89100, and the MWD was 1.08.

Embodiment 3

[0032] A 250ml three-necked bottle was used as the reaction vessel. Use a pipette to pipette 100ml of cyclohexane, accurately absorb 12g of butadiene, and add it to the reaction vessel. Use the binary composite regulator system of tetrahydrofurfuryl alcohol ethyl ether (hereinafter referred to as ATE) / PMDETA, add the consumption of ATE to be 0.075mmol, add the consumption of PMDETA to be 0.015mmol, add the n-butyl lithium of 0.75mol / L concentration ( n-BuLi) initiator 0.2ml, the polymerization temperature is 65°C, and the polymerization time is 40min. After the polymerization is completed, the reaction is terminated with methanol, and then precipitated with methanol that is more than 5 times the amount of the solution to separate the polymer from the solvent. After drying, the polymer is tested by gel liquid chromatography (GPC), nuclear magnetic (NMR), etc. characterization. The 1,2-structure content was determined to be 39.5%, the Mn to be 81000, and the MWD to be 1.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com