Extractive agent for depriving sulphide in C9 fuel oil and depriving method

A fuel oil and extractant technology, applied in the petroleum industry, refined hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix 20g of C9 fuel oil (see Table 1 for composition) and 20g of solvent diethylene glycol in a 250ml Erlenmeyer flask, stir at a constant temperature of 25°C for 30min, then transfer it to a separatory funnel and let it stand for 30min. Clear layers, the upper layer is The oil phase was weighed after washing with water, and the calculated yield was 91.8%. The total sulfur content of the oil phase was analyzed by microcoulomb method, and the sulfur content before desulfurization was 147ppm, and after desulfurization, the sulfur content was 135ppm, and the desulfurization rate was 8.2%.

[0024] Table 1 Composition of C9 fuel oil

[0025] components

Embodiment 2

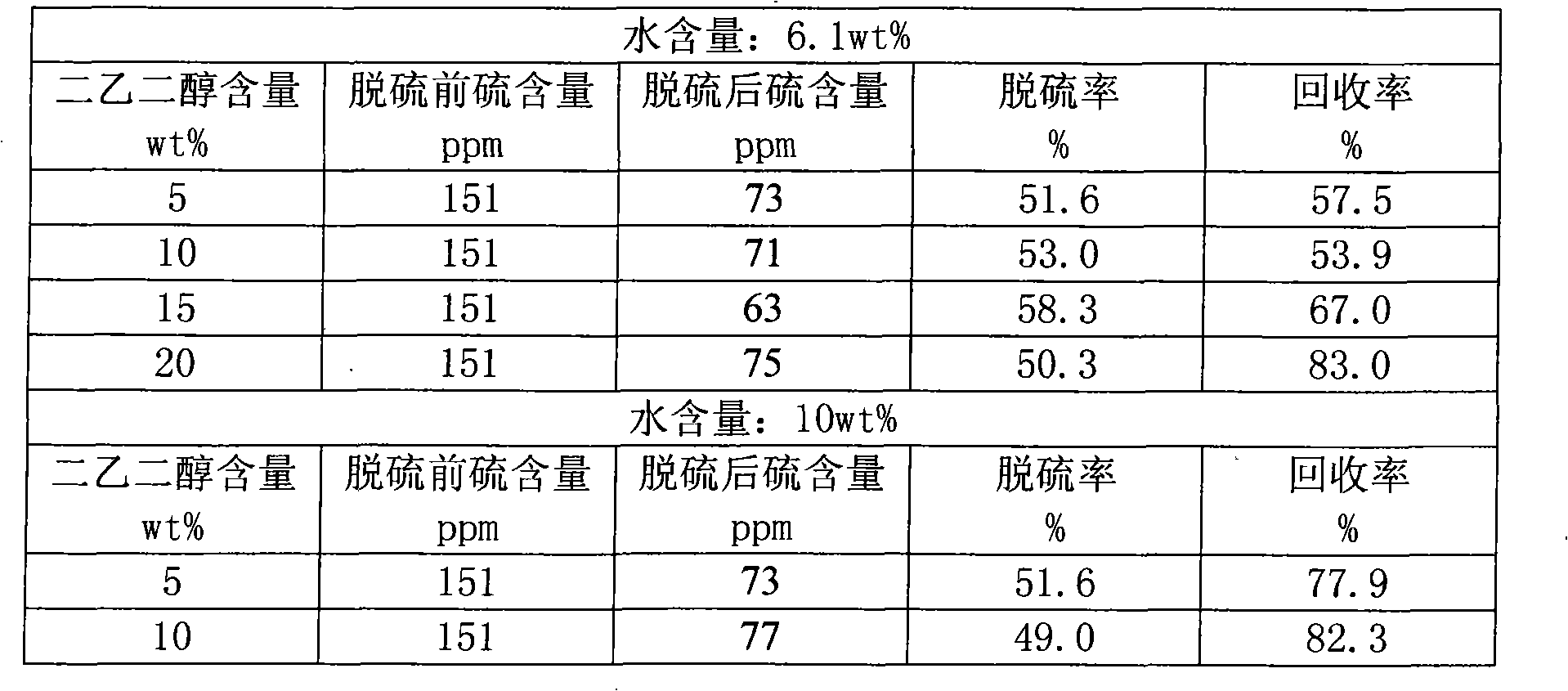

[0027] 20g carbon nine fuel oil and solvent are mixed in 250ml Erlenmeyer flask, containing water 10wt% in the solvent, all the other are N, N-dimethylformamide, the mass ratio of oil and solvent is respectively 2: 1, 1: 1, 1:2, stirred at 25°C for 30 minutes, then transferred to a separatory funnel and stood still for 30 minutes, clear layers, the upper layer was the oil phase, washed with water, weighed, calculated the yield, and analyzed the total sulfur content of the oil phase by microcoulometry , to calculate the desulfurization rate. The results are listed in Table 2. It can be seen from the table that the desulfurization rate of more than 30% can be achieved with an oil agent mass ratio of 2:1 to 1:2.

[0028] Table 2 Experimental results of extraction and desulfurization of C9 fuel oil with different mass ratios of oil agents

[0029] Oil mass ratio

Embodiment 3

[0031] Mix 20g C9 fuel oil with solvent in a 250ml Erlenmeyer flask, the solvent contains 10wt% water, the rest is N, N-dimethylformamide, the mass ratio of oil to solvent is 1:1, respectively, at 20°C , 30°C, 40°C, 50°C, 60°C, 70°C, stirred at constant temperature for 30min, then transferred to a separatory funnel and stood still for 30min, clear layers, the upper layer was oil phase, weighed after washing with water, calculated yield, micro The coulometric method was used to analyze the total sulfur content of the oil phase and calculate the desulfurization rate. The results are shown in Table 3. It can be seen from the table that when the extraction temperature is 20°C, 30°C, 40°C, 50°C, 60°C, and 70°C, the desulfurization rate and recovery rate are all better.

[0032] Table 3 Experimental results of extraction and desulfurization of C9 fuel oil at different temperatures

[0033] extraction temperature

[0034] 50

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com