Mixed acid type polyester polyol and preparation method thereof

A technology of polyester polyol and mixed acid, applied in the field of polyester polyol, can solve the problems of excess performance, dark color, poor performance and quality of polyurethane rigid foam products, etc., to improve compressive strength and dimensional stability, preparation Simple method and post-processing, and the effect of increasing the stability of miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 17 parts of terephthalic acid, 46 parts of adipic acid, 15 parts of ethylene glycol and 22 parts of 1,4-butanediol into the reactor equipped with a thermometer, oil-water separator and stirrer, and start charging before heating. Nitrogen protection for 10min. Heat to 225°C at a heating rate of 20°C / h, control the top temperature at 95±5°C, start vacuuming when the water output reaches 85% of the theoretical water output, control the vacuum degree to less than 0.096MPa, add 0.5 parts of titanic acid after 1h Tetrabutyl ester is subjected to polycondensation reaction, and when the acid value is 0.6 mgKOH / g, the reaction is stopped to obtain the product.

[0030] The obtained polyester polyol index of embodiment 1 is as follows: color<30#, acid value (mgKOH / g): 0.6, hydroxyl value (mgKOH / g): 56, water content is 0.03%, viscosity (75 ℃, cP): 680.

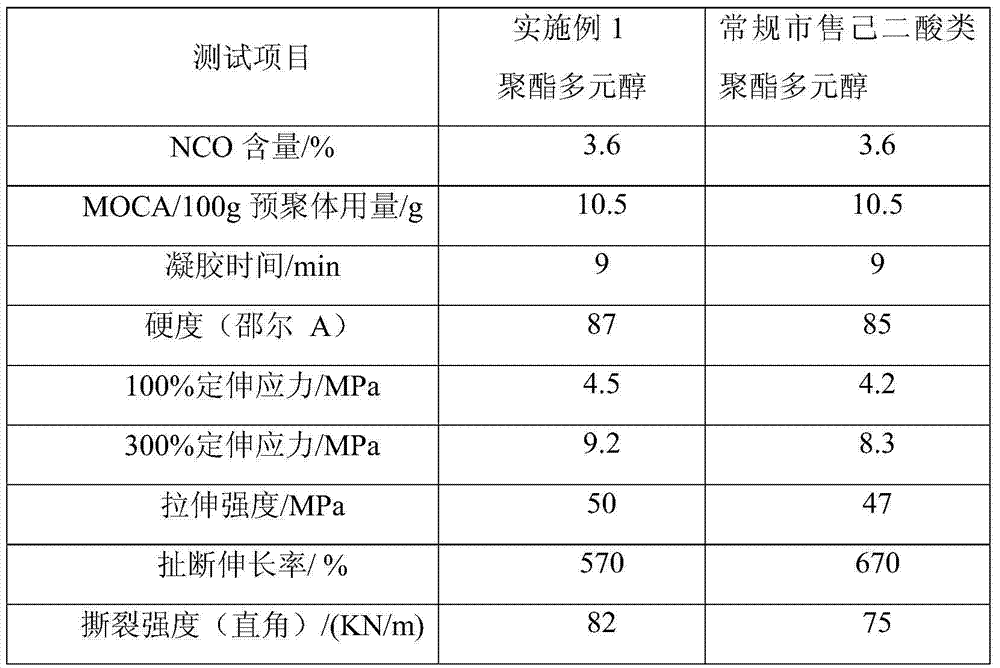

[0031] Apply the polyester polyol obtained in Example 1 to polyurethane elastomers, synthesize a prepolymer with an NCO c...

Embodiment 2

[0036] Add 38 parts of terephthalic acid, 7 parts of phthalic anhydride, 45 parts of diethylene glycol and 10 parts of glycerin into the reactor equipped with a thermometer, oil-water separator and stirrer, and start filling nitrogen for 10 minutes before heating. Heat to 220°C at a heating rate of 20°C / h, control the top temperature at 90±5°C, start vacuuming when the water output reaches 83% of the theoretical water output, control the vacuum degree to less than 0.096MPa, add 1 part of titanium after 1.2h Acid tetrabutyl ester and carry out polycondensation reaction, when the acid value is 1.0mg KOH / g, stop reaction, obtain product.

[0037] The obtained polyester polyol index of embodiment 2 is as follows: color<60#, acid value (mgKOH / g) is 1, hydroxyl value (mgKOH / g): 350, water content is 0.02%, viscosity (75 ℃, cP): 480.

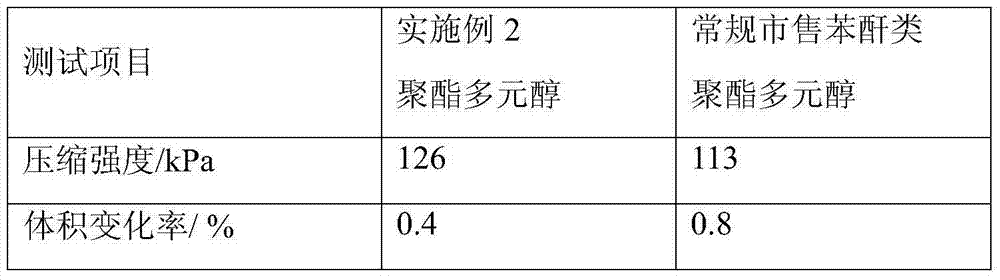

[0038] The polyester polyol obtained in Example 2 is applied to polyurethane rigid foam, and the foam compressive strength (the pressure value when t...

Embodiment 3

[0043] Add 11 parts of terephthalic acid, 29 parts of phthalic anhydride, 45 parts of diethylene glycol and 15 parts of triethylene glycol into the reactor equipped with a thermometer, oil-water separator and stirrer, and start filling nitrogen protection for 12 minutes before heating. Heat to 230°C at a heating rate of 20°C / h, control the top temperature at 95±5°C, start vacuuming when the water output reaches 85% of the theoretical water output, control the vacuum degree to less than 0.096MPa, add 1 part of octanoic acid after 0.8h stannous and carry out polycondensation reaction, when the acid value is 0.8mgKOH / g, stop the reaction to obtain the product.

[0044] The obtained polyester polyol index of embodiment 3 is as follows: color<60#, acid value (mgKOH / g): 0.8, hydroxyl value (mgKOH / g): 240, water content is 0.02%, viscosity (75 ℃, cP): 210.

[0045] Apply the polyester polyol obtained in Example 3 to rigid polyurethane foam, add 30 parts of cyclopentane or 50 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com