High-speed rail bearing with high speed, heavy load and low friction

A low-friction, bearing technology, applied in the field of high-speed rail bearings, can solve the problems of bearing friction resistance and friction wear increase, raceway indentation, cage cracking, etc., and achieve the effect of reliable lubrication conditions, large bearing capacity and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

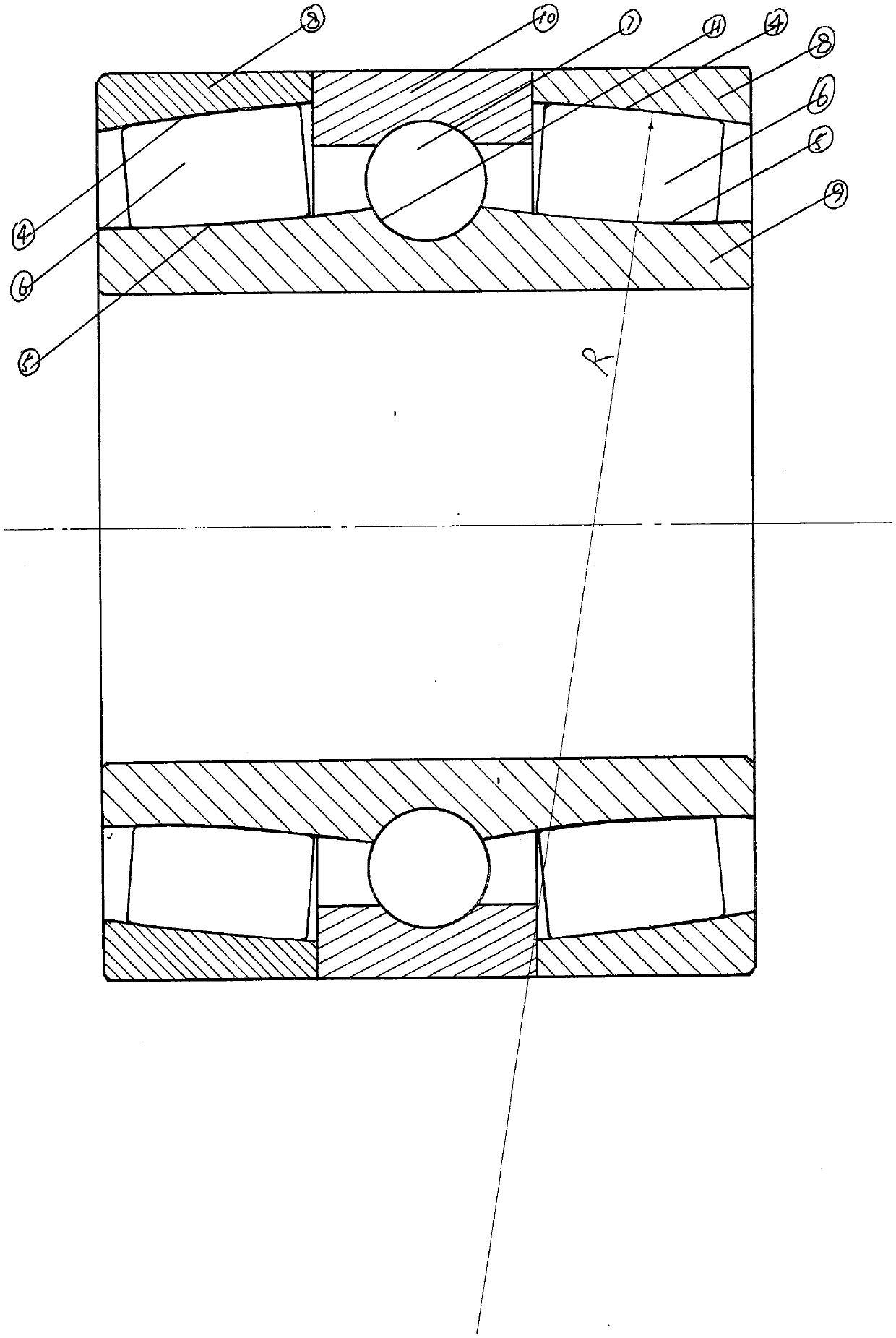

[0071] Such as figure 1 A high-speed heavy-duty low-friction high-speed rail bearing shown includes an outer ring 1, an inner ring 2 of a deep groove ball bearing, two double-half inner rings 3, a row of spherical rolling elements 7 and two rows of spherical rollers 6 , the inner circumference of the outer ring 1 is provided with a shared spherical roller track 4, the radius of curvature of the shared spherical roller track 4 is greater than the radius of the bearing roller circumferential track, so that the shared spherical roller track 4 set on the inner circumference of the bearing outer ring 1 The axial section has an olive-shaped elliptical ball bladder roller track structure, and a deep groove ball rolling body track 11 is provided in the middle of the inner circumference of the outer ring 1 sharing the axial distance of the spherical roller track 4,

[0072] The inner ring 2 of the deep groove ball bearing is arranged in the middle of the inner circumference of the oute...

Embodiment 2

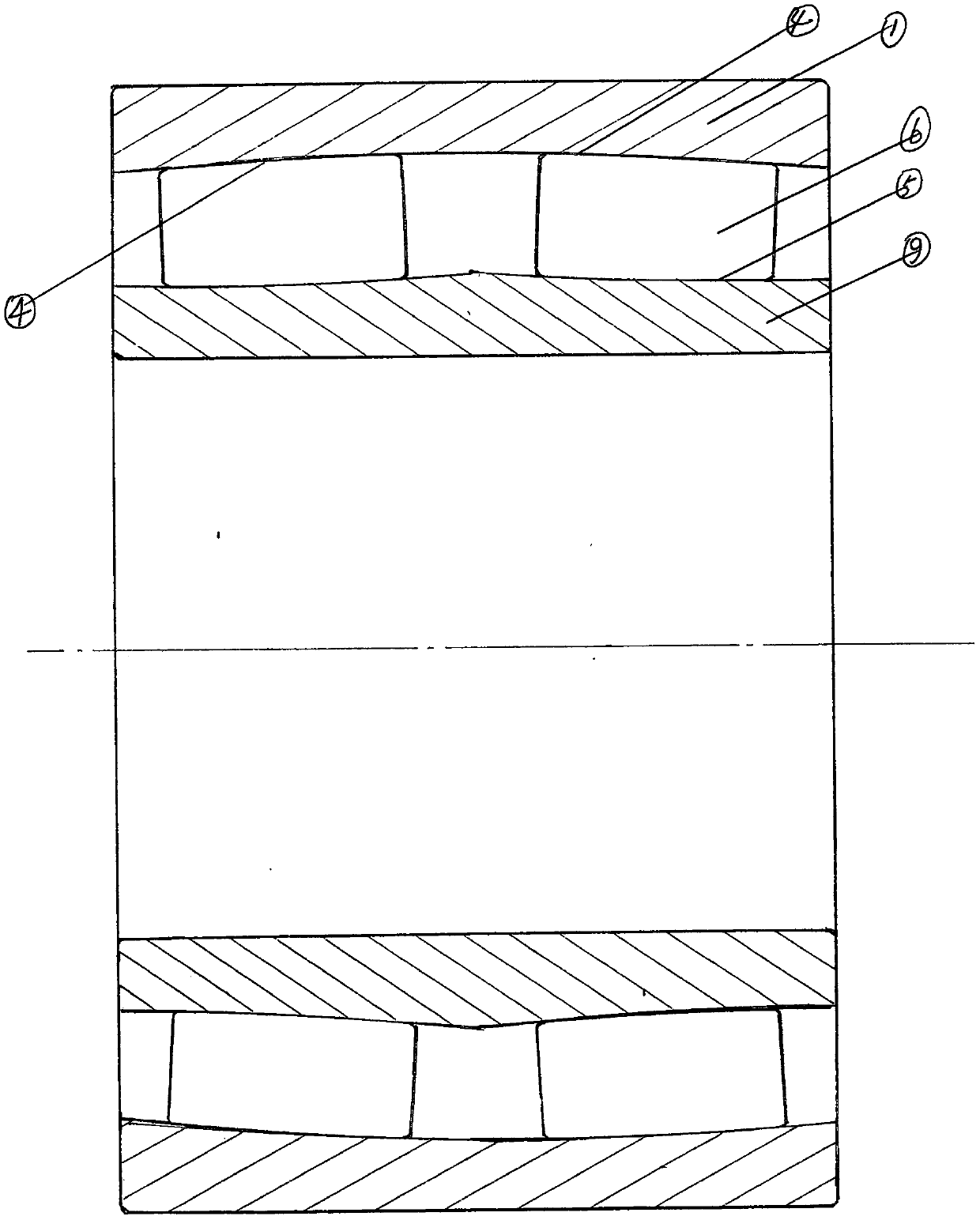

[0075] Such as figure 2 The high-speed heavy-duty low-friction high-speed rail bearing shown includes two double-half outer rings 8, an inner ring 9 and two rows of spherical rollers 6, and the inner circumferences of the two double-half outer rings 8 are respectively provided with spherical rollers. The sub-track, after the two double-half outer rings 8 are concentrically combined, the inner circumference forms a shared spherical roller track 4, and the radius of curvature of the shared spherical roller track 4 is greater than the radius of the bearing roller circumferential track, so that the shared spherical roller track The axial section of the roller track 4 has an olive-shaped elliptical bladder structure,

[0076] Two rows of spherical roller tracks 5 are arranged at an axial distance from the outer circumference of the inner ring 9. The two rows of spherical roller tracks 5 form an angle of 5 degrees with the vertical axis of the bearing, and each of the two rows of s...

Embodiment 3

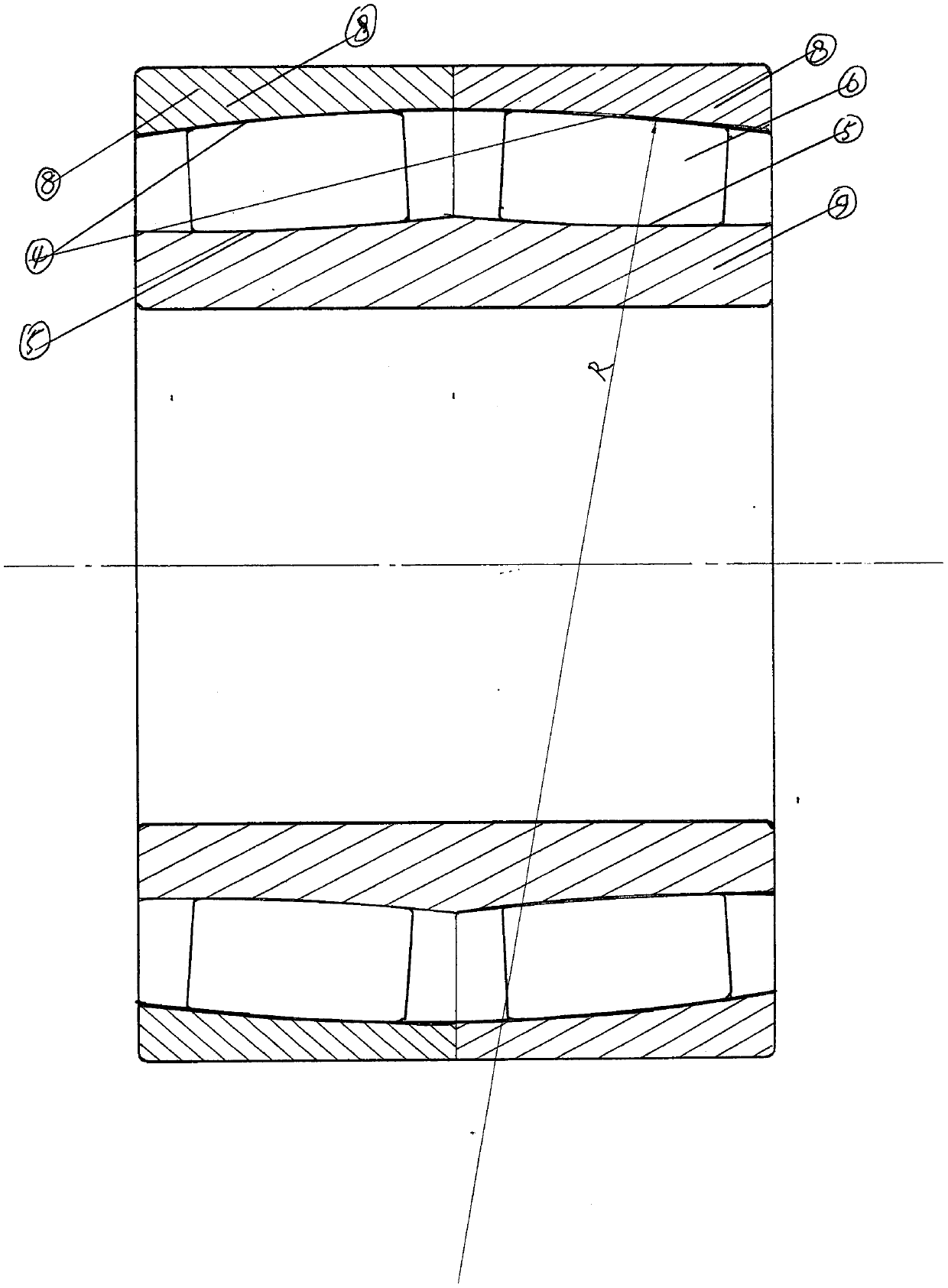

[0078] Such as image 3 A high-speed heavy-duty low-friction high-speed iron bearing shown includes an outer ring 1, an inner ring 9 and two rows of spherical rollers 6,

[0079] A shared spherical roller track 4 is arranged on the inner circumference of the outer ring 1, and the radius of curvature of the shared spherical roller track 4 is larger than the radius of the bearing roller circumferential track, so that the axial section of the shared spherical roller track 4 is an olive-shaped ellipse bile structure,

[0080] The outer circumference of the inner ring 9 is spaced apart from two spherical roller tracks 5, the two rows of spherical roller tracks 5 form an angle of 5 degrees with the vertical axis of the bearing, and each of the two spherical roller tracks 5 is provided with a row of spherical rollers. 6, the inner ring 9 is combined with the shared spherical roller track 4 provided on the inner circumference of the outer ring 1 through two rows of spherical rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com